Return to flip book view

NAVIGATORFall — 2020TM

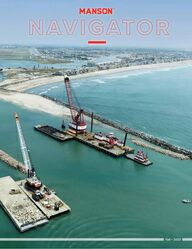

Established in 1905, Manson Construction Co. began as a small, family-owned Puget Sound marine pile driving business. Today, Manson thrives as an employee-owned company and takes great pride in our reputation for safely completing marine construction and dredging projects on time and on budget. Headquarters are located in Seattle, Washington with permanent oce facilities in Northern and Southern California, Louisiana, and Florida. Cover Photo & Credit - DB VALHALLA mechanically excavating the new public navigation channel at Anaheim Bay in California, while JV Partner Connolly-Pacic’s rig places rock at the Seal Beach Project. Photo credit—Bill King, SurveyorEditorial Team - Publishers – John Holmes and Fred PaupManaging Editor – Je ArvisoEditor – Jimmie CollinsGraphic Designer – Alvaro Leal de la TorreSta Writers – Sarah Ness & Jillian StrobelContributors - Thomas Barrett, Monica Blanchard, Douglas Boehm, Jordan Brown, Line Chan, Zach Chester, Erik Dolmseth, Justin Enjo, John Heckel, Ellen Heile, John Holmes, Jennifer Jacuzzo, Bill King, Daniel Nielsen, Pary Palanisamy, Kelli Rider, John Roques, Carey Shannon, Tommy StephensManson Construction Co. is an Equal Opportunity Employer.© 2020 Manson Construction Co. MANSON™ is a trademark of Manson Construction Co.No part of this publication may be reproduced or transmitted in any form or for any purpose without the express written permission of Manson Construction Co.TM| MESSAGE FROM THE PRESIDENT |John HolmesManson President & CEOThis has been a year lled with unanticipated challenges, but also a year where Manson has overcome those challenges and continued to successfully operate and serve our clients. The Manson Navigator has always served as a means of acknowledging the contributions of our employees, which is especially appropriate for this issue. You may also notice that our marketing team has been transitioning the organization and content of the Navigator. For this Fall 2020 issue, we have shifted to feature-focused, in-depth coverage of selected topics. In addition, more regular updates can be found on Manson’s LinkedIn and on our new website blog. We hope you enjoy the new format and alternative sources of information.Throughout our history, Manson has maintained a reputation for the best people and best equipment in the industry. Following that tradition, in October 2020, Manson announced the construction of its new hopper dredge FREDERICK PAUP, which will soon commence at the Keppel AmFELS shipyard in Brownsville, TX. Also following Manson tradition, the dredge design is a culmination of more than a decade of planning and collaboration by Manson personnel. Their technical expertise and operational experience informed a design with superior dredge performance and special attention to crew access and safety. When completed in 2023, the new dredge—at 15,000 cubic yards capacity—will be the largest self-propelled hopper dredge in the U.S.A., and the largest single equipment investment in Manson’s history.As we began the year, I doubt any of us anticipated the impact COVID-19 would have on our industry or our country. But with core values and a safety culture founded on “taking care of our people,” I believe we rose to the challenge, adapting the way we work in order to continue operating while keeping our employees safe. Those eorts will continue, and I once again want to thank all of you for your commitment to our safety culture and keeping yourselves and coworkers safe. In this edition of the Navigator we highlight three Manson employees who took the time to identify and report either a hazardous condition or near miss incident. Hazard/Near Miss reporting provides training opportunities for the rest of the organization and is a key element in the eort to improve our safety performance and safety culture.Lastly, this edition of the Navigator includes a feature on our IT group. Although most of their work is done behind the scenes, they provide the technology and IT infrastructure that allows the rest of us to be productive and our company to be competitive. Their ability to adapt to new challenges in support of our operations was never more evident than during this pandemic. They provided the technology, hardware, and training as our organization quickly transitioned into a world of remote working arrangements and virtual meetings. In more normal times, they often travel to remote sites or work o-hours to support our company while minimizing disruptions. Many thanks to this dedicated Manson team. Challenges, Changes, and Perseverance1 Fall 2020 | Manson Navigator

PHOTO CREDIT | LINE CHAN — LEAD ENGINEER| CONTENTS |The crew of the NJORD and the PETER M. positioned on the deck of the NJORD with the old 55 cubic yard (CY) Cable Arm bucket on left, and their brand new 55 CY bucket on the right. Left-Right: Bryce Whitcom/Deck Engineer, Matt Rizo/Deckhand, Kyle Gardner/Deckhand, Elling Steinsvik/Tug Captain, Ryan Huffaker/Deck Engineer, Rod Kiefer/Crain Operator, Garrett Do/Deckhand, Matt Urqhardt/Deckhand, Lee Long/Deckhand, Robert Nooner/Deckhand, Drew Steverson/Crane Operator, Jeff Rickard/Tug Captain, Steve Penick/Crane Operator, Brad Kirkland/Boat Captain, Front Center: Charlie Mann/Field Engineer Fun Fact:One scoop of the 55 CY Cable Arm bucket is equivalent to approximately ve dump truck loadsNEW EQUIPMENT: INCREASED EFFICIENCYETHICS & BUSINESS RESPONSIBILITY CREW CONNECTIONNEWS FLASH ENVIRONMENTAL HEALTH & SAFETYTHE RIG REPORTTEAM FOCUSPROJECT SPOTLIGHT MANSON PEOPLECONSTRUCTION SNAPSHOT DEPARTMENT FEATUREWHEN COVID-19 MEETS CULTUREAWAY FROM HOMEMANSON PRESENTED AEU SAFETY AWARDHEROES IN HIGH VISIBILITYTHE PLANNING OF AMERICA’S LARGEST HOPPER DREDGEBEHIND THE SCENES WITH THE IT DEPARTMENTTHE RECONFIGURATION OF ANAHEIM BAYRETIREES AND MILESTONESTHE MUKILTEO FERRY TERMINAL SUPER COLUMNTHE MANSON LEARNING NETWORK3 134 155187 2011 21CONTENTS2Manson Navigator | Fall 2020

