Return to flip book view

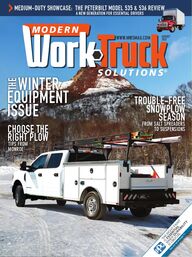

WINTER EQUIPMENT ISSUETHEWWW.MWSMAG.COMMEDIUM-DUTY SHOWCASE: THE PETERBILT MODEL 535 & 536 REVIEW A NEW GENERATION FOR ESSENTIAL DRIVERS CHOOSE THE RIGHT PLOWTIPS FROM MONROETROUBLE-FREE SNOWPLOW SEASONFROM SALT SPREADERS TO SUSPENSIONS AUGUST2021

CONNECT WITH US on Twitter (@mwsmag), Facebook (www.facebook.com/modernworktruck), and LinkedIn (www.linkedin.com/company/modern-work-truck-solutions).INDUSTRY NEWS ................................8INDUSTRY INSIGHT ........................... 14PRODUCT SHOWCASE ...................... 42IN EVERY ISSUEDAKOTA BODIES A BODY FOR EVERYBODY Get everything you need with smart and flexible work truck solutions from Dakota Bodies. Custom or standard, large or small fleet, steel or aluminum, Dakota Bodies has you covered.www.dakotabodies.com INSIDE THIS ISSUEAUGUST 2021 VOL-6 NO-840LIGHT-DUTYLIGHT-DUTY SAFETY TRAINING TRAINING LIGHT-DUTY DRIVERSA FUEL FOR THE WINTER .................. 44COVER STORIESFUEL CONTAMINATION TEST ARE YOU BUGGED?HEAVY-DUTY26PETERBILT MODEL 535 & 536 A NEW GENERATION16MEDIUM-DUTY WINTER EQUIPMENT ISSUETHEWWW.MWSMAG.COMMEDIUM-DUTY SHOWCASE: THE PETERBILT MODEL 535 & 536 REVIEW A NEW GENERATION FOR ESSENTIAL DRIVERS CHOOSE THE RIGHT PLOWTIPS FROM MONROETROUBLE-FREE SNOWPLOW SEASONFROM SALT SPREADERS TO SUSPENSIONS AUGUST2021SHOWCASEOPERATIONSTROUBLE-FREE SNOWPLOW SEASON .....20 From salt spreaders to suspensions OPERATIONSCHOOSE THE RIGHT PLOW ..................24Tips from Monroe WINTER EQUIPMENT ISSUETHE

MAINTENANCEHOW TO ENCOURAGE DRIVERS TO KEEP TIRES INFLATED .......30Educate, incentivize, communicateMAINTENANCEOPERATING AND MAINTAINING WORK TRUCKS IN SUBZERO WEATHER ..........................................................32Tips for a safe and compliant fleetTECHNOLOGYFUELING BUSINESS TRANSFORMATION .................................34How even the most complex fleet management and leasing business can automate at speed and scaleTECHNOLOGYFIGHTING TRAFFIC AND CONGESTION ....................................36Employ smart trip planningFEATURED PRODUCTDAKOTA BODIES ....................................................................43Get everything you need with smart and flexible work truck solutionswww.mwsmag.com P.O. Box 660197 Birmingham, Alabama 35266DONNA CAMPBELL Editor in Chiefdonna@mwsmag.com JADE BRASHER Editorjade@mwsmag.comRANDY MOON Associate Publisher randym@mwsmag.comVAL CARRIER Media Consultantval@mwsmag.comGARY BARKER Media Consultantgary@mwsmag.comTIM O’HARA Media Consultanttim.ohara@mwsmag.comLISA AVERY Art Director lisa@mwsmag.comCAMILLE BLACK Graphic Designer camille@mwsmag.comSETH SAUNDERS Digital Media SpecialistINGRID BERKY Office ManagerNo part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopy, recording, or any information storage-and-retrieval system without permission in writing from the publisher. The views expressed by those not on the staff of Modern WorkTruck Solutions, or who are not specifically employed by Highlands Publications are purely their own. All Industry News material has either been submitted by the subject company or pulled directly from its corporate website, which is assumed to be cleared for release. Comments and submissions are welcome, and can be submitted to jade@mwsmag.com.SUBSCRIPTIONS FOR ALL CHANGES, GO TO MWSMAG.COMCLICK THE "SUBSCRIPTIONS" BUTTON IN THE MAIN MENUCHRIS GARMONCFO DONNA CAMPBELLVP, Editorialwww.highlandspublications.com 312 Lorna Square Birmingham, AL 35216866.251.1777TIM GARMONCEORUSSELL HADDOCKPresidentTONYA BROWNINGVice President30 32Although it might be warm outside and we’re all still making Labor Day plans, winter is fast approaching. It’s never too early to start preparing for the busy season ahead—especially for those of us who work in the snow removal industry or have to ready a fleet for cold months to come. Our August issue is dedicated to winter equipment and all things related. Check out our cover stories about winter prep from salt spreaders to suspensions on page 20 as well as how to choose the right snowplow on page 24. If you maintain fleet trucks, flip on over to page 32 for tips on how to best maintain and operate trucks in subzero weather. And if you work in a climate that’s moderate year-round, we didn’t leave you out. Check out our pieces on fleet management for everyone on pages 34 and 36. There’s so many great pieces in this issue. Let us know your favorite by connecting with us via email or our social channels. Happy learning!Jade Brasher EditorEDITOR’S NOTETalk soon! Jade4336

SUBSCRIPTIONS FOR ALL CHANGES, GO TO MWSMAG.COMCLICK THE "SUBSCRIPTIONS" BUTTON IN THE MAIN MENU

MODERN WORKTRUCK SOLUTIONS WWW.MWSMAG.COM AUGUST 20218INDUSTRY NEWSNEW REFLECTIVE VEEBOARDS FROM KINEDYNE BOOST SAFETY BY ILLUMINATING CARGO SECURED ON TRAILERSNew reflective cargo corner protector VeeBoards® from Kinedyne increase safety by illuminating cargo strapped on an open-deck trailer. The VeeBoards help operators, motorists, and pedestrians see the trailer and load day or night. These bright orange reflectors need no batteries, but emit a strong glow from the reflected light of oncoming traffic. VeeBoards help protect valuable cargo from damage caused by overtightening winch and ratchet straps. Veeboards also protect load securement straps from sharp edges on cement, steel, and wood to help extend strap life. The heat-resistant corner protectors are effective in a wide range of temperatures and operating environments. The reflective 11-inch VeeBoards feature a stackable design that lets the VeeBoards sit atop each other in a neat and organized pile to easily be secured when not in use. For more, visit www.kinedyne.com. NATION’S CAPITALPeterbilt Motors Company visited Washington, DC while displaying the battery electric Model 579EV to government officials and members of Congress. The visit began with a press conference where US Energy Secretary Jennifer Granholm announced $60 million to fund 24 projects. The projects include those directly related to reducing emissions through battery and electrification technologies used within the transportation industry. Following the press conference US Commerce Secretary Gina Raimondo took the Model 579EV for a ride around the Capitol. The ride was part of a video with Energy Secretary Granholm and White House National Climate Advisor Gina McCarthy. The next day, Peterbilt displayed the Model 579EV at Peace Monument at the steps leading to the Capitol building. Several members of Congress stopped by during the day including Senator Ted Cruz as well as Senator Tom Carper. For more, visit www.peterbilt.com. STERTIL-KONI FLOOR PIT JACKS WITH A HYDRAULIC TELESCOPIC PISTON DELIVER SAFE, DEPENDABLE WHEELS-FREE LIFTING ACROSS NORTH AMERICAStertil-Koni provides a heightened level of safe, dependable, and durable lifting in workshops across North America using below-floor concrete pits with air hydraulic pit jacks—equipped with telescopic pistons—engineered by Stertil-Koni. Stertil-Koni engineered its free-standing rolling pit jack products that now deliver a lifting capacity of 33,000 lbs. Stertil-Koni designed these jacks specifically to safely

