Return to flip book view

1

DIG SAFE DIG DRY DUMP ON SITE STAY ON SITE 5 1 2 4 3 1 MTS MATERIAL DEPOSIT SYSTEM PATENTED WITH SIDE TIPPING CAPABILITY 2 MTS MULTI STAGE FAN TECHNOLOGY PATENTED WITH 24 000 CFM TWIN FAN SYSTEM 3 ROTARY VANE COMPRESSOR 360 CFM 185 PSI 4 HYDROSTATIC REMOTE CONTROLLED GROUND DRIVE 2

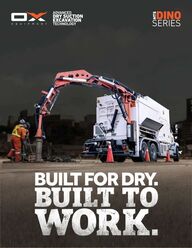

The innovative MTS Dino Series suction excavator is purpose built for dry from the ground up to powerfully and safely excavate without the use of water Utilizing patented technology and the highest quality components each unit is engineered and manufactured specifically to optimize performance and throughput Spend less time in the shop and more time working No leaving the jobsite to refill or dump wet spoils No costly slurry disposal charges No overweight loads Minimizing your travel and reusing excavated material effectively reduces your carbon footprint Unrivaled productivity Decreased costs Uncompromising safety Environmentally responsible 6 8 7 5 AUTOMATIC JET PULSE FILTRATION CLEANING 6 ROTATING OSCILLATING IKE EXCAVATION SYSTEM 7 10 DIAMETER SUCTION HOSE 8 REAR MOUNTED HYDRAULICALLY CONTROLLED POWER ARM Features listed do not apply to all truck configurations 3

BUILT FOR DRY FAN SYSTEM The MTS Dino Series of advanced suction excavators excels in air conveyance and material movement because of its patented multi stage twin fan technology This engineered feature delivers 24 000 CFM which is 4 to 5 times more air conveyance than the largest vac trucks on the market It also provides an advantage in optimizing dry material movement without compromising the integrity of the equipment unlike a positive displacement blower system which will be damaged by digging without water DEBRIS SYSTEM As dry materials travel through the air stream created by the immense suction power of this equipment it enters into a separation process that will sort materials internally Large debris will be broken down and impacted by a deflector plate which deposits in the main container allowing smaller debris and fines to continue on to a secondary debris cache The air conveyance remains unhindered and powerful through the filters and then exits the system as clean air COMPRESSOR SYSTEM With a rotary vane compressor adapted and sized for the MTS Dino Series users are ensured of continuous operation at performance levels that meet all demands Engineered for dry excavations the radiator and fan are dimensioned appropriately to protect from dust and sand while all electrical components are over dimensioned to withstand the high temperatures that come from long hours of usage All factors that result in a reliable and durable onboard compressor system 4

Decreased Project Costs Unrivaled Productivity Environmentally Responsible FILTRATION SYSTEM With the filtration system used by the MTS Dino Series the air flow remains clean which makes indoor facility or close proximity work ideal The conical system auto cleans during operation and is easily accessed and removable for more extensive maintenance The larger surface area of the filtration system effectively allows air conveyance to remain consistent and powerful while delivering long lasting use before ever needing to be replaced DIG TUBE AND ARM Having a 10 dig tube at the point of excavation means almost 300 more airflow at the point of excavation when compared to a typical vac truck This allows operators to process larger excavated materials more effectively and increases the amount of material that can be moved giving this equipment a superior overall dig rate The power arm and articulating control of the boom easily manages the dig tube and provides precision placement via remote which relieves any need for manual placement or maneuvering of the dig tube ONBOARD TOOLS Projects within the limits of utilities or buried infrastructure can encounter a variety of different materials which require more than one alternative for non destructive excavation The MTS Dino Series is equipped with a selection of lightweight pneumatic tools that are optimized by the onboard compressor system All tools are equipped with quickconnect fittings and are ideal for switching between tasks while increasing overall productivity 5 Uncompromising Safety

NEW FOR NORTH AMERICA MTS DINO4 5 The MTS Dino 4 5 LT includes the very features that set the Dino Series of suction excavators apart without the frills This unit combines over 20 years of proven engineering with the on site experience of North American workers TRUCK DIMENSIONS CONTAINER VOLUME VACUUM SYSTEM HYDROSTATIC DRIVE FILTRATION SYSTEM SUCTION HOSE CHASSIS AIR COMPRESSOR SUCTION HOSE CARRIER 29 x 8 x 12 ft Not equipped Western Star 4700 RAIL MOUNT KITS 6 yds 4 5 m Automatic Self Cleaning System Rotary Vane 360 cfm 185 psi 24 000 CFM Patented Multi Stage Technology 10 Diameter Power Arm MTS Dino Series suction excavators can be mounted on Hi Rail kits for all your rail work needs and when combined with hydrostatic drive gives your truck the capability to dig and drive similtaneously Side tipping functionality ensures efficiency as units can remain mounted on rails while disposing of material This coupled with the Dino s 24 000 cfm twin fan setup gives operators the power for all types of jobs including cleaning rail ballast accident debris and spilled loads cleanup railway demolition work and much more 6