John D. Heckel Corporate Ethics & Compliance OcerWhen COVID-19 Meets CultureNo one saw it coming and no one was prepared. In hindsight, we all realize now that we should have been planning for something like this all along. This is the story of how a crisis brought us together as employees and forced us to quickly adapt to a new normal. It’s also a story of how an industry came together to share best practices in a crisis.When news rst broke about a virus called COVID-19, it was speculated that it was no more than another cold or u, right? As more information developed about how contagious this virus was, and how deadly it could be, it became evident to Manson leadership that we needed to immediately implement precautions. Manson formed a COVID-19 Task Force to nd out as much as we could and to centralize communications and planning. The only thing we were absolutely certain of was that we were committed to the safety and well-being of Manson employees rst and foremost. Our focus centered on what needed to be done to protect employees and their families from contracting the virus, and at the same time meet our contractual obligations to our clients while keep our essential operations functioning.We set out to answer the classic questions “who, what, where, how and when.” We began to read everything we could about the virus, starting with searching the Centers for Disease Control (CDC) website. Early on, however, while the CDC and the World Health Organization had provided some guidance on protocols to prevent transmission of the virus, no one knew for sure exactly how the virus was spread and what was necessary to protect the health and well-being of everyone. With so many questions still unanswered, in early March 2020 we implemented a Work From Home policy and a Don’t Come To Work If You Are Sick policy. One of our goals was to reduce the occupancy of our oces to enable better social distancing.Our IT department quickly provided all employees with access to video meeting software, which meant we could limit in-person meetings. Manson’s President, John Holmes, hosted COVID-19-specic Department Head calls every morning to communicate, coordinate, inform, and share feedback. We modied our plans as new information was developed and we began sharing our response plan with clients, stakeholders, and interested parties via the Manson website.Our Chief Operations Ocer, Jim McNally, hosted twice-weekly COVID-19 operations calls with all area vice presidents. We created a COVID-19 SharePoint site to collect local/area regulations, response plans, tools, resources, etc. We also implemented schedule planning and log-in sheets to aid in contact tracing. Our executives participated in industry groups and forums to discuss best practices in safeguarding employees from contracting the virus. We compared our plans to those developed by our partners and others in our industry, and implemented the best practices of all plans. What you may not know is that while construction companies are rabid competitors when it comes to bidding and estimating work, we are willing collaborators when it comes to safety and protecting the public, ready to share best practices and solutions with one another.We identied a Point of Contact (POC) for each oce, jobsite, vessel, and work location. The POC is responsible for developing and implementing a site-specic COVID-19 plan that meets the federal, state, and local laws, as well as reects any client’s notication requirements if someone were to test positive while working at the site. In addition, oce layout needed to account for social distancing and Plexiglas barriers were erected around high contact work stations. Protocols for temperature checks were developed, masks required, and hand sanitizer and signage reminding of protocols distributed.How a Pandemic Changed How We Operate, but Didn’t Change Who We AreThe only thing we were absolutely certain of was that we were committed to the safety and well-being of Manson employees rst and foremost.“ “| ETHICS & BUSINESS RESPONSIBILITY |3 Fall 2020 | Manson Navigator

| NEWS FLASH |Manson Construction Co. has won the American Equity Underwriters (AEU) safety award the past two years in a row – for 2018 and 2019. The AEU administer Manson’s insurance through the American Longshore Mutual Association (ALMA). Every year since 2007, AEU recognizes the ALMA member with the most eective safety program. AEU presents awards to companies in seven dierent categories including large shipyard, medium shipyard, small shipyard, large stevedore, medium stevedore, small stevedore, oshore industry, marine construction, and advantage by AEU member. Manson won the award in the marine construction category. The winner is determined by the following three factors: frequency of lost time cases, severity of lost time cases, AEU Safety Benchmark®. This benchmark is generated from AEU loss control inspections where the company is provided with a metric by which they may evaluate themselves on management commitment, supervisor participation in the safety program, eectiveness of the safety sta, and compliance with previous AEU loss control recommendations Manson EHS Director Dave Howard was interviewed earlier in the year for a video AEU is putting together featuring all of last year’s winners. The previous year, the award was accepted by Dave Howard and Claims Manager Jan Lindsey at the annual ALMA conference.Safety is everyone’s responsibility at Manson and this award demonstrates the commitment of Manson employees to a strong safety culture. Manson Presented with AEU Safety AwardWhat you may not know is that while construction companies are rabid competitors when it comes to bidding and estimating work, we are willing collaborators when it comes to safety and protecting the public, ready to share best practices and solutions with one another.“ “Perhaps the most important process put into action by the Task Force was centralized tracking of suspected COVID-19 cases. Manson’s Claims Manager, Jan Lindsey, contacted and interviewed all Manson employees who were, or could be, COVID-19 positive. She informed employees of our isolation protocols and let them and their job sites know when it was safe to return to work. All the above was put together in record time. After reecting on how we tackled this dicult and challenging situation, it occurred to me that we had subconsciously followed Manson’s three core values: Take care of people rst and always; Do the right thing; and Find a better way.It has been said that tough times don’t change who you are, they just magnify who you are. Covid-19 may have changed the way we operate, but it didn’t change who we are. Manson’s culture of compliance made it easy to implement a program that relied on all employees adhering to the protocols to make our program successful. LESSON LEARNED: When faced with dicult and challenging problems and when you have a healthy corporate culture–doing the right thing is instinctive. PHOTO CREDIT | ALVARO LEAL DE LA TORRE—GRAPHIC DESIGNERWRITTEN BY | CAREY SHANNON — CORPORATE EHS SPECIALIST 4Manson Navigator | Fall 2020

| THE RIG REPORT |The making of a dredge is no simple feat, and the planning and design of the largest self-propelled trailing suction hopper dredge in the USA has certainly been no dierent. For more than a decade, the new vessel – which is set to be christened the FREDERICK PAUP – has been an inkling in the back of Henry Schorr’s mind. Henry, Manson vice president and Gulf & East Coast dredge manager, has been in this industry for quite some time and has seen a fair number of new vessels join the eets of American dredging companies. He joined Manson Construction Co. in 1999, just as the dredge BAYPORT was christened and put to work. He has helped get new cutterhead dredges – such as the LEONARD J – completed and out on the water, and even saw Manson’s current largest hopper, the GLENN EDWARDS, from planning through to completion. From start to nish, the GLENN EDWARDS took around ve years, with much of the vessel design happening simultaneously alongside construction. Since nal delivery, it has been a highly successful investment. “After seeing how successful it was, we started proposing that we look at a second dredge,” Henry says. In 2008, Manson, led by Henry’s analysis, began planning for a bigger, better, and more ecient hopper. “I’ve got to give Henry the credit of analyzing the dredging market and understanding the abilities that we needed based on what the market needed,” says Shawn Hillis, former vice president of equipment who is retiring at the end of 2020 after a 42-year career with Manson. After ten years of analyzing and planning, in 2018 Henry and his team got the go ahead to engage with naval architect Hockema Whalen Myers Associates, Inc. (HWMA) to begin the design phase of the new dredge. This time would be dierent, though. “The GLENN EDWARDS was basically just a goliath version of previous dredges,” says Shawn. “The improvements for this dredge are going to be enormous.”A ten-person Manson team, including Henry, Shawn, and Project Manager Jordan Brown, just to name a few, worked over every excruciating detail with HWMA to produce a complete and detailed design to be fully approved by the American Bureau of Shipping (ABS). Jordan, who prior to this assignment was engineering manager for Manson’s Gulf & East Coast dredging operations, describes months of day-long meetings between the equipment group, the project design team, and HWMA. They would discuss how the pieces and parts of the dredge t, how it would be maintained in the future, the advantages and disadvantages of every proposed change, and, perhaps most informatively, the lessons learned from the GLENN EDWARDS. “We tried to make substantial changes for the benet of the dredge’s performance and the safety of the crew,” Jordan says. “I had not previously worked directly with the equipment department much until this project, but it is their experience with prior builds, vendors, and gear that helped drive the nal design package.” THE PLANNING OF AMERICA’S LARGEST SELF-PROPELLEDHOPPER DREDGEWRITTEN BY | JIMMIE COLLINS—PROPOSAL & MARKETING MANAGER5 Fall 2020 | Manson Navigator