MODERN WORKTRUCK SOLUTIONS WWW.MWSMAG.COM AUGUST 202110INDUSTRY NEWSoperate on the pit floor, independent of pit edges or walls for support. Stertil-Koni designed it this way because these surfaces might not be strong enough to support the jack. For more, visit www.stertil-koni.com. LOVE’S TRAVEL STOPS OPENS TIRE RETREAD PLANT IN EL RENO, OKLAHOMALove’s Travel Stops opened a tire retread plant and distribution center in El Reno, Oklahoma. The 220,000-sq-ft facility doubles the size of the one it replaces in Grand Prairie, Texas. The size allows Love’s Truck Care and Speedco to increase capacity and better serve customers. Love’s has seven plants across the country and is expanding its retread plant and distribution center capacity. The plans will increase the company’s commitment to ensuring customer access to tires and parts. The Love’s retread process encompasses a comprehensive casing inspection regimen. Combined with the latest technology and a rigorous manufacturing process ensures a reliable and consistent product. An innovative and transparent casing repair program complements the quality retread tire. The program is consistent with a fleet’s specifications and a customized reconditioning/mounted wheel program. For more, visit www.loves.com. SUMMIT QUALITY MANAGEMENT Summit Truck Bodies, a US manufacturer supplying service truck solutions, earned ISO 9001:2015 certification for its quality management system. Summit Truck Bodies certification scope includes design, manufacturing, and assembly of truck bodies at the Wathena, Kansas facility. Lou Dreon, the policy and procedures supervisor at Summit, is responsible for maintaining the NTEA MVP status and achieving the ISO9001 certification. This certification reinforces Summit’s commitment to deliver a superior customer experience and develop and maintain successful partnerships. It also reinforces Summit’s commitment to meet needs through a customer-focused buying process, high-quality manufacturing, and exceptional after-sales support. For more, visit www.summitbodies.com. CHEVRON INTRODUCES DELO SYN Chevron Products Company launched Delo Syn ATF 668, a fully synthetic transmission fluid engineered for Allison heavy-duty automatic truck transmissions. Chevron engineered Delo Syn ATF 668 for longer service life, improved transmission performance, optimal fluid performance, and improved clutch operation. Allison approved and licensed Delo Syn ATF 668 for transmissions requiring TES 668; it is also backwards compatible with TES 389® and TES 295®. Manufactured with synthetic base oils

MODERN WORKTRUCK SOLUTIONS WWW.MWSMAG.COM AUGUST 202112INDUSTRY NEWSand state-of-the-art additives, it is a next-generation fluid for modern Allison transmissions. Additionally, this builds and improves on the proven performance of TES 389 and TES 295 fluids. For more, visit www.chevronlubricants.com. DUTY MODEL PRODUCTION AT The Kenworth new medium-duty models are now in production at the PACCAR assembly plant in Ste-Thérèse, Québec. The new medium-duty conventionals include the Kenworth T180, T280, T380, and T480. The new T380V and T480V models are for vocational applications. The Kenworth vehicles are available with the 6.9-L PACCAR PX-7 and 8.9-L PACCAR PX-9 engines. Kenworth also offers the near-zero emission Cummins Westport 8.9-L L9N natural gas engine as an option. The trucks feature the new, robust yet lightweight, PACCAR TX-8 automatic 8-speed transmission as standard. The transmission can handle 1,000 lb-ft of torque with 57,000-lb GCWR when matched to the PACCAR PX-7 or PX-9 engine.The new trucks offer three hood types to support the lineup’s application versatility: short aero hood (107.5-inch BBC) that accommodates front axles from 8K to 20K lbs; medium aero hood (109.5-inch BBC) for higher horsepower and AWD applications; and Kenworth’s vocational ‘sloped’ hood for the T380V and T480V, which employ a fixed grille for front engine PTO operations. The shorter wheelbases produce a tighter turning radius as well as enhanced maneuverability for urban or vocational operating environments. For more, visit www.kenworth.com. COUNTERFEIT GOLD CERTIFICATION LABEL FOUND IN ONTARIO, CANADAThe Automotive Lift Institute (ALI) warns of counterfeit gold “Certified Automotive Lift” labels applied to automotive lifts. The following is a safety notification from ALI that certain automotive lifts from Budget Automotive Equipment Inc. installed in Ontario and possibly other Canadian provinces or US States may bear a fraudulent declaration of compliance and product certification intended to mislead lift purchasers, users, and Authorities Having Jurisdiction. ALI advises that a Nationally Recognized Testing Laboratory (NRTL) has not evaluated automotive lifts bearing the gold label above. Therefore, the claim “Conforms to the provisions of ANSI standards” is untrue. ANSI authorizes only accredited certification agencies to use its certification mark. As of this safety bulletin, ANSI has accredited only the Automotive Lift Institute for automotive lift evaluations. The use of ANSI’s mark is inappropriate and not authorized for use by Budget Automotive Equipment Inc. For more, visit www.autolift.org.

MODERN WORKTRUCK SOLUTIONS WWW.MWSMAG.COM AUGUST 202114INDUSTRY INSIGHTAQSHAWN WHITACREMWS: WHAT IS ‘WINTERIZATION’ AND WHY IS IT HEARD SO OFTEN IN THE FLEET INDUSTRY?WHITACRE: Winterization in general refers to preparation one makes to equipment in advance of cold weather. It means being prepared for the unknown. The biggest challenge is that weather itself is often unpredictable—even more so when a fleet vehicle travels all directions at any given time. The vehicle could encounter all kinds of climates, especially during the transition seasons of spring and fall. Winterization is almost always a pivotal consideration for your equipment. Is there predictability in your fleet? Then maybe there is less variability in types of weather you encounter. But if there is any variability, it’s best to prepare for the unknown. MWS: WHAT IS WINTERIZATION FROM AN ENGINE OIL PERSPECTIVE?WHITACRE: One of the significant fundamental challenges Chevron has faced when we develop fluids is that we have to ensure that the fluids are functional across a wide temperature range, spanning from when the vehicle/equipment is off and stored in a cold location overnight, up to the temperatures that the fluid encounters inside a running engine and in a local environment that is hot. From that standpoint, the fluids are purposely developed to be functional across a very broad range of temperatures.For fleet owners, understanding an oil’s viscosity is essential to choosing the right engine oil for your fleet. Viscosity is the measure of the oil’s ability to flow. As temperatures drop, the oil becomes thicker and harder to pump, which makes it harder to start the engine. Chevron provides some oils that use a synthetic base, which tend to lend themselves to better low temperature operability. Oils such as 5W-30 and 5W-40 allow for a robustness to lower temperature operations. They provide as much as 5 to 10 degrees of better robustness to cold climates than the 15W-40 provides. MWS: HOW CAN A FLEET OWNER/OPERATOR ENSURE THEY ARE ADEQUATELY PREPARED FOR WINTER?WHITACRE: First, it’s critical to understand the two components of the viscosity grade. The first number represents the low temperature characteristics of the oil (this matters most when discussing winterization), and the second number represents the high temperature characteristics of the oil. A 15W oil is developed to be sufficiently fluid down to -20 to Is Your Fleet Ready for Winter?CHEVRON LUBRICANTS CAN HELP YOU PREPARE

AUGUST 2021 WWW.MWSMAG.COM MODERN WORKTRUCK SOLUTIONS 15-25 degrees C. As the number decreases, the oil can be used in even lower operating temperatures. For fleets in the most extreme temperatures, a 0W oil will get you down to -35 to -40 degrees C operating temperatures. Those conditions are more typical for northern parts of Canada. Fleet owners should choose a fluid that has the right viscosity grade for the environment where their vehicles and equipment will be operated. For example: A lot of heavy-duty engines recommend a 15W-40 viscosity grade. What we often see is that a customer will select an all-season product such as a 10W-30 that provides a little bit of robustness for operation year-round or maybe something like a 5W-40, such as Chevron’s Delo 400 XSP 5W-40, that provides strong low-temperature protection. MWS: WHAT SETS WINTERIZATION APART FROM ROUTINE MAINTENANCE AND INSPECTIONS?WHITACRE: Coolant. Most types of operation are fairly robust year-round, and that’s the case if you’re running the most typical water combination of 50/50. The biggest concern in terms of coolant protection and winterization is its freeze point. That’s the primary reason ethylene glycol is added to coolant—to lower the freeze point. A 50-50 mixture of water and glycol provides freeze protection down to -34 degrees F. If there are situations where you expect to encounter temperatures below that, a 60/40 glycol and water mixture might be more appropriate. It brings the freeze point protection down from -34 to -63 degrees F, but that’s only recommended when and if you’re going to encounter those extreme temperatures routinely throughout the winter. It’s not an ideal proportion in terms of the heat transfer characteristics of the coolant. Therefore, Chevron recommends you switch back to a 50/50 mixture in summer months.MWS: ARE THERE SOME CLIMATES WHERE 15W-30 IS GREAT YEAR-ROUND VS. CLIMATES THAT REQUIRE DIFFERENT OILS PER SEASON? WHITACRE: As long as vehicle and equipment is always in a climate above -20 degrees C then a 15W-40 is appropriate. A lot of on-highway fleets use 10W-30 because it provides a fuel economy advantage and more robustness in low temperature operations. That oil is great for a vast majority of the United States. It’s really during winter operation in northern climates that a 5W and 10W are more appropriate. It can also depend on how equipment is handled when not operational, whether stored indoors or always operational—even if just sitting idle. It depends on the particular application and the operating conditions to dictate what is most appropriate. Switching to winter-grade lubricant provides robustness to variability. That’s critical for a lot of trucks because it’s difficult to predict where the unit will go and how the weather will be when they get there.MWS: DOES CHEVRON OFFER ANY PRODUCTS SPECIFICALLY FOR USE IN COLD CLIMATES OR IN WINTER WEATHER?WHITACRE: As mentioned, the Chevron Delo 400 XSP is a full synthetic engine oil offered as 5W-30 or 5W-40. It offers good low temperature protection, and it is a good choice to tap into the performance benefits that full synthetic products bring. In addition to its full-synthetic base, Delo 400 XSP delivers value through minimized operating costs and robust wear control.Chevron is also learning more about the impact cold weather has on equipment—specifically the aftertreatment system. Emission control systems are typical in newer trucks. These devices require specific exhaust temperatures to function, and they can struggle during winter months. Certain components in the lube oil can interfere with the diesel particulate filter (DPF) because they are incombustible materials that can clog the DPF over time. To combat this issue, Chevron’s Delo 600 ADF (offered as a 10W-30 and 10W-40) features a lower level of materials that could clog the DPF. This low-ash oil keeps the filter clean, which presents fewer challenges the vehicle faces when trying to overcome the lower temperatures prevalent in the exhaust during winter months. MWS: ARE THERE ADDITIONAL CONSIDERATIONS FOR WINTER?WHITACRE: There are some other considerations with respect to winterization. Chevron suggests fleets talk to their fuel provider to make sure they’re using a fuel that is appropriate for their application. Sometimes there are winter additives that help with cold weather fluidity preventing the fuel from clogging fuel filters. It’s even more critical for fleets using a biodiesel blend because biodiesels tend not to be ideal fuels in winter climates unless additives are used properly and the fuel is used at the right blending conditions. Diesel exhaust fluid (DEF) also needs to be considered. Winter is a great time to check the function of onboard DEF heaters. Additionally, for general maintenance considerations, it’s a good idea to ensure all your fluid levels are topped off and that hoses are in good condition with no tears or leaks.FOR MORE INFORMATION Shawn Whitacre is a senior sta engineer at Chevron. Find out more, visit www.chevronlubricants.com.