MTS DINO4 5 Versatile in size impressive in power TRUCK DIMENSIONS CONTAINER VOLUME VACUUM SYSTEM HYDROSTATIC DRIVE FILTRATION SYSTEM SUCTION HOSE CHASSIS AIR COMPRESSOR SUCTION HOSE CARRIER 29 x 8 x 12 ft Wireless Remote Control Western Star 4700 6 yds 4 5 m Automatic Self Cleaning System Rotary Vane 360 cfm 185 psi 7 24 000 CFM Patented Multi Stage Technology 10 Diameter Mega Arm

MTS DINO8 A proven success in multiple industries TRUCK DIMENSIONS CONTAINER VOLUME VACUUM SYSTEM HYDROSTATIC DRIVE FILTRATION SYSTEM SUCTION HOSE CHASSIS AIR COMPRESSOR SUCTION HOSE CARRIER 36 x 8 x 12 ft Wireless Remote Control Western Star 4800 10 5 yds 8 m Automatic Self Cleaning System Rotary Vane 360 cfm 185 psi 8 24 000 CFM Patented Multi Stage Technology 10 Diameter Mega Arm

MTS DINO12 A top performer with added load capacities TRUCK DIMENSIONS CONTAINER VOLUME VACUUM SYSTEM HYDROSTATIC DRIVE FILTRATION SYSTEM SUCTION HOSE CHASSIS AIR COMPRESSOR SUCTION HOSE CARRIER 34 x 8 x 12 ft Wireless Remote Control Western Star 4800 16 yds 12 m Automatic Self Cleaning System Rotary Vane 360 cfm 185 psi 9 24 000 CFM Patented Multi Stage Technology 10 Diameter Mega Arm

MTS CITYDINO All the expected capabilities in a compact form TRUCK DIMENSIONS CONTAINER VOLUME VACUUM SYSTEM HYDROSTATIC DRIVE FILTRATION SYSTEM SUCTION HOSE CHASSIS AIR COMPRESSOR SUCTION HOSE CARRIER 25 x 7 5 x 11 5 ft Wireless Remote Control Western Star 4700 4 5 yds 3 5 m Automatic Self Cleaning System Twin 320 cfm 185 psi 10 10 500 CFM Patented Multi Stage Technology 8 Diameter Power Arm

The MTS Dino Series is the most versatile tool in safe digging Get positioned at the front of your industry with advanced suction excavation technology Railways Urban Infrastructure Pipelines Electrical Substation Industrial Road Work Roof Ballast Tree Root Protection 11

SPECIFICATIONS AIR COMPRESSOR TOOLS AND ACCESSORIES Power and Performance Productivity and Versatility Compressor Type Rotary Vane Air Spade Flow Pressure 360 cfm 185 psi 1x Air Spade 4000 Utility Series 5 extension Buffer Tank Capacity 15 Gallon 60L 150 225 280 CFM Nozzles Oiled Air Connection 1x Rear Non Oiled Air Connection 2x Rear Power Shovel 1x Vogt Pneumatic Shovel Tool Length 5 1 5 M with 5 5 Spade MEGA ARM Air Hose Length 24 6 7 5 m Precise Positioning Virtually Maintenance Free Jackhammer One 1 20kg with Spade and Chisel Mounting Location Rear 5 point articulating Safe Excavation Suction Tube Length 18 5 5m 26 7 9 m with extension Light weight HDPE with Urethane end Reducer Daylighting Yes 6 diameter Swivel Radius 180 Technical Tool Kit In eld adjustments repairs Construction Steel Welded Bolt Extension Tubes 6 Flexible Powered Yes 4 Rigid Hydraulic 45 suction tube adapter Remote Controlled Yes Suction Hose Diameter 10 IKE All Clear Excavations Rotating turntable dig tube attachment WIRELESS REMOTE CONTROL Continuous rotation or oscillation Manufacturer ABITRON Controls Boom and Tipping Operations Other 4x Double hook clamps Radio Controlled Functions 1x 60 inch IKE digging tube Compressor On Off TWIN FAN TECHNOLOGY Filter Cleaning On Off Patented Multi Stage System Boom to Tip Switch Type MTS F 42 000 Emergency Shutdown Power 315 HP 235 kW Motor Start Stop Reset Max Air Volume 24 000 CFM 42 000 m3 h Motor 3 Stage Speed Max Negative Air Pressure 13 Hg 44 000 Pa Hydrostatic Drive Fan Drive Split shaft PTO with processor controlled clutch engagement Storage Dedicated in cab remote storage with auditory proximity sensor alarm Fan Diameter 900 mm Hydrostatic Drive Fast Cut Shut Off Down Yes MTS FES Fuel Economy System Yes Operator remote control for drive reverse and steering functions Fan Bearing Lubrication Automatic Central Operate with suction on or off 2 5 mph 4km h max speed Front bumper sensor for auto stopping STABILIZERS Safety and Control Driver Dump Side 2x Passenger Power Arm Side 1x Operation Type Hydraulic All North American MTS equipment is built to DIN Standards and certi ed by TUV Features listed are subject to change Features listed do not apply to all truck configurations 12