| THE RIG REPORT |According to Shawn, many of the people involved in this project have a lot of longevity with the Company and have participated in creating several of the vessels in Manson’s eet. “They wanted to make sure the changes they were contemplating were truly in the best interest of the dredge and the ability of the dredge and its crew to do their job,” Shawn says. The chance to get input from everyone and see how everything interacts helped the team to cover all of their bases, Henry added. “We would sort out individual systems and determine the best approach to cover the downside risks and make sure we got the product we wanted out of it in the end.”Some of the dierences on the new dredge are due to regulatory requirements, but also improvements to the abilities of the dredge. The FREDERICK PAUP will be Manson’s rst fully diesel-electric hopper dredge in the eet, operating on only ve diesel-electric engines as opposed to the 15 diesel engines on the GLENN EDWARDS. This makes it more ecient, more powerful, as well as more environmentally friendly, meeting the Environmental Protection Agency’s Tier 4 standards for air quality.Other updates include changes to the drag arms that will make bringing them on board an automated process, meaning it is both quicker and safer for the crew. The move to electric motors also allowed exibility in the design to improve areas near the drag arms. By placing a motor adjacent to the dredge pump we eliminated the need for an engine housing at the top. This creates safer conditions as there’s no longer need to spray service water over the driveshaft bearings which often freezes on deck. Additionally, the vessel design incorporates in-hull passageways allowing crew to transit the vessel end-to-end without having to go over the top deck.“I think it’s rare that a company like ours continues to design our own dredges and pumping methodology,” Shawn says. “The guys who are working on this actually know the job; they know the work. They’ve been on this equipment and they know what we actually need.”After several iterations and nearly two years, the design phase of the FREDERICK PAUP is complete. Jordan Brown has been named project manager for the construction phase of the project, and a contract has been signed with Keppel AmFELS to complete the build at their Brownsville, Texas, shipyard by spring of 2023. “The construction timetable will be based on the shipyard’s capabilities, but we will see fewer complications since we have a fully completed design,” Henry says.Going forward, Jordan, along with Brad Martin – incoming vice president of equipment – as well as Sean Hayden – the technical lead for the project, will be spending a lot of time in Brownsville over the next few years.Jordan, who feels fortunate just to be a cog in the wheel of this project, is excited for the next phase. “A project of this size presents certain challenges, but this isn’t something we get to do every year and I am lucky to be a part of it,” he says. “I probably have another 20 to 30 years with Manson, so it will be really cool to help get this dredge delivered and then see it work throughout the rest of my career.”PROJECT TEAM — DESIGN PHASEHenry Schorr — Vice President, Gulf & East Coast Dredging ManagerShawn Hillis — Vice President of Equipment Jordan Brown — Project ManagerMike Warwick — Vice President, Dredging Engineering & Estimating Manager Mike Coakley — Gulf & East Coast Equipment ManagerDaric Latham — West Coast Equipment ManagerJohn Stilwell — Electrical SuperintendentNick Maddox — Assistant Engineering ManagerPaul Huber — Equipment Engineering ManagerILLUSTRATION CREDIT | ALVARO LEAL DE LA TORRE—GRAPHIC DESIGNER6Manson Navigator | Fall 2020

| PROJECT SPOTLIGHT — SEAL BEACH |ANAHEIM BAYTHE RECONFIGURATION OF PHOTO CREDIT | BILL KING—SURVEYOR WRITTEN BY | JIMMIE COLLINS—PROPOSAL & MARKETING MANAGER7 Fall 2020 | Manson Navigator

| PROJECT SPOTLIGHT — SEAL BEACH |Huntington Harbor, located at the northwest corner of Huntington Beach, CA, and developed in the 1960s, is the picturesque site of ve man-made islands featuring more than 500 bayfront homes. Bordering Seal and Sunset Beaches, the only passageway in and out of the harbor takes pleasure boaters along a water network that stretches across the southern end of the Seal Beach National Wildlife Refuge, under the Pacic Coast Highway (PCH) bridge, and into Anaheim Bay. It is here where boaters may nd themselves within 400 ft. of a naval ship loading or unloading ammunitions. Naval Weapons Station Seal Beach is a 5,000-acre base responsible for weapons storage, loading, and maintenance for ships of the United States Pacic Fleet. The U.S. Navy has contracted the Manson/Connolly Seal Beach Joint Venture to recongure the Anaheim Bay area, which currently services about 40 ships a year. The changes would create a new public boat navigation channel farther from Navy operations, and replace the World War II-era ammunition pier, providing a new berthing location for larger vessels, and moving ammunition loading away from the PCH. 8Manson Navigator | Fall 2020