MODERN WORKTRUCK SOLUTIONS WWW.MWSMAG.COM AUGUST 202116MEDIUM-DUTY WORKTRUCK SHOWCASEMEDIUM-DUTY WORKTRUCK SHOWCASEThe Peterbilt Model 535 & 536 ReviewA NEW GENERATION FOR ESSENTIAL DRIVERS By Jade Brasher

AUGUST 2021 WWW.MWSMAG.COM MODERN WORKTRUCK SOLUTIONS 17The Peterbilt Model 535 & 536 ReviewA NEW GENERATION FOR ESSENTIAL DRIVERS By Jade Brasher

Let’s face it. Our nation runs on the backs of vocational truck drivers. When the shutdowns happened last year, the truckers were deemed essential. Without those working in the utility segments, delivery, and even dump and garbage segments, our lives wouldn’t be the same.When you’re running an essential operation, it’s best to run it in trucks that you can count on. However, these trucks shouldn’t only be reliable. They should be capable enough to withstand anything the workday can throw at it, while also being economical to ensure your business makes a profit at the end of the day.When redesigning its medium-duty lineup, Peterbilt took great care in creating trucks that drivers would love to operate with features that owners couldn’t resist. I had an opportunity to get into the cabs of the Peterbilt Model 535 and 536 in the spring, and I’m here to report. From the capability of the trucks to their comfortable, practical perks, I have the feeling these medium-duty Peterbilts have what it takes to be a hit in the vocational segment.UNDER THE HOODA truck that’s used in essential operations should feature a powertrain that steps up to the challenge. Peterbilt’s PACCAR powertrain does just that. Under the hood of the Model 535 and 536, owners have the option of a PACCAR PX-7, PX-9, or CNG engine. The PACCAR PX-7 offers 200 to 360 hp. The PX-9 is for larger vocational jobs and offers up to 450 hp. Pairing the engine with PACCAR’s new TX-8 transmission offers more benefits.The new PACCAR TX-8 automatic transmission shifts the Model 535 and 536 into action. PACCAR built the new transmission to provide a best-in-class power to weight ratio and up to 5% fuel savings compared to other transmissions. Additionally, the TX-8 is designed to be the perfect complement to PACCAR’s PX engines in vocational applications. The lightweight, quiet-running TX-8 offers a maximum torque rating of 1,000 lb-ft and up to 57,000 lbs GCWR. And finally, your essential business meets reliable. Peterbilt designed the TX-8 to reduce the total cost of ownership with oil change intervals at 150,000 miles and fully encasing all sensors, wiring, and connections to minimize exposure to the elements. Now if only reliable were paired with comfortable…DRIVER PERKSDid someone ask for a comfortable cab? Peterbilt’s new medium-duty lineup features a cab that is 8-inches wider, so even if your operation calls for a bench seat to fit three people in the front, they’ll still have plenty of space. The cab height of the Model 535 and 536 is also 3 MODERN WORKTRUCK SOLUTIONS WWW.MWSMAG.COM AUGUST 202118MEDIUM-DUTY WORKTRUCK SHOWCASE

AUGUST 2021 WWW.MWSMAG.COM MODERN WORKTRUCK SOLUTIONS 19inches lower than previous models. This combined with anti-slip, stair-style steps and a knurled grab handle make it easier and safer for your drivers and crew to enter the cab.The cab also features 4.6 cu-ft of storage. Find that storage under the seat, in the door, overhead, and on top of the dash. There’s also access to the under seat storage from the side, which allows drivers and operators to grab what they need under the seat while standing outside the cab. There’s even a flat floor all the way across the cab to help keep it clean. And, you won’t have to worry about wear and tear on the truck’s pristine interior because textures and surfaces inside the truck are scratch resistant and don’t absorb odors. For the driver who works during all hours of the day, an interior pin light above the dash prevents drivers from having to turn on all interior lights to access their mug, thermos, or something else in the cup holder area. I personally love this feature because it keeps drivers’ eyes from having to adjust from nighttime darkness to bright interior lights and back. And we can’t talk about the new medium-duty lineup without mentioning the new instrument cluster with 7-inch high-resolution display. The display includes an analog speedometer and tachometer, but the 7-inch display shows drivers important information at a glance. Drivers can toggle through the menu using buttons on the steering wheel. The display is fully integrated with Peterbilt’s Advanced Driver Assistance System (ADAS).SAFETY IS ESSENTIALSpeaking of Peterbilt’s ADAS, let’s look at it a little more closely. Peterbilt offers the system in its medium-duty and heavy-duty lineup. The system uses advanced radar and camera technology to detect objects that could cross the truck’s path. The system, in conjunction with advanced software and powertrain integration, will then cause the truck to slow down or even stop to avoid a collision.Aside from the advanced technology creeping into every truck on the market, Peterbilt designed the cab itself with safety in mind. This includes larger windows for visibility, the lower cab, the stair-style steps, and grab handles previously mentioned.BEHIND THE WHEELWhen your business employs non-CDL holders, I believe it’s important to supply them with a truck that creates a seamless transition from the vehicle they drive to work and the vehicle they drive for work. Unless you train your drivers—which, you should—they might be overwhelmed at the task of driving a truck loaded with equipment. Thankfully, the Model 535 and 536 were easy to drive. The trucks’ maneuverability around tight curves and ability to get up to a comfortable speed relatively quickly was impressive. I drove a both trucks with unloaded box bodies of different sizes on the back, and even still, they handled well. At a time when employee and drivers shortages abound, perhaps the Model 535 and 536 is just the truck to keep your essential business running smoothly.ABOUT THE AUTHOR Jade Brasher is the editor of Modern WorkTruck Soluons magazine. A graduate of The University of Alabama, Jade resides in Kennesaw, Georgia, and enjoys wring about her town, travel, and of course, work trucks. Reach her at jade@mwsmag.com. Find out more about the Peterbilt Model 535 and 536 and the new medium-duty lineup, visit www.peterbilt.com.