HYDRAULIC SYSTEM STAINLESS STEEL CONTAINER Hydraulic Circuit 1 Power Arm Capacity 4 5 yds 6 yds 10 5 yds 16 yds Hydraulic Circuit 2 Air Compressor Construction NTZ Bypass Fine Filter Yes Return Filter Yes Replaceable Cartridge Container Inner Lid Stainless Steel Wear Parts ST 37 52 Hardox Hydraulic Oil HLP 46 of Compartments 2x Hydraulic Oil Tank Steel Powder coated Primary Compartment Cyclone Gravity Separation Temperature Sensor Yes Secondary Filter Compartment Finer material from lter Oil Level Indicator Yes Tip Direction Fluid Change Interval 500 hr service intervals after initial break in period Side Driver City Dino Rear Tip Tip Mechanism Hydraulic Tip Angle 45 degrees MTS High Capacity Filter System Self Cleaning Max Bin Height for Offloading 60 Number of Filters 42 HOSE REELS HOSE Filter Style Cone Conveniently Positioned Ease of Access Filter Material Polyester washable Rear Mount Non Oiled 1x HEPA compatible Yes Hose Length 33 10 m Filtration Efficiency TI 15 90 2 5 m 98 4 m Auto Re coil with brushes Yes Filter Cleaning System MTS Material Deposition System Patented 3 Stage high performance filter system based cyclone with electronically controlled auto cleaning pulse jet technology Two 2 Circuits for Independent Operation Debris Container Longevity FILTRATION PAINT Excluding Chassis Long Lasting Protection LIGHTING Pre nish Surface Prep Sandblasted Multi Layered Yes Paint Type 2K RAL Colors custom colors available STORAGE Safety and Visibility Organization and Accessiblity Rotating Safety Beacon Yes Cab Mounted Side Mounted Toolbox Yes Cab Mounted Rear Flashing Safety Lights Yes Toolbox Lining Rubber Mats 12V Power Socket 1x Rear Toolbox Lift Mechanism Gas Springs Optical Light Tower Yes Lockable Doors Yes Enhanced Safety Lighting 1x LED Light Power Arm Shaft 2x LED Lights Inside Toolbox 2x LED Lights Middle Segment Power Arm 3x LED Lights Positioned on Truck Frame Suction Tube Carrier Yes location model dependant ADDITIONAL FEATURES For More Safety Security and Satisfaction Lubrication Twin Fan System Automatic Lubrication Reverse Camera 180 view In cab LCD monitor Grounding Device Retractable Reel System 33 10 m cable pincer earthing screw spike Retractable Steel Ladder Truck Mounted allows for safe roof access Container Suction Hose Mounted Decanting Valve 1x Decanting Valve 1x Decanting Filter Box Suction Hose 4x Pnuematic powered Mudflaps Aluminum Dumping Container 2x Rear Bumper Integrated Receiver NOISE REDUCTION Air Exhaust Sound Silencer Air Outlet Machine House Anti noise Foam Plates Decibel Rating 85 dB 50 Ft rear of unit VIBRATORS 13

PARTS AND SERVICES Ox Equipment makes use of a state of the art facility stocked with the necessary replacement and repair components that ensure the high productivity rates of the MTS Dino Series suction excavators With MTS factory trained technicians that can diagnose and assess what your suction excavator needs to remain at optimal operating levels We re prepared to keep you working 14

Ox Equipment is the exclusive North American partner for MTS GmbH Suction Systems The combination of German engineered and manufactured equipment bundled with 5 Star North American service we offer a package that delivers complete peace of mind allowing you to bring top notch supplied service into your marketplace Ox Equipment will optimize the performance of your suction excavation equipment through proactive fleet management services based on expertise and innovation The Ox factory trained team is driven to get your business performing better than ever MTS GmbH has been manufacturing suction excavation equipment in Germany for over 20 years Today there are thousands of suction systems being used in 35 different countries worldwide and it is commonly referred to as the safest method of excavating around dense underground infrastructure Combining their years of engineering excellence with safe and efficient work practices make the MTS Dino Series a world leader in the vacuum excavation industry 15

4 5 yds 3 5 m 6 yds 4 5 m 6 yds 4 5 m 10 5 yds 8 m DINO12 MTS MTS MTS Container Volume DINO8 MTS DINO4 5 CITYDINO 16 yds 12 m Rotary Vane Compressor 24 000 CFM Twin Fan System 10 500 CFM 10 Diameter Suction Hose Power Arm Hose Carrier Mega Arm Hose Carrier Self Cleaning Filtration System Western Star Chassis Wireless Remote Hydrostatic Drive Contact Us Tel 888 290 4044 Email info ox equipment com Web ox equipment com PERFORMANCE DRIVEN 16