| PROJECT SPOTLIGHT — SEAL BEACH |“There are several parts to this ve-year project, but right now, it’s all about getting that public navigation channel open,” says Tommy Stephens, Manson Construction Co. project manager who is heading up the Seal Beach project. The project team has spent the last 11 months juggling the needs of civilian boaters, the U.S. Navy, neighboring Seal Beach and Surfside communities, as well as making way for sea turtles heading to and from the wildlife refuge, the only such refuge on a military installation in the nation. The new channel follows the lower jetty – often referred to as the East Jetty, cutting through the East Mole – then turns east under the PCH bridge. Creation of the channel has required dredging above and below water, an operation supported by Alex Kolessar, the lead dredge engineer on the project. “There are multiple dredge sites, as well as multiple disposal sites,” Alex explains. “The material has to be transported to specic disposal locations to meet particular ll requirements and meet the project specications.” So far approximately 550,000 cubic yards of material has been excavated from the new channel using the DB VALHALLA, the NJORD, or the VULCAN for mechanical clamshell dredging, and the H.R. MORRIS to perform the cutter suction dredging portions. In total, more than 1 million cubic yards of material has been moved to date.“The challenging thing is to track all of the material quantities and make sure we have enough material to accomplish all of our goals,” Alex says.In the end, the creation of the new channel and the causeway that will separate the public from the Navy will be benecial to the public, says Sergio Covarrubias, the engineer supporting scheduling and coordination. “Right now, anytime a Navy ship comes in, they have to shut down the channel for sometimes up to an hour, meaning anyone wanting to get in or out of Huntington Harbor has to wait,” he says. “Once the new channel is in, that won’t be a problem anymore.”Sergio streamlines communications between Manson, the client, the joint venture partner and any subcontractors, working with everyone to ensure the project sticks to its timeline. Tommy Stephens – Project Manager Jim Davis - EngineerClaire Parker – Project AdministrationSergio Covarrubias – EngineerBill King – SurveyorAlex Kolessar – EngineerPete Hernandez – SSHO Kristen Ewert – EngineerJon Denison – Lead LevermanKyle Funke – EngineerPHOTO CREDIT | BILL KING—SURVEYORAbove: In June 2020, the cutter suction dredge H.R. MORRIS excavates to create the new public navigation channel at Anaheim Bay, CA, while the VALHALLA mechanically dredges with a clamshell bucket on the West Mole in the background.PHOTO CREDIT | BILL KING—SURVEYORKyle Brown – Project EngineerToby Walker - ForemanPROJECT MANAGEMENTMANSON CONNOLLY-PACIFICBelow: JV Partner Connolly-Pacic steadily placing rock at the end of October 2020 to create the new public navigation channel. Once complete, the nal cut will be made to open access to the new passageway.9 Fall 2020 | Manson Navigator

| PROJECT SPOTLIGHT — SEAL BEACH |Joint venture partner Connolly-Pacic is responsible for all rock installation. The job in total requires approximately 820,000 tons of rock. The rock installation is slow and steady work. One of the biggest challenges of the job is coordination with the rock operation and sequencing work to remain ecient. “Throughout this process, the existing public channel needs to remain open,” Tommy explained. “Public safety and boater awareness has been an everyday focus.” The day-to-day operations require an artistry in coordination and communication, getting everyone lined up and ready to go, but Tommy says Manson is particularly well-suited for the job. “Manson has been doing this work for over 100 years and most recently completed the Middle Harbor redevelopment which consisted of a very similar operation in Long Beach, CA,” he says. Working on this project has been unique given the multitude of dynamic tasks both on the dredging and civil construction sides, according to Kristen Ewert, engineer in charge of cost and quality control at Seal Beach. “Thankfully we have great people resources down here in SoCal, and a wealth of experience,” she says.By the beginning of 2021, Manson plans to remove the current land barrier which will open up the new navigation channel to the public. We will then begin to recycle material recovered in the dredging process to create the physical barrier – the causeway – that will close o naval operations to public access near the channel. The causeway, planned for completion by the end of March 2021, will also serve as a truck path, culminating in a turnaround at the head of the new wharf. The new pier and recongured causeway will provide for berthing of larger ships to safely enter Anaheim Bay for loading and unloading of armament, allowing for increased naval operations at this key military installation. “It is a good safety measure for the public, but it will also be an easier transit out to the ocean,” Kristen says.The illustration above shows changes that will be made to the Anaheim Bay area, including the opening of a public navigation channel, building of a causeway to separate military access areas, and the construction of a new pier.ILLUSTRATION CREDIT | ALVARO LEAL DE LA TORRE—GRAPHIC DESIGNERFACTS & FIGURES820,000TONS OF ROCK TO BE PLACED1,350,000CUBIC YARDS OF SAND TO BE DREDGED900PILES TO BE DRIVEN1,100LINEAR FEET OF NEW PIER TO BE BUILT$155,000,000TOTAL PROJECT VALUE10Manson Navigator | Fall 2020

| CONSTRUCTION SNAPSHOT — MUKILTEO FERRY TERMINAL |As part of the Mukilteo Ferry Terminal (Phase 2) Construction project, Manson’s Mukilteo project crew recently completed construction of an overhead loading structure utilizing a “super column” to accommodate pedestrian boarding. The overhead loading structure (OHL)is a unique design that changes elevation to accommodate varying sizes of ferries docking throughout the entire tide cycle. This movement is accomplished through the use of a large hydraulic cylinder. Manson installed what the project crew nicknamed the “super column” to support the hydraulic cylinder and structure. [See illustration on page 12 for a depiction of the “super column” which includes a drilled shaft and large steel structures.]To start, the crew built a work platform able to withstand loads from the chosen drill rig using a vibratory hammer to drive 24 in. diameter falsework piles. After installing the piles, the main structure was picked, set, and pinned to the piles. Some of the challenges encountered during the platform design were limitations on allowable temporary pile locations and available sizes and lengths of falsework beams. The team constructed the main platform structure prior to mobilizing it to the site, thereby minimizing time spent on the job site. An opening was left in the platform to act as a template for the casing install and a vibratory hammer was used to drive a 10 ft.-6 in. diameter casing down to grade. Once the casing was installed, Manson ew — slang for hoisting with a crane — the drill rig onto the platform and Manson’s subcontractor, Condon-Johnson, began drilling. Manson supported Condon-Johnson throughout the drilling with PHOTO CREDIT | MONICA BLANCHARD—FORMER PROJECT MANAGERTHE MUKILTEO FERRY TERMINALWRITTEN BY | KELLI RIDER—PROJECT ENGINEER &JILLIAN STROBEL—PROPOSAL & MARKETING COORDINATORSUPER COLUMN11 Fall 2020 | Manson Navigator