LOOKS TOUGH. WORKS TOUGHERBED SLIDES FOR WORK TRUCKS, VANS, SERVICE BODIES AND TRAILERS• HEAVY DUTY – Up to 3,000 lb. load capacity • BUILT TOUGH – 20 year warranty• EXTENDS OVER 110% - past your taillights • FULLY CUSTOMIZABLECOVERED SERVICE BODY TELECOM TRUCK W/ SHELLEXTENDOWALL IN VAN-SIDE DOOR MOUNT PROMASTER VANRAM VAN STORAGE WITH PULLOUT WORK SURFACEWORK TRUCK WEEK 2021 SHOW DISCOUNT EXTENDEDCall or email now to get a complimentary design and quote800-752-0706websales@extendobed.com • www.extendobed.com

MODERN WORKTRUCK SOLUTIONS WWW.MWSMAG.COM AUGUST 202120OPERATIONSHow to Prepare for a Trouble-free Snowplow SeasonFROM YOUR SALT SPREADER TO YOUR SUSPENSION

AUGUST 2021 WWW.MWSMAG.COM MODERN WORKTRUCK SOLUTIONS 21Trouble-free snowplowing begins with using the best snow equipment on the market. Choosing the best truck, the best tires, and the best snowplow equipment will make a huge difference for the newbie just entering the commercial snow-removal arena.HEAVY-DUTY PICKUPSIf you’re planning to do some serious plowing, you will need to get a vehicle that can perform well in all types of snow. But if you’re like most others who plow commercially, the large snowplow trucks require too big an investment. So, what are your next best options? You might consider full-size pickup trucks with four-wheel drive. The five favorite HD models in North America are:1. Dodge Ram 2500 and 3500. These are available with a factory- installed snowplow prep package.2. Ford F-250 and F-350. These are also available with a factory-installed snowplow prep package.3. Toyota Tundra. Although technically a half-ton, this truck is still a popular choice.4. Nissan Titan XD. This truck can be used with most plows available on today’s market.When considering which is best, the most rugged pickups have a straight axle on the front suspension. Trucks that come with independent suspension offer a great ride, but aren’t nearly as rugged. WINTER TIRESWhen it comes to winter tires, there are several to choose from. See the breakdown of popular winter tires below:Cooper Tires Discoverer M+S• Tire Type: Winter Tire “Beyond its deep tread, the Discoverer M+S features strategically placed stud pinholes and a sawtooth center rib and a supple rubber for good traction on snow.” Bridgestone Blizzak• Tire Type: Winter Tire “The Blizzak tread has ‘3-D Siping’ as well as a ‘multi-Z pattern’ in the center of the tread, which allows for increased drainage from melted snow and ice—further improving traction in wintery conditions.” Firestone Winterforce 2• Tire Type: Winter Tire “The Winterforce 2’s tread is full depth with open shoulder slots,

MODERN WORKTRUCK SOLUTIONS WWW.MWSMAG.COM AUGUST 202122OPERATIONSso the tire easily finds grip in slick conditions making easy work of moving melted snow.”Nitto Terra Grappler G2• Tire Type: All-terrain Tire “While the G2 is an all-terrain tire, it’s one of those rare tires that manages to balance tread durability with the suppleness needed for extra grip on snowy terrain.”BFGoodrich All-Terrain T/A KO2• Tire Type: All-terrain Tire “While the KO2 is not a dedicated winter tire, it is rated as three-peak mountain snowflake (3PMSF), which simply means the tire is rated for optimal performance in severe winter weather.”SNOWPLOW TYPESThere are two types of snowplows: the V-plow and the straight blade. A straight-blade plow is more economical than a V-plow but not as easy to maneuver. A V-plow has various functions giving it more options for better use. For example, when the plow is in its V formation, it can easily cut through ice and hard-packed snow. Obviously, the best plow for commercial use is the V-plow. Just make sure that your pickup can handle the weight of the plow; 8-ft plows can weigh up to 1,000 lbs. If your pickup squats when you lift the plow, there are ways you can solve this problem.TAILGATE SALT SPREADERIf you’re just starting out, it’s unlikely that you’ll invest in a big flatbed truck with a huge tank of salt solution on the back. But it’s important that you invest in something. Here is a short list of some of the best tailgate salt spreaders available:1. Meyer Mate XL 2. Meyer Baseline3. SnowEx Salt spreaders can make your job of snow removal so much easier by preventing any dangerous buildup of ice during freezing-rain conditions. HELPER SPRING With or without a snowplow prep package, you’re going to need some type of suspension spring helper. Over time, the weight of a plow—not to mention the weight of a heavy snowfall—will take its toll on your front suspension. To prevent damage and extend the life of your front suspension, you’d be wise to install helper springs sooner rather than later.Taking care of front-end squat will also improve tire traction at the back end. Of course, adding a salt spreader will also increase traction, but will add stress to the rear suspension. Fortunately, there are helper springs available for both front and rear.Here is a list of the different spring assists available:• Steel helpers There are basically two types of steel helpers that either bolt on or clip to the existing leaf springs.

AUGUST 2021 WWW.MWSMAG.COM MODERN WORKTRUCK SOLUTIONS 23Both are easy to install but come with a limited warranty. • Coil assist Coil Design Helper Springs are designed to work together with a leaf spring setup. They mount to the U-bolts in the center of the leaf spring and attach to the frame above. Unfortunately, they’re not strong enough to assist a plow truck. • Air bag assist Airbags were originally used as an alternative suspension to leaf springs. More recently, they have been designed as a load-leveling helper spring. However, they are somewhat vulnerable to corrosion caused by sand and salt and are unable to stabilize heavy loads. • Rubber helper springs Timbren SES (Suspension Enhancement System) kits use Aeon® hollow rubber springs made from natural rubber that are designed to easily replace the bump stops on trucks, vans, and SUVs. These hollow rubber springs have the ability to: • completely level the load by eliminating any sag and squat • increase stability by reducing roll and sway • smooth out the ride by cushioning road shock • easily replace the factory bump stopsThese easy-to-install kits come with a lifetime warranty and a customer satisfaction guarantee.BE PREPAREDIt’s important to invest in the best equipment that you can afford. If you haven’t, there’s still time. As a commercial snow-removal expert, you should know the pitfalls of cutting corners and taking shortcuts. Be the business that is in it to win it. And don’t forget. Just because you spent a ton of money on the truck, the plow, and the hopper doesn’t mean you’re fully prepared. You still need to pay attention to your truck’s suspension. After all, the suspension is the foundation of your growing enterprise!It’s no secret that the hollow rubber springs in a Timbren SES product will give you the best combination of strength, stability, and ride quality. Timbren SES will better prepare you for a trouble-free snowplow season!FOR MORE INFORMATION Find out more, visit www.mbren.com. JANUARY 2021WWW.MWSMAG.COMLIGHT-DUTY SHOWCASE: FORD F-250 TREMOR REVIEW FOR WORK AND PLAYCONCRETE INDUSTRY TELEMATICSINVEST IN KNOWLEDGE THE TELEMATICS AND FLEET MANAGEMENT ISSUETHESEAMLESS TELEMATICS SYSTEMSSMART SOLUTIONS FOR FLEETS COVERING ALL THINGS WORK TRUCK - FOR ALL TRUCK CLASSESWWW.MWSMAG.COMWWW.MWSMAG.COMTHAT’S 60+ ISSUES OF MONTHLY MUSCLE You’re welcome!CELEBRATING A MILESTONECELEBRATING A MILESTONE

MODERN WORKTRUCK SOLUTIONS WWW.MWSMAG.COM AUGUST 202124OPERATIONSWeather, infrastructure, capacity, and labor needs change region to region, and as a result, the plows that contractors choose must adjust to meet their regional needs. With so many options available, better understanding the role each front-mounted plow type plays in protecting streets and pedestrians can help you make more informed decisions in your investments. The experts at Monroe Truck Equipment have put together a guide to assist contractors in their decision-making process. PLOW CONSIDERATIONSThere are several reasons why a snowplow that works really well for one region may not work for yours. When considering buying a snowplow, one of the biggest considerations to factor in is the location and infrastructure of your area. 1. Regional needsDo you work in rural areas with expansive properties? Do you work in a densely populated metropolitan area where you have to consider parked cars, pedestrians, trash bins, and other objects that get in your way? Or perhaps you need a plow for a residential or medical campus, hospital, cemetery, or other contained spaces. This will be one of the biggest aspects to consider when investing in a new plow. 2. Truck limitationsA major factor to consider that impacts your investment is the weight and size of the complete plow and how it works with your vehicle. Plows can start at widths as small as 6.5 ft for small pickups and go all the way up to 12 ft or more for the largest truck applications. When choosing the size of the plow, the Gross Vehicle Weight Rating (GVWR) and Front Gross Axle Weight (GAWR) are important to ensure your safety. If you continually use a plow that is too heavy for your truck, it can stress the front axle and suspension and worsen the efficiency of your braking system.3. Identifying the best plowsThere are a lot of options when it comes to snowplows. Different manufacturers have different designs and features that create a variety of options for the purchaser to make. However, most front-mounted plow designs are iterations of two core plow products: straight blades and V-plows. Understanding which plow type is foundational. Then you can choose additional features like wings and underbody scrapers that will further enhance your plowing capabilities.TYPES OF PLOWSStraight plows are a good general purpose plow choice for large, expansive spaces like parking lots, airports, and off road plowing. Alternatively, they are also a good choice on a smaller scale for driveways Choosing the Right PlowTIPS FROM MONROE TRUCK EQUIPMENT By Jim Smith