Project Management: Kelli Rider — Project EngineerErik Dolmseth — Superintendent Matthew Kelly — Field EngineerMadeline Brisson — Field EngineerJason Prohaska — ForemanJohn Garsee — ForemanGraydon Bennett — Foreman| CONSTRUCTION SNAPSHOT — MUKILTEO FERRY TERMINAL |hook support and disposal of spoils and slurry. The shaft had to be drilled 16 ft. below the tip of the casing. The slurry elevation in the casing was maintained at a minimum of 10 ft. above the outside water level creating enough head pressure to keep the hole open until the concrete was poured. Once the driller reached the nal depth, the rebar cage was tripped and set in the hole. To trip the cage, the project team engineered pick points located where the cage was reinforced with additional bracing to prevent buckling. Three pick point locations were needed for the 115-ft. long cage and multiple rolling blocks were used to allow one hook to grab the cage in these three locations. Another hook, designed to withstand the entire cage weight when vertical, grabbed a support at the top of the cage. The exibility of the cage makes this a unique and challenging lift. The project team studied the loads in depth to understand how the cage would want to react before starting the lift, and the rebar cage was tripped the night before to ensure the pour tasks could be completed in only one day.To prevent creating abnormalities in the concrete, the next steps had to be completed continuously in one day. First, the drillers cleaned out the hole one nal time to remove any sediment that settled out of the slurry overnight. Next, the cage was set in the casing to proper elevation and the pour began. The concrete was then deposited at the bottom of the hole using a tremie, essentially a watertight pipe with a conical hopper used for underwater concrete placement. Slurry was removed from the top as the concrete displaced it. It was important to keep the tremie submerged in concrete until the very end to prevent voids, or cavities, and minimize the amount of bad concrete at the top of the shaft. Once the concrete cured, the shaft concrete was tested for voids by using a test known as crosshole sonic logging. This test uses an ultrasonic signal to detect possible defects in the concrete. The project team made a secondary pour up to the required elevation after chipping the top until sound concrete was reached. Next, the column was poured and a steel cylinder seat was grouted on top of the column. Following this, a 6 ft.-7.5 in. interior casing was set on top of the secondary concrete and the annulus space between the interior and exterior casing was lled with concrete.All this work was done 40 ft. below the top of the casing in a conned space. Access was a challenge, since every added piece reduced the amount of remaining space to work. By managing the work sequence and designing varying access options for dierent stages and elevations, the team was able to successfully install each piece.The tolerances on the “super column” are extremely tight in order to make sure all parts are functioning as designed. It was a challenge to verify that all tolerances were being met at each step of the install. Large steel pieces were used in the design in order to attach the overhead loading cab to the foundation structure. The steel pieces were machined and t tested to conrm proper fabrication prior to being shipped to the site. Once onsite, the two-piece bearing housing was shimmed o of the concrete that was poured between the casings. The gap between the bearing housing and inner casing was grouted and the lift shaft set inside the bearing housing. Surveying was often used to check that all tolerances were being met and temporary supports were used to keep pieces in their proper positions prior to the nal installation. Once the lift shaft was installed, the “super column” was complete and the project crew was able to move on to completing the overhead loading structure.FIBERGLASS SHROUD ASSEMBLYBEARING HOUSING ASSEMBLYLIFT SHAFT & CAB HOIST ASSEMBLYOHL TRANSFER SPAN & LOADING CABPASSENGER APRON ASSEMBLY12Manson Navigator | Fall 2020

| CREW CONNECTION |It takes a special person to work on the water. Since making a career out of marine construction often requires travel, it also takes a special person to work away from home. Manson recognizes the many employees that make a tremendous sacrice to support the work that we do on the nation’s waterways, and this requires spending time away from family. This article and the following proles are meant to honor all of the people who make that sacrice.There are a number of dierent scenarios for the people who work away from home. Some folks are assigned to a vessel and work a regular rotation – examples of this would be those who work on the hopper dredges or oshore on the E.P. PAUP. Others work on projects that are located far enough from home that they must temporarily relocate to a new town. And some folks who work on projects rotate in to the jobsite in periodic rotations.The following proles present the realities of three people who work for Manson on projects away from home: Pary Palanisamy, Ellen Heile, and Randy Williams.What attracted you to dredging?As a State University of New York (SUNY) Maritime graduate, I went to work on a ship and a few years later I started with Noble Drilling on a drill ship. A friend of a friend who was a captain on a dredge for Manson told me about dredging. Three and a half years ago I pursued this vocation, and have now achieved the position of chief engineer on the GLENN EDWARDS. What rotation do you work? I work three weeks on and three weeks o. Can you describe your family at home? I have a wife and a ve-month old daughter named Lina. Do you enjoy being part of a consistent crew? It would be tougher if there were new faces every time you go out. You tend to learn what people are good at, how they operate, how the team functions, each role and position, each strength and weakness. Is there a certain personality, character, or work style that allows someone to manage this type of work rotation? I like to work with people who are easy going and go with the ow. I like to joke around a lot but I keep it good-natured. You literally spend half your life with the guys on the dredge – you have to get along.How does your family cope when you aren’t around? My wife is strong and independent. She would love for me to be home more, but she accepts that this is what I do and understands that there will be sacrices. What about missing some of the signicant events in your life? During my time o I am daddy daycare. Because of the rotation, I think that I spend more quality time with my daughter, but I still miss being there every day. How have the changes to technology aected your ability to stay in touch? When I was on the drill ship we had to buy satellite phone cards to call home. There was one email account on the ship. I would have to write out a message and give to the captain, he would send the email and then let you know when you got a response. It typically took a few days. Now I have cell phone coverage 95% of the time. The ability to FaceTime and text are game changers for staying in touch when working away.NAME: PARY PALANISAMY POSITION: CHIEF ENGINEER ON THE GLENN EDWARDS HOMETOWN: PHILADELPHIA, PAHOMEAway FromWRITTEN BY | JOHN ROQUES—SENIOR VICE PRESIDENT, GULF & EAST COAST REGIONAL MANAGER13 Fall 2020 | Manson Navigator

| CREW CONNECTION |What family do you have back home in McComb? My wife, Lashanna; son, Rendarus, 22 years old; and daughter, Azarius, 17 years old. Why did you get into marine construction and what other jobs have you had? I worked a lot of years in the Gulf on a drill rig, but I have been in general construction for the last 15. For the last ve years I have worked in marine construction as a carpenter. I have been with Manson for the last two years and before that on a Sabine Pass dock job.How often do you get back home? I try to get home every other weekend. It is a ve-hour drive and I leave after the shift on Saturday. I start heading back in the afternoon on Sunday. It is really just a quick check in. I enjoy having a little time o to spend at home.What is the best/worst part of the job? The best part is the paycheck, we all have to make a living. The worst part is being so far away that you can’t get back for something small.How does your family cope with you being gone? My wife is used to this set up. When I was oshore I was gone for long stretches and she got to where she can take care of everything.How do you stay in touch? Nothing special, I just call my wife in the morning as she is getting ready for work and then I check in again when we break for lunch. It is nice to be able to talk to her twice a day.NAME: ELLEN HEILEPOSITION: FIELD ENGINEER, PIER 8 WHARF CONSTRUCTION, SAN DIEGO HOMETOWN: I CALL THE CALIFORNIA BAY AREA HOME. I WENT TO COLLEGE IN BERKELEY AND THEN WENT TO WORK ON A JOB IN THE BAY. NAME: RANDY WILLIAMS POSITION: FOREMAN ON THE PORT OF PORT ARTHUR BERTH 5 WHARF EXTENSION HOMETOWN: MCCOMB, MISSSISSIPPI Why were you interested in relocating? The Area Manager mentioned the possibility of relocating some time before my last job was complete. I remembered the conversation and pursued the relocation. I am at the beginning of my career and I see the importance in working in dierent settings, with dierent people on dierent projects. Because I am at this point in my life, I don’t have serious commitments that conict with relocating for a job. I view this as a real learning opportunity. Did anyone move with you or did you leave anyone behind? My boyfriend, E.J., moved with me. Though his job is based in San Diego, he works remotely, so that made his move possible. How was the move? The move was harder than I expected. I suspect that is primarily because of COVID-19 protocols. Everything was getting shut down just as we were trying to nd an apartment and establish a routine. It was particularly dicult to nd an apartment because of the diculty in coordinating visits with the landlords. I wasn’t ying, so travel from Southern to Northern California was time consuming and dicult. How are you enjoying San Diego? I like it; I am outdoorsy. We are still looking for good places to hike and be outdoors. How do you stay in touch with family and friends back home? I try to text or call parents each day. I play virtual games over Skype with my mom. The virtual connection goes a long way. The pandemic has made it very dicult to stay in touch no matter where people are located. Is there anything else to say about accepting a position that required relocating? It was a great decision for me. I have enjoyed learning how dierent practices are from the dierent areas. The project team is remarkable and everyone is close, probably because we all relocated to be here. 14Manson Navigator | Fall 2020