AUGUST 2021 WWW.MWSMAG.COM MODERN WORKTRUCK SOLUTIONS 25and small properties. They are general purpose because they are simple to operate and are mounted directly on the front of the truck to push and drag snow. Unfortunately they do not work for all situations, snow types, and infrastructure types. V-plows are a great, versatile option because they’re more dynamically designed and can handle a larger variety of tasks. V-plows can break into a snowbank in areas of heavy and accumulated snow. They can also “scoop” snow in the V-formation, which is extremely useful when plowing areas such as between rows of parked cars and other obstacles. The scoop position also allows snow to be stacked much higher than straight blade applications. USING YOUR PLOWOnce you know what type of blade and model of snowplow that will work best for your job, you can start making decisions about the additions and upfitting options that will make your job easier, help keep you comfortable, and move with ease. Salt spreaders are incredibly important additions to a snowplow, and there are several options available. Again, consider where and how you work. In addition to spreaders, you may want to consider features like additional lighting, back-up alarms, additional steps for getting in and out of the cab, or storage options for any additional snow and ice equipment or tools you may need. OTHER CONSIDERTIONSThere are plenty of features to consider and options to weigh when investing in a new plow. Material type, hydraulic options, manufacturer, mount and operating systems, and much more. A foundational understanding of what type of front-mounted plow will work best for your region and your truck will give you the space to explore the smaller specific options that will make sure your plow works best for your work style and business goals.CONSIDER A PARTNERSHIPIn addition to investing in a plow that meets the needs of your region and the features that help you work best, consider making an investment with a dealership or manufacturer where you can build a trusted relationship with a representative. Even after a sale, it’s important to have someone you can go to for training, advice, questions, or any concerns you may have.ABOUT THE AUTHORJim Smith works for Monroe Truck Equipment. Find out more, visit www.monroetruck.com.

MODERN WORKTRUCK SOLUTIONS WWW.MWSMAG.COM AUGUST 202126MAINTENANCEDiesel is an organic compound, and like a slice of bread, it can go moldy. Mold, a form of fungus, yeasts, and bacteria can grow in fuel over time. Termed “microbiological contamination,” this threat is greater now as the global pandemic has created a reduction in fuel turnover. As fuel is stored and backed up in the supply chain for longer, road haulage and commercial forecourt operations need to take extra care to keep this contamination in check.While consuming moldy bread may not be an appealing option, it will not actually do you any harm. Microbiological contamination in fuel supplies on the other hand has much more serious consequences on fuel systems and storage tanks. As microbes multiply in the fuel, they can form a biomass layer consisting of billions of organisms. This biomass can block filters, increase injector wear, and even corrode tanks with the organic acid it produces. Worst of all, microbiological contamination can be passed along the fuel supply chain, whether from pipeline to storage tank or fueling truck to retail Testing for Fuel ContaminationARE YOU BEING BUGGED? By David Armitageheavy-duty feature

AUGUST 2021 WWW.MWSMAG.COM MODERN WORKTRUCK SOLUTIONS 27forecourt. This means that even if a depot experiences high fuel turnover delivering food, Amazon boxes, or other supplies, the overall slump in global fuel consumption across all modes of transport means contamination from the fuel supply chain could still be an issue.Rachel Harrison at Fueltek Ltd, says, “The ‘diesel bug’ is something that anyone storing fuel in bulk is generally aware of, but maybe not of the increasing risks it poses.”HOW IT OCCURSWhat does this mean for maintenance techs and depot managers? No one wants to add unnecessary activity or cost to operations, but managers need a way to make smart decisions to help prevent the potential of significant remedial costs due to damage caused by microbiological contamination. But why does microbiological contamination occur?Fuel inherently contains water in some form as soon as it leaves the sterile environment of the refinery. Water can be picked up at any point in the supply chain in pipelines, storage tanks, and fueling trucks. It can also naturally enter storage tanks due to condensation, making it impossible to keep it completely out of the supply chain. Of course, many companies have sophisticated wet stock management with water sensory equipment, but even the smallest amount of water (far from the levels these mechanisms can detect) can do damage. Couple the presence of even a small amount of water with the use of more sustainable and environmentally friendly fuels, which has led to a reduction in sulphur and addition of biofuels, and the microbiological problem gets worse. While steps can be taken, such as cleaning fuel tanks or dosing them with biocides if the tank is not contaminated, this adds a significant cost to operations. A regular, on-site testing regime using lateral flow devices, however, offers a quick, easy, and low-cost way to ascertain whether action needs to be taken. ON-SITE TESTINGImmunoassay antibody test kits, such as FUELSTAT® from Conidia Bioscience, are a proven technology to give accurate levels of microorganism activity in a fuel source. Testing can be carried out on-site without the need for in-depth training or investment in sophisticated test readers or other high-tech equipment. The kits require no special handling, storage, or disposal and are safe and easy to use, providing quick results without the need to send samples away for testing. The very nature of how the test works means that there is minimal risk of cross-contamination (unlike if samples are sent away to a lab), results are accurate and completely reliable, and site managers can take control in ensuring they will not be caught with undetected contamination.Compared with other testing methods or technology to prevent a buildup of microbes, antibody test kits are one of the lowest cost options. With no initial capital investment required, the cost of a kit provides an almost immediate return on investment if it prevents just one unnecessary storage tank clean or biocide dosing or averts an incident where an engine is damaged by the microbiological contamination.Antibody fuel test kits have been used for many years in the aviation industry where fuel testing has long been a standard procedure, and other bulk users of diesel fuels, such as marine and power generation have followed suit. Most people are aware of the technology, which is widely used in the medical industry, as it is the principal test for the COVID-19 infection. While there is no regulation or mandate to test fuel supplies at garage forecourts or at road haulage refueling hubs, the risks contamination poses—especially at a time when overall throughput in the supply chain is lower—are significant.A TESTING REGIMEMicrobiological contamination can occur at any stage in the fuel supply chain. In any testing process, some important procedures should be followed: Sampling points should be wiped clean with at least 70% alcohol solution or wipe; sampling equipment should be cleaned after each sample

MODERN WORKTRUCK SOLUTIONS WWW.MWSMAG.COM AUGUST 202128MAINTENANCEis taken; and ideally, a new sampling container should be used for each sample.If a site begins to use antibody test kits to periodically test fuel supplies, the frequency of this testing can be adjusted as historical results are catalogued. If using FUELSTAT® test kits, site managers will have the added benefit of a free result app, which can be installed on both iOS and Android mobile devices. Users scan the test kit and get instant digital verification of the test results that they can store and share. Managers have access to the report portal to track test results across all their assets in real time. For companies that employ fuel maintenance contractors, fuel testing is not assured, and the number of cases in the road transport sector of equipment being damaged because of contaminated fuel is increasing. “A regime of good fuel husbandry and management should be in place,” Harrison says. “And antibody test kits are a useful, inexpensive tool to support this. We have used the antibody testing kits extensively to satisfy our customers’ demands to ensure they are using clean, uncontaminated fuel. They have proved reliable and successful and have added another income stream to our organization.”REDUCE RISKSIf left unchecked, microbiological contamination can have serious impact on machinery and drivers. Indeed, the damage it can cause to diesel engines, fuel tanks, pumps, and other machinery should not be underestimated. The contamination can be transferred to most middle distillate fuels and will grow if left undetected. Water is the fuel’s worst enemy, and it is good practice to periodically remove as much water as possible from supplies. But testing is the only way to be sure that contamination is not left unchecked and machinery is not damaged. This testing can be carried out by a single person and does not need to be an onerous or expensive task.Antibody test kits offer a simple, quick, cost-effective way of checking fuel supplies on-site without the need for specialized skills or procedures. For facility or fleet managers, these kits could lower maintenance costs and reduce risks to day-to-day operations. For all drivers, the cost of avoiding catastrophic engine failure on our highways certainly goes way beyond the cost of a lateral flow test kit.ABOUT THE AUTHORDavid Armitage is the head of business development at Conidia Bioscience. Find out more, visit www.conidia.com.

How to Encourage Drivers to Keep Tires InflatedEDUCATE, INCENTIVIZE, COMMUNICATE By Mike Skoropad MODERN WORKTRUCK SOLUTIONS WWW.MWSMAG.COM AUGUST 202130MAINTENANCEA recent study by Continental Tires found that 34% of fleet drivers regularly ride on underinflated tires. Aside from reducing traction and increasing braking distances, driving on underinflated tires can decrease your fleet’s fuel economy. The NHTSA has found that every 1% that a tire is below its recommended inflation level, gas mileage is reduced by 0.3%.In short, whenever a fleet driver rides on underinflated tires they are both increasing their own risk of accident and pushing up a company’s operating costs. It should therefore be a priority for any fleet company to try and reduce the number of miles driven on underinflated tires.DRIVER EDUCATIONContinental’s study into fleet drivers’ behavior revealed the worrying statistic that 17% of drivers do not know how to check their tire pressure. Although fleet managers may try to explain away this fact by pointing toward the fact that modern trucks come with tire pressure monitoring systems, these only alert a driver when tire pressure falls below 25% the recommended level. If you want to maximize fuel economy, then drops in pressure need to be noticed and rectified before this stage.Getting this right starts with driver education. For many fleets responsibility for safety and maintenance of vehicles falls with fleet managers and technicians. This neglects the fact that it's only drivers who work with vehicles day in and day out that can truly implement preventive maintenance like keeping tires optimally inflated.The following skills should be taught to drivers during their fleet training:• How to check tire pressure.• Staying conscious of which gas stations have tire pump services.• How to visually diagnose early signs of tire damage.• How to inflate your own tires in case of emergency.