The National Safety Council denes a near miss as an unplanned event that did not result in injury, illness, or damage, but had the potential to do so. It is a fortunate break in a chain of events that prevents an injury, fatality, or damage; in other words, a narrow escape from danger or disaster.This year, several Manson employees embodied that “fortunate break in the chain of events.” The actions of these individuals prevented severe injury or equipment damage. Here we take the opportunity to give recognition to those whose interventions help maintain a safe working environment. We focus not only on what could have happened but what drew these individuals to take action. THE LONG HOT SUMMER Jacksonville, Florida, experienced its highest recorded temperature of 105°F this past July and averaged a high of 90°F throughout June, July, and August. The crews at the Blount Island Martine Terminal (BIMT) Wharf Rehabilitation – Phase 2 project perform rigorous tasks in this hot environment such as pile driving, concrete pours, and demolition work all while wearing life jackets, work vests, hard hats, work boots, and other heavy protective clothing. The project team implemented measures to protect workers from heat illness such as providing several 10x10 ft. pop-up tents for shade, water, sports drinks, 36-in. portable barrel fans, an evaporative cooler, a portable AC unit, and frequent training sessions on working in hot weather. On August 28, 2020, while on the jobsite, Manson Welder Isaias Benitez observed possible symptoms of heat illness in a third party iron worker and immediately took action. Isaias has worked for Manson since early 2019, primarily as a welder on the project, but he has also worked with both land and water pile driving operations, xing rebar issues, installing trench drains, and placing concrete. Isaias noticed the iron worker sitting under one of the shade huts about 50 ft. away, and that he appeared to be ill. Isaias described what he encountered: “I knew that there was something wrong. I went to go check on him and when I approached him he was quite pale and pasty looking. I tried to talk to him but I could barely understand him as his speech was very slurred. I tried to oer him a liquid IV but he did not accept it. He continued to dry heave and I told him we needed to go to the trailer and see the Site Safety Health Ocer (SSHO). I helped him to his feet and escorted him to the trailer where he could sit in the air conditioning.” After some rest, the iron worker made a full recovery within a couple of days. Isaias credits his awareness about heat illness with the many times that it was discussed on the project. He himself has also experienced symptoms similar to those of the iron worker. “I feel that between all of the times that the topic is discussed onsite and in safety meetings and having also experienced similar symptoms previously, that I have become more aware of the conditions to look for in regards to how well how that person is feeling. I also understand what needs to happen to help aid recovery from those feelings and condition.”Heat stroke is the most severe of all heat-related injuries including heat exhaustion, heat cramps, sun burn, and heat rash. The body can reach a temperature of 103°F or higher and it is considered a medical emergency. Isaias’s timely intervention potentially prevented the most deadly of heat related illnesses. Heroes inHIGH VISIBILITY| ENIVRONMENTAL HEALTH AND SAFETY |WRITTEN BY | CAREY SHANNON—CORPORATE EHS SPECIALIST Isais Benitez — Welder — working at the BIMT Wharf Rehabilitation project in Jacksonville, FL.PHOTO CREDIT | DOUGLAS BOEHM—EHS SPECIALIST 15 Fall 2020 | Manson Navigator

| ENVIRONMENTAL HEALTH AND SAFETY |A CHANGE IN THE WIND Those who work in the Pacic Northwest are fortunate in that destructive weather events like hurricanes and tornados are extremely rare. However, it does not take a particularly strong gust or sustained wind to create a potential for damage or injury. Jason Prohaska has worked for Manson since 2012 as a foreman. Among the eight projects he has worked on are two seawalls in western Washington, a cruise ship berth in Alaska, and wharf rehabilitation in Florida. His current project is the Mukilteo Ferry Terminal where his experience proved to be valuable on a windy day. On September 2, 2020, the HARRY M prepared to move Derrick Barge 24 into position to connect a dolphin anchor chain. Jason was prompted to take action when he noticed that the weather had picked up with a sustained wind of 20 mph out of the north and that it would be very dicult to move the DB24 with the 2000 horsepower tug HARRY M in this condition. The worst case scenario for this incident was the potential for the DB24 to slide into the new ferry dolphin and damage it. As the foreman, he met with the HARRY M captain and the project superintendent following an all stop of operations. It was decided to discontinue operations for the day. The project crew returned and completed the dolphin anchor chain connection the following morning. There is always a temptation to push the limits of the equipment in challenging elements to get a job done. The dolphin is built to take a beating and damage was unlikely. However, Jason and the rest of the Mukilteo Ferry Terminal project team were wise to not take this risk and exercised good judgement on this windy afternoon. A ROUTINE INSPECTION FINDS A CRITICAL ITEMOn August 27, 2020, the Deck Captain of the ROBERT M WHITE, Marcos Lozano, was in the midst of performing a routine inspection of a newly arrived aerial lift at the project yard in Mobile, Alabama, when he noticed that the switch to control the lift from the ground was broken. The aerial lift can only be moved and lowered by an occupant in the lift’s basket. The primary hazard for a fall from an aerial lift is ejection from the basket due to the lift’s jerky movements. This potential for ejection is why an occupant is required to wear a personal fall arrest system while using the lift, even with railing on all four sides of the basket. Without the ability to control the lift from the ground, if a lone occupant in basket were to fall, there would be no means to lower the lift and rescue them. Some models of aerial lifts can go as high as 185 ft. An individual hanging in a harness is at risk of suspension trauma where the leg straps impede blood return which can cause the blood to become toxic. Suspension trauma can ultimately lead to a blocked airway, cardiac arrest, brain damage, and death. Marcos reported the broken controls to the rental agency and a technician returned to the site and repaired the switch. The dierence between a near miss and an incident in these events was a single act by one person. Thank you Isaias, Jason, and Marcos for demonstrating why people are Manson’s most valuable asset. Jason Prohaska — Foreman — enjoying the sunny day and fresh air at the Mukilteo Ferry Terminal project in Seattle, WA.The bullgang crew, including Marcos Lozano, of the RM WHITE.Left to Right: Yery Robledo - Deckhand, Scott Moran - Boatman, Marcos Lozano – Deck Captain, Blake Chouest – Superintendent , Terry Roberts – Crane Operator, Chris Wrightson - Boatman, Damien Dawson - Deckhand, Guadalupe Cesar Silva – Deck Captain, Ezzard “Bo” Arrington - Deckhand, Brian Buehler – Deck Captain, James Robinson – Crane Operator, Robert Ricardy – WelderPHOTO CREDIT | ZACH CHESTER— GULF & EAST COAST DREDGING, OPERATIONS MANAGERPHOTO CREDIT | ERIK DOLMSETH—SUPERINTENDENT16Manson Navigator | Fall 2020

PHOTO CREDIT | JUSTIN ENJO—FIELD ENGINEEREddie Heredia aligning pile on the VALKYRIE at the Pier 8 R Wharf Construction project at Naval Base San Diego in California.17 Fall 2020 | Manson Navigator

| TEAM FOCUS — IT |If there is one department that should get major kudos for helping the rest of Manson make it through the chaos that has ensued in 2020, it would be the IT department. Although helping Manson employees with their IT needs has always been a part of the job description, the group of 13 techs have elded numerous new challenges throughout the year, not least of which was enabling us to continue doing our jobs while battling through the changes brought on with the COVID-19 pandemic. For some positions, the nature of work will always be hands on and in person, but going to work means a whole dierent thing these days for many workers. Thanks to IT Director Joe Hussin and his team, it now means that many Manson employees can work from pretty much anywhere. But in Joe’s mind, the transition is all just part of a day’s job.“Although Manson has not always been into the idea of telecommuting, over the years we have put platforms in place so that we could one day make the transition easily,” Joe explains. “When suddenly everyone needed to be able to work from home, it was really just a matter of enabling the systems we had already put in place.”According to Danny Coleman, senior network engineer, looking ahead at the industry and identifying future needs to make sure we can be ready for them is essentially the name of the game in their department. “Often times those changes are driven from end users or departments, and sometimes it is us looking at how technology is changing,” Danny says. “Either might require changes to the platforms we use, so we like to build our systems in a way that we’re able to eventually incorporate those changes.”Something the department often talks about is that there are a lot of very intelligent people throughout Manson who need the right tools to do a great job. “Our goal in IT is to enable them to do what they do as easily, transparently, and securely as possible,” he says.As needs evolve, the department is set up in a way that systems can be modied to suit Manson’s changing environment. Paul Massee, database administrator, is responsible for building several of the systems used throughout Manson, including the purchasing system, Manson Learning System, and others. “Some [of the tools I’ve built] have outlived their usefulness and are now defunct, others are still in use, and some, like the Learning System, have evolved from a simple safety training database to more trainings across the entire Company,” Paul says. Often out-of-the-box solutions, while popular and usable, don’t always cover all the needs of the end-users. Paul sees his role as lling the gaps of the tools and applications that Manson employees may be missing. He is also part of a major push to streamline and integrate systems across the Company. Nik Xaylavong, systems administrator, says that with so many of the systems relying on each other to work, there are many intricacies to continually maintain. “If one thing goes wrong, then all of those systems won’t talk to each other and people won’t be able to get the job done.”A running theme, no matter who you speak to in the IT Department, is that they see other Manson employees as their customers. “We all work for the same company, but we strive to let sta know that the other employees in the company are our customers,” says Bob St. Joseph, senior IT help desk technician. “We want to have our customers – the end users – able to do their job as easily as possible, with as few interruptions as possible, using the technology that Manson provides them.”Bob, along with Esther Chung, and Jonathan Knight, IT help desk supervisor and coordinator respectively, consider themselves the front line of the IT department, elding help desk tickets and monitoring problems and requests. “We’re basically the rst point of contact, and here for more of the everyday issues that people come up with,” he explains. A big part of that is also ensuring safety, security, and compliance. “A lot of times, people don’t always understand why there are restrictions, but safety and security are paramount,” he explains. There are government requirements that must be met, which requires continually updating security measures and monitoring the software in use on Manson’s servers. Businesses are a lot dierent than individuals when it comes to software licensing, and Esther—who is primarily responsible for monitoring software licensing, tracking, compliance, and auditing—helps tech users navigate the software system to nd the right license. “If someone has a single-user license on their computer and then we get audited, we could end up getting ned ten times what it would have cost to just purchase the correct license in the rst place.”In the end, when everything is running smoothly, you don’t really hear much from IT. And, in a sense that’s good, but in order to keep work functioning, IT is a critical part of what everyone at Manson does, Nik says. “Like a carpenter needs a hammer and measuring tape, our engineers need software,” he says. “We want to have our customers – the end users – able to do their job as easily as possible, with as few interruptions as possible, using the technology that Manson provides them.”“ “BEHIND THE SCENES WITH THEIT DEPARTMENTWRITTEN BY | JIMMIE COLLINS—PROPOSAL & MARKETING MANAGER18Manson Navigator | Fall 2020