AUGUST 2021 WWW.MWSMAG.COM MODERN WORKTRUCK SOLUTIONS 31Drivers should also understand the reasons why keeping their tires inflated is so important so they have the motivation to implement tire maintenance.INCENTIVESSince one of the biggest reasons why fleet operators want their drivers to be diligent in keeping their tires at the recommended inflation are the fuel savings that it will create, operators have the margin to offer incentives to drivers to ensure this happens.Operators have a couple of ways to incentivize drivers to keep their tires inflated. These include:• Offering incentives around fuel consumption. Tire inflatedness is one of the biggest determinates around a vehicle’s fuel consumption along with driving technique. Offering bonuses around achieving a certain mile per gallon (or below) can therefore directly reward drivers who diligently maintain their tire inflation. • Offering incentives around regular tire pressure checks. Drivers can be rewarded specifically for checking and maintaining their tire pressure. To do this, you just need to make your drivers fill out a logbook once every two weeks with their measured tire pressure and (crucially) photos of their tire pressure gauge readings. Reward your drivers for keeping this logbook full every quarter.Since fuel costs account for around 60% of a fleet’s total operating costs, offering your drivers a small bonus to keep their tires fully inflated should pay itself back in spades over time.CHECKS & COMMUNICATIONAs well as incentivizing drivers with rewards for keeping their tires inflated, fleet operators can also keep drivers accountable by putting in place a system of spot checks to ensure that tire maintenance is performed regularly.Your technicians and maintenance team are a great place to start with these spot checks. Signs of long-term tire underinflation can be easily diagnosed visually by technicians with tire side wear being the clearest indicator of this. If one of your vehicle technicians spots tire side wear, then this should be a reason to remind the driver about the importance of keeping their tires inflated. If this happens more than once, then this could be a sign that the driver needs training.Spot checks can also be performed by fleet managers at common stops on drivers’ routes. These checks can include checks on the tire pressure itself, as well as checks that a driver has a tire pressure gauge in their possession. Penalties should be given to those who regularly fail these inspections.ABOUT THE AUTHORMike Skoropad is the owner and head technician at re retailer United Tires. Find out more, visit www.ures.com.COVERING ALL THINGS WORK TRUCK - FOR ALL TRUCK CLASSESWWW.MWSMAG.COMWWW.MWSMAG.COMTHAT’S 60+ ISSUES OF MONTHLY MUSCLE You’re welcome!CELEBRATING A MILESTONECELEBRATING A MILESTONEJUNE 2019www.mws mag.comBottom Line SavingS5 TrEN ds To Imp lEmENTmEdIUm-dUTYpETErBIlT modEl 337hEavY-dUTY MACK PINNA CLElIghT-dUTYNISS AN TITAN XDPRoPeR HanDLingorga NIzINg Yo Ur oIlStRongeR tHan SteeLrUBBE r sprINg s arE ToU ghDiStRacteD DRiving a Fo rgoTTEN daNgE rJaNUarY 2021www.mws mag.comLIGH T-DUTY S HOWCASE : FORD F-250 TREMO R REVIE W FOR WORK AN D PLAYconcRete inDUStRY teLematicSINvE sT IN KNo wlEdgE tHe teLematicS anD FLeet management iSSUetHeSeamLeSS teLematicS SYStemSsmarT solUTIo Ns For FlEETsJULY 2016lIghT-dUTYmErcEdEs-BENz sprINTEr mEdIUm-dUTYINTErNaTIoNal TErrasTarhEavY-dUTY pETErBIlT 567PoWeR oF cHoice cUmm INs wor K TrUcK ENgI NEs Fo r 2017PoWeR oF cHoice cUmm INs wor K TrUcK ENgI NEs Fo r 2017KeePing YoUR FiLteR in oRDeR dpF maINTE NaNcE aNd s ErvIcINgKEYs To FINdI Ng ThE r IghT oNEFLeet management SoLUtionBacKUP PoWeR UlTraca pac ITors doN’ T rEpl acE BaTTErI EsFLeet management SoLUtionKEYs To FINdI Ng ThE r IghT oNE

MODERN WORKTRUCK SOLUTIONS WWW.MWSMAG.COM AUGUST 202132MAINTENANCEMost regions of the country are more than familiar and prepared for severe weather conditions at some point throughout the winter months. However, even if a region can predict its winter storm season or is caught by surprise, like much of Texas earlier this year, it is imperative for fleets to practice general preparedness for operating and maintaining work trucks during subzero weather. A combination of performing pre-and post-trip inspections, conducting regular maintenance checks on equipment, and following safety precautions will help fleet managers keep equipment up and running, drivers safe on the roads, and worksites operating in compliance with OSHA winter weather standards at worksites. WINTER MAINTENANCE Maintaining equipment in subzero weather conditions is half the battle, and it begins with validating the operating status of equipment. Ensuring that equipment is up to date, serviced regularly, and functioning properly is easily achieved through electronic verified inspection reporting (EVIR). For example, cables and wires are prone to freezing in subzero weather. During the pre-trip inspections, it is important to take the time to manually remove snow buildup and unthaw frozen wires or cables before operating the vehicle. Another important component of work trucks that are impacted by subzero weather conditions are fluid levels, which require regular checks and monitoring. Consider these three winter maintenance best practices:• Overcome maintenance yard inaccessibility with over-the-air updates. Some fleets turn to technology to maintain equipment in subzero weather when vehicles stored in maintenance yards are inaccessible. Over-the-air updates through connected software to the Engine Control Module (ECM) assures vehicle engines are updated even when weather limits access to manual maintenance. • Employ automated advisories for hours of service (HOS). Automated advisories are another technology tool that keep fleets operating in subzero weather. Advisories can help drivers plan routes ahead of time to avoid storms or allot extra time for Operating and Maintaining Work Trucks in Subzero Weather TIPS FOR A SAFE AND COMPLIANT FLEET By Fred Fakkema

AUGUST 2021 WWW.MWSMAG.COM MODERN WORKTRUCK SOLUTIONS 33trips through inclement weather. Automated advisory tools equip drivers with additional resources such as access to view area traffic cameras or quick reference for the 5-1-1 transportation and traffic information telephone hotline. • Weatherproof hardware. Just as extreme heat can cause mobile hardware and tablets to malfunction, technology can also go down in cold weather. Installing designated charging stations to keep devices powered and maintained at operating temperatures ensures a fleet’s on-board technology doesn’t interfere with operations in subzero weather. SAFETY MINDSETAs I mentioned, maintenance is half the battle, but it is also imperative for fleets to employ a winter safety mindset. When you think about the challenges of cold weather, the first thing that comes to mind is visibility and determining the exact conditions of the road. Here's what to look for on the road to assess conditions: • Paying attention to other vehicles on the road. Be aware of and monitor the tires of the other vehiCles on the road. In subzero conditions, if there is no debris flying off the tires of other vehicles, it indicates the road might be slick, possibly with black ice. This clue tells a driver they should travel at slower speeds. Conversely, if debris is flying off of tires, the road is wet and still has traction. • Shift into neutral instead of slamming the breaks. In the event of an emergency stop in icy conditions, instead of slamming the breaks, which will cause the torque of the vehicle to carry forward, drivers should put the vehicle in neutral to decrease traveling speed. COMPLIANCE & SAFETYIn the enforcement world, the seemingly obvious challenges can lead to violations for fleets. Visibility is one important aspect that enforcement looks at to see if windshields are clear of debris such as snow, ice, and mud, which can blow off in transit and damage other vehicles on the road. A few states have laws that require snow to be removed from the top of the vehicle, including trailers, to prevent danger on the road. Functioning tires, mud flaps, lights, and windshield wipers are other maintenance flaws that law enforcement pays close attention to during the winter season. Consistent and thorough pre-and post-trip inspections are the best tool for fleets to maintain accessory equipment in subzero weather. Another important aspect of winter maintenance is outfitting your workforce with adequate gear that adheres to OSHA standards for worksite safety. PPE, including a safety and first aid kit, gear, and the right-fitting shoes and gloves will help workers perform better in the field and avoid accidents.Preparedness for driving on roads during extreme winter weather conditions can never be understated. Many states across the country have mandatory requirements for tire chains, especially when traveling through mountain passes. In winter, when weather conditions can turn quickly, it is imperative fleets are equipped with appropriate winter equipment and safety mindset for operating in subzero weather. ABOUT THE AUTHOR Fred Fakkema is the vice president of safety and compliance at Zonar. Find out more, visit www.zonarsystems.com.

MODERN WORKTRUCK SOLUTIONS WWW.MWSMAG.COM AUGUST 202134TECHNOLOGYFleet management is a complex business. As the largest pure-play fleet manager in the world, Element Fleet Management handles almost everything for its clients: vehicle purchasing and acquisition, maintenance, fuel management, vehicle financing and scheduling, and on-road compliance. Element has over one million vehicles on the road at any one time, so providing great client service means being safe, smart, and productive—and never dropping the ball. As the only publicly traded fleet manager in North America, Element has a responsibility to its investors as well.Recently, in pursuit of both superior client and employee experiences and increased revenue, Element’s executive leadership launched a business transformation program that promised to deliver $144 million of run-rate profit improvement in 2 1/2 years. Hitting the target meant unlocking better ways of working. And that meant automation. But how do you affect change across such a large, complex organization in such a short span of time? The answer is to partner well, start small, harvest and trust your team’s ideas, and devise a future-focused plan. STARTING SMALLEven in high-performing businesses, there’s likely to be low-hanging fruit. Element is no different on this score. Over the last seven years, Element acquired and integrated several fleet management providers, leading to inconsistent systems and processes. To compensate for these inconsistencies, Element relied on its employees to perform repetitive, high-volume, manual work, which was frustrating for them and inefficient too.Element already had some experience with robotic process automation with two dozen bots operating on the Automation Anywhere platform. But the version of the software Element used was becoming obsolete. And Element needed help to migrate and improve the bots. So, the company turned to Genpact, a global professional services firm that makes business transformation real and an Automation Anywhere Platinum Partner with a strong track record of helping companies across a variety of high-value industries, such as banking and capital markets, make new automation breakthroughs faster.PARTNERING WELLGenpact immediately began migrating the existing bots to the new software platform. Two weeks before the Fueling Business TransformationHOW EVEN THE MOST COMPLEX FLEET MANAGEMENT AND LEASING BUSINESS CAN AUTOMATE AT SPEED AND SCALE By Daniel Shardt and Venkatachalam NarayananFor fleet management, automation holds the key to better ways of working.

AUGUST 2021 WWW.MWSMAG.COM MODERN WORKTRUCK SOLUTIONS 35migration deadline, the job was done. Genpact started enhancing each bot with new features and supporting them to maintain 100% uptime. Quick win complete.Along the way, Genpact offered some advice. If Element wanted automation to make a more substantial contribution to its transformation goal, then a “lift-and-shift” for a handful of bots wasn’t going to cut it. For Element to deliver a consistent, superior end-to-end client and lease experience, they’d need a management-supported, enterprise-level automation drive. This would include high-level orchestration, standardized and centralized processes for automation, and a scalable operating model.HARNESS CREATIVITYElement didn’t need much convincing. Element asked Genpact to run automation roadshows to tap the expertise and creativity of employees in their service lines. Plenty came forward with their bugbears and bottlenecks, offering a more complete picture of what the company could solve with further automation. Together, Element and Genpact designed an automation roadmap that fit the company’s strategic objectives. Genpact then began to develop new bots at five times the rate of the original effort. These bots would automate individual processes at key stages of the leasing process, such as collections, and in other high-friction areas of the business too, such as claims management, registrations, human resources, and telematics. For example, one bot would schedule the delivery of preventive maintenance notices to Element clients and their drivers so fewer vehicles would ever see a breakdown. But true transformation is never going to happen on a bot-by-bot basis. So together with Genpact, Element decided to build an automation center of excellence with one team, one process, and one methodology to govern all automation efforts at speed and scale and help educate the organization as well. NEW HORIZONSThe engagement yielded improvement in every area it targeted. In just nine months, the bots processed over 1.3 million transactions, sparing Element employees 44,000 hours of work. Some of the bots also delivered new net revenue to the business—for example, speeding up the client onboarding process for a new service that helps Element clients manage toll payments and ticket processing. As a result, Element clients are 33% more satisfied now, and Element exceeded its $144 Million run-rate profit improvement goal. For fleet management and leasing businesses, automation holds the key to better ways of working. Now, Element is looking to add dynamic workflows that allow bots and humans to work together harmoniously and explore the possibilities of intelligent automation, such as conversational artificial intelligence to chat with clients.If you’re looking to automate across your leasing business, consider the following. First, go for the low-hanging fruit. Find some simple, quick-win areas to automate that can showcase to leadership and staff the power of digital solutions. Second, if you need to (and you probably do), partner up, and partner well. Find someone who is aligned to your vision and who provides solutions that reflect where you want to go. Third, ask your staff where their pain points are, and listen to them—they likely know best. And fourth, don’t just focus on today; roll out automation solutions that can be scaled up for the business you want to be tomorrow and in five years.ABOUT THE AUTHORS Daniel Shardt is the vice president of operaonal excellence and asset remarkeng at Element Fleet Management. Venkatachalam Narayanan is the global commercial banking and credit risk leader at Genpact. Find out more, visit www.elemenleet.com and www.genpact.com.

MODERN WORKTRUCK SOLUTIONS WWW.MWSMAG.COM AUGUST 202136TECHNOLOGYA simple principle generally causes bottlenecks and congestion: The roads and interchanges located in the worst spots are either poorly designed given traffic volumes or simply need more lanes. Unfortunately, the solution can be worse than the problem. Highway or road redesigns and new construction can sometimes cause bottlenecks, according to American Transportation Research Institute (ATRI). ATRI estimates that the trucking industry lost $75 billion in 2018 due to congestion and traffic jams. This translates to over 400,000 commercial truck drivers sitting idle for a year, per the report last conducted in 2018 by ATRI. While fighting traffic congestion is bad for long-haul truckers, it is especially bad for short-haul truckers who are contracted to only do one day of work or have regularly scheduled Fighting Traffic and CongestionEMPLOY SMART TRIP PLANNING By Robert Ramirez

AUGUST 2021 WWW.MWSMAG.COM MODERN WORKTRUCK SOLUTIONS 37trips planned each week. Short haulers are mostly day trippers who return home each night. They typically follow the same or similar route each day or travel only short distances of about 150 miles from their home base routinely. Running in this smaller area, the truck drivers become very familiar with the roads and know if there isn’t a work around a bottleneck. Long-haul truckers are dispatched to deliveries that can keep them on the road for weeks at a time. The drivers follow detailed plans of routes not restricted by the 150-mile border, so they can find a work around if there is an issue like congestion by simply going in another direction and using a different highway. Short haulers know where bottlenecks and congestion occur, but they may not be able to change their route or find a go-around because of the contained area of their restricted route. TIPS TO FIGHT TRAFFICAs post-pandemic travel gears up and roads jam, consider incorporating the following steps as a defense against losing money while stuck in congestion or being late with freight:• Trust your drivers' knowledge and experience. While technology is a valuable tool, you'll do best when using it combined with drivers' wealth of information about when lanes will be congested and when known bottlenecks will materialize. • Work with shippers and receivers on parking and drop trailers. You can ask customers to allow you to park overnight on their lots so your drivers don't have to time their arrival while fighting traffic. By getting there early, drivers can park, rest, and have the freight unloaded in the morning. You can also negotiate a drop-and-hook strategy with shippers so your drivers can drop off shipments and pick up a new load at a time that works for them. • Rely on on-the-ground data for rerouting. Using data from state departments of transportation, GPS sources, and the drivers themselves, you'll be able to communicate in real time with drivers about traffic. You'll also want to use a TMS that offers transportation planning, taking data from a trip where the driver encountered congestion at a particular time and incorporating that knowledge into planning future trips.To better manage predictability around drivers, it also helps to run transportation scenarios with a TMS factoring loads, origins/destinations, hours-of-service (HOS) requirements, and real-world ETAs. This approach lets you develop a step-by-step plan defining where they need to go for their pickups and deliveries and enabling them to stay compliant with their HOS requirements. SMART PLANNINGSmart plans begin with historical data collected within a TMS from telematics devices, GPS, and ELDs. This equipment monitors miles traveled, starts/stops, idling time, speed, and truck locations. Dispatchers and drivers use this information to build trip plans in their TMS that are realistic and profitable. Using post trip data, dispatchers can build the best route incorporating optional routes when congestion, traffic, school zones, or construction crop up. Pre-trip inspection time, driving time, required break time, and off-duty time can be factored into the trip schedule for even more accuracy. These accurate trip plans for drivers meet hours of service restrictions and provide more accurate estimated time of arrival (ETA). A transportation management system will generate an hour-by-hour plan for the driver considering their available work hours, pickup and delivery time windows, travel times, fuel stops, rest stops, and weigh stations. As each driver moves on the road, the trip plan and estimated arrival time are automatically updated. Smart trip plans should also factor in loading and unloading times. Often when delivering to a location, the truck driver may have to wait to unload the truck because there isn’t a dock door open, there is a long line of other trucks ahead of them waiting to unload, or there aren’t enough workers to help unload the cargo. To eliminate this issue, drivers or dispatchers should use a scheduling-type app or functionality within a TMS to arrange for a dock to be open, find times when there is less congestion

MODERN WORKTRUCK SOLUTIONS WWW.MWSMAG.COM AUGUST 202138TECHNOLOGYin the yard, and to schedule extra helpers to unload the truck. TELEMATICS & ELDsMany short-haul truckers don’t have to keep logs of their trips provided they stay within their hours of service restrictions of a 150-mile driving radius and limit of 14 hours on-duty time. So, few of these truckers have any ELDs, telematics, and GPS equipment installed in their trucks. Yet these devices provide additional benefits to the day hauler. Dispatchers have the ability to track trucks and monitor their travel. If a known road outage or planned event is going to occur, the dispatcher can alert the driver to the obstacle, then provide drivers with turn-by-turn directions to avoid it. Even though short-haul drivers are exempt from the ELD mandate, they are still required to keep accurate records of their hours of service and to monitor compliance with the 150-mile radius. The best and easiest way to do this is with an ELD device. Plus, ELDs and telematics equipment generate mounds of data that can be used for: • Protecting drivers from traffic accident liabilities because driver behavior is recorded and can be used as evidence to exonerate evidence.• Keeping in compliance with HOS.• Monitoring vehicle and engine diagnostics codes for improved maintenance and upkeep.• Avoiding having to keep paper records and tracking of the daily record of duty status.• Keeping track of truck assets and drivers to ensure safety of both. With data from ELDs and telematics equipment along with other equipment within a truck, such as dash cams, trucking businesses can become overloaded and will need to sift through the noise. You can focus on key performance indicators and potentially uncover problems you were not aware of. One short-haul trucking firm was able to remove 10 trucks from their fleet while increasing mileage by 10,000 miles per truck because of the data collected and analyzed within their TMS from ELDs.ABOUT THE AUTHORRobert Ramirez is the head of sales at Axele, a transportaon management system company. Find out more, visit www.axele.com. Visit us at The Utility Expo | North Hall | Booth 1505ICUEE is now

Visit us at The Utility Expo | North Hall | Booth 1505ICUEE is now

MODERN WORKTRUCK SOLUTIONS WWW.MWSMAG.COM AUGUST 202140SAFETYSAFETYIf your employees drive in order to complete vital job duties, they’re professional drivers. And without the proper training, they’re putting themselves, others, and your company at risk.According to the CDC, motor vehicle crashes are the leading cause of work-related deaths in the United States. This has cost companies millions of dollars. Worse yet, it’s caused thousands of people to suffer injuries or even lose their lives. It’s not just truck drivers either. These numbers include light-duty, non-CDL vehicle drivers.Whether your employees drive to a construction site, visit customer homes to spray for pests and rodents, or pickup dry cleaning, they face tremendous risk out on the road. By investing in light-duty vehicle safety training, you can save lives while saving money in the process.RISKS FACEDDriving is the most dangerous thing your employees do. Even if you have linemen fixing downed telephone poles, driving is more dangerous because employees are more likely to have an accident while behind the wheel.The CDC has shared some valuable statistics to back these claims: • Motor vehicle crashes are the first or second leading cause of death in every major industry group.• Work-related motor vehicle crashes are not just an issue for truck, bus, or taxi drivers. In 2018, 57% of workers who died in crashes on the job were not employed in motor vehicle operator jobs.• From 2003 to 2018, nearly 30,000 workers in the US died in a work-related motor vehicle crash.• In 2018, over 1,000 US workers driving or riding in a motor vehicle on a public road died in a work-related crash (that’s 24% of all work-related deaths).The fact is, these accidents happen to workers in all types of industries all over the country. It could happen to one of your people any day. Driving should be treated seriously by every company.The risks don’t stop at the people behind the wheel, though. Companies face tremendous financial risk from their non-CDL drivers. According to the CDC, in 2013 alone, work-related crashes cost employers $25 billion. Companies spent $65,000 per nonfatal injury and $671,000 per fatal accident.When it comes to an accident, you face the possibility of lost time from workers, rising insurance claims, large fines from court, and a bruised reputation. The costs of accidents are widespread and severe.PROTECTIONIf you employ a work truck fleet, chances are accidents are common, costly, and deadly in your industry. The good news is, accidents are entirely preventable. You just need to educate your drivers on safe defensive driving habits.Effective safety training reduces your drivers’ unsafe behaviors. The less unsafe behaviors, the less chances they have an accident. But, where does one begin with driver safety training? There are two options: • Make it yourself. Invest time and resources into creating homemade PowerPoints, safety resources, and lectures. This option saves some money upfront, but it takes up a lot of time. Results will vary depending on the effectiveness of your materials.Safety Training for Light-duty DriversLIKE IT OR NOT, YOUR LIGHT-DUTY DRIVERS NEED TRAINING By John Kudorlight-duty feature

AUGUST 2021 WWW.MWSMAG.COM MODERN WORKTRUCK SOLUTIONS 41• Invest in professional safety training. For many companies, the upfront investment in professional safety training is worth it. It saves time and resources, plus it’s guaranteed to reduce accidents and injuries. This means the training will quickly pay for itself and then some.WHEN TO TRAINAll of your drivers need safety training—newbies and veterans alike. So, what’s the best way to implement safety training, and when should it happen? It’s important to remember that safety training isn’t a single event. It must be a continual aspect of your company. It allows you to make safety an integral part of your company culture.That said, one of the best opportunities to implement safety training is when you first hire a new employee. Safety training as part of new-hire training sends the message that being a safe driver is one of the most important job responsibilities. It is recommended that you assign online defensive driving training to new employees directly after orientation. Have employees take this training on their own and outside of work, but pay them for the time. With new-hire safety training implemented, follow up with re-training and monthly safety meetings. This ensures that your employees will put essential defensive driving practices to use through their entire career with your company.DON’T WAITWhether your drivers are behind the wheel of a big rig, a pickup truck, or a sedan, they face serious risk. Accidents are common, costly, and deadly in nearly all industries. But that doesn’t have to be the case for your company.Investing in defensive driving training now could save money on insurance premiums, workers’ comp, and court visits later. Most importantly, it could save employees from pain and suffering. By investing in defensive driving training, you’re protecting your bottom line, your employees, and the motoring public.ABOUT THE AUTHORJohn Kuder is a senior instruconal designer at AvatarFleet, the creators of the non-CDL safety training course, The Fleet Safety Course. Find out more, visit www.avatareet.com.

MODERN WORKTRUCK SOLUTIONS WWW.MWSMAG.COM AUGUST 202142WORK TRUCK PRODUCTSEXTENDOBEDFOR WORK VANSExtendobeds designed for work vans will revolutionize the way you store and access your equipment and supplies on your fleet of work vans. Every system can be customized to meet your needs. Extendobeds can provide up to 220% storage volume when compared to typical storage/shelving systems. Productivity increases as work crews can get on/off jobsites quicker, allowing them more service calls per day. Injury claims are reduced because employees no longer have to lift heavy items from awkward positions or climb in and out of a van, injuring knees, ankles, and backs.www.extendobed.com FELLING TRAILERSDROP DECK AIR RAMPFelling Trailers’ new Air Ramp Slider Track System (patent pending) for the Drop Deck I (DDI) series is air brake equipped for its FT-20 I and FT-24 I trailers. The DDI Air Ramp System operates via an airbag system that works off the same supply as the air brake system. Thus, any air-brake-equipped truck can operate a Felling Trailer equipped with air ramps without any other external power source (e.g., battery, gas engine, or truck-powered hydraulic system). The air ramp system does the lifting for you. Flip the switch, and the air ramp system will raise or lower the ramps.www.felling.com LEGACY BUILDING SOLUTIONSFABRIC BUILDINGSTo house salt and sand at home base, Legacy Building Solutions offers fully customizable fabric structures. Legacy fabric buildings use a durable, rigid frame in place of the hollow-tube and open web truss “hoop” framing traditionally used for fabric structures. The strength of the structural steel frame provides several engineering advantages, most notably the ability to easily customize buildings to the exact width, length, and height required. In addition to long clear spans, the buildings have straight sidewalls that maximize the useable square footage inside the structure. The design also allows structural flexibility, including the ability to add lean-tos, mezzanines, sidewall doors, and more.www.legacybuildingsolutions.comFIAWINTER FRONTS AND BUG SCREENSFia custom-fit Winter Fronts and Bug Screens provide protection in all climates. Made from heavy-duty vinyl, the winter front promotes faster engine warmup and interior heat by limiting airflow to the engine. It also allows diesel engines to run at optimum operating levels. The bug screen is made from a heavy-duty mesh screen and protects the radiator and grill from bugs and debris. Both winter front and bug screen are included, along with Fia’s no drill Stick A Stud™ fastening system as well as the traditional drill on studs. Custom applications are available for both light- and heavy-duty trucks.www.gofia.com