Congratulations to Vice President of Equipment, Shawn Hillis, on his retirement after 42 years with Manson! Shawn is a second generation Manson employee and the 10th Hillis to be associated with Manson. Shawn began his career in October 1978, learning the ins and outs of vessel maintenance and operations. In June of the following year he was assigned to the newly-christened JEFFREY M to tow the cutter suction dredge HUSKY II to Alaska. Regarding that rst trip Shawn recalls, “It was a great experience. I was 19-years-old, and we took that spanking new red-and-white boat up the Inland Passage – one of the most beautiful trips in the world.” Over the years, Shawn has worked on nearly every derrick, dredge, and tug in Manson’s eet, working up and down the West Coast, including a trip to Cedros Island, Mexico. He also spent time aboard the hopper dredges NEWPORT and WESTPORT learning systems for hydrographic surveying. Shawn was promoted to Vice President of Equipment in 2006, and he has been instrumental in keeping Manson’s rigs in shipshape condition, implementing a vigorous maintenance program, and continually leading upgrade initiatives with the best available and environmentally conscious technology.Thank you, Shawn, for all your hard work and service to Manson. For those who have worked in dredging within Manson’s Gulf & East Coast team over the last ve decades, just about everyone knows the name “Captain Ronney.” Since 1969, he’s been logging 12 hour days on a cutter suction dredge somewhere in the Gulf and East Coast of the United States. In addition to owning his own dredge company, he has worked for Goodloe, Southern, TL James, Great Lakes, Devcon, Orion, Weeks, Inland, and Manson. In addition to being the Captain of Manson’s dredge LEONARD J and dredge BECHTOLT, he captained the dredge PONTCHARTRAIN, the CAPTAIN FRANK, the GD MORGAN, and the VENTURE (all 27 and 30 inch dredges.) Captain Ronney has more remarkable, startling, and gut wrenching stories than anyone I’ve ever met. And if you spend enough time with him, he will also gift you with unlimited candid opinions. He will tell you what companies in the industry have the best equipment and worst equipment. He will tell you which companies are dangerous and safe, ethical and unethical. He will tell you who the owners and supervisors are, their personalities, and how they are as people. One thing Captain Ronney has told me many times without hesitating, is that there is no dredging company that treats its people as well as Manson.Captain Ronney was and always will be “old school.” He hates paperwork. And tells the unltered truth unconditionally. Even retired, he’ll remain widely known and talked about for years to come. A natural born leader who worked his crews hard and commanded respect, but was also a mentor (and even father gure) to literally hundreds of young dredge hands through the years. We will miss him greatly.After a 46-year career in the marine construction industry with his last 10 years at Manson, Robert LeBlanc retired on May 15, 2020. Robert worked out of the Houma, LA, oce with the oshore group starting as the oshore manager and moving up to vice president of oshore construction. His experience in the oil and gas construction industry prior to joining Manson proved invaluable in building strategies and plans to best apply Manson assets and expertise. Robert excelled in his ability to see and pursue relationships that weren’t obvious because he left no stone unturned and no link unfollowed. Robert was part of the family in Houma as he continued to make relations with customers, vendors, and employees. Robert enjoyed collecting historical oil and gas les and sharing articles and old photos with his colleagues. In his free time, Robert liked to spend time working on with his classic Ford Mustang. His love for classic cars includes traveling the coast to show o his car and checking out those of other collectors. We wish him well during the next journey in his life, as he travels and spends time with his wife, children, and grandchildren. We will miss his team spirit and good nature. Please join us in wishing Robert well in his retirement. | MANSON PEOPLE — RETIREES |RONNEY SNIDERROBERT LEBLANCSHAWN HILLISWRITTEN BY | SARAH NESS—PROPOSAL & ESTIMATING COORDINATORWRITTEN BY | ZACH CHESTER—GULF & EAST COAST DREDGING, OPERATIONS MANAGERWRITTEN BY | JENNIFER JACUZZO—HOUMA, LA, OFFICE MANAGER 19 Fall 2020 | Manson Navigator

CELEBRATING5| MANSON PEOPLE — MILESTONES |BYRON GARCIA DAVID SWANNER JR. FORREST PRICE II GERARDO ALVAREZ LUIS A. ZUNIGA MEJIA YERY ROBLEDO AARON DAIGH ATHANASIOS VORVOLAKOS BENNETT PARKER DALE SWEENEY DOUGLAS LOWE EDWIN SHERMAN GLENDON GEORGE JEFFREY PAUP JONATHAN MACIEL JOSHUA HALL KELLY DIETRICH KENNETH LYNN LAURA VALDEZ LUKE GINDLESPERGER NATALIE ATWOOD NATHAN CARBAJAL PHILIP TYER PHILLIP SALCEDA RANDY WILLIAMS SAMANTHIA EMMONS STEVEN HENLINE TIMOTHY DANIELS JUAN ENVERGA PEDRO HERNANDEZ TIMOTHY HORN AUGUST LAMEN CONNER LONG KYLE GARDNER TRINA MCNARY ALEX SCHWIGER BRANT SIMPSON CHRISTOPHER MCKINSEY COY MCCUISTION DANA GRINDSTAFF MICHAEL GARBOWSKI PATRICK SULLIVAN PAULA SHOUDY-ROBERTS RANDY MINCKS RYAN STEWART SEAN RAY CHARLES GRANGER COREY BABIN FULTON BLANCHARD JR. GEORGE SWINDEL IRA MATHERNE JERRY MAYO RAY MARTINEZ CHARLES ESCOFFON DAVID FRENCH J.C. GAMBLE JR. JAMES FOWLER KEVIN WILLIAMS LARRY DAVIS NATHANIEL VAZQUEZ-PILLAR RAYMOND GIVAN BRADLEY PETERSEN BRIAN SAUCK CHARLES GATLIN DANIEL MAKALE DAVID CRUZ GEORGE ATKINSON ISMAEL MARTINEZ JACK FERNANDEZ JAMES DAVIS JEREMY COOK JUSTIN ENJO NATHEN MARTINEZ RAYMOND ROMERO STEVEN MARQUEZ WILLIAM KING MATTHEW LEHMANN ESTHER CHUNG JOSEPH QUINN NATHANIAL ROLLER RACHEL ODELL BRANDT STAGNI CONDER BOOKER KENNETH HOLSTON MARIO IBANEZ ANTHONY MAHR BARRIE WHITE BRIAN WALKER DAVID HOWARD HOWARD MILLER IRA RICKS JERRY WHITE KARL LAMOREAUX MICHAEL WILLIS MICHAEL WARWICK RUSSELL SKELLIE SAMUEL MILLER ULYSSES VINARTA JR WILLIAM HOUSE WILLIAM RICKS KEVIN CANALES PAUL KARCSAY ALBERT NAHOOPII MELINDA MARTIROSIAN STEVEN KIEL EARL JOHNSON JULIE RHOADS ROBERT BONVECHIO STANLEY MADISON BENNY COLANGELI KENT IVY KYLE RICH RICARDO SANCHEZ AMADO SHUCK HAROLD MILES III RAYMUNDO GALLARDO RUSSELL WOODRUFF 1530252010MILESTONES20Manson Navigator | Fall 2020

| DEPARTMENT FEATURE — MANSON LEARNING NETWORK |MURMURATIONWeird word, amazing sight. It’s like an avian Pink Floyd laser show. If you don’t know what a murmuration is check out this Dutch video (scan the QR code below with your phone’s camera). So how do thousands or tens of thousands of birds – starlings, actually – manage to y so precisely without causing mid-air mayhem? It’s not group telepathy, or biomagnetism, or any kind of vocal communication – these ocks are surprisingly quiet. Actually, it’s a much simpler explanation: an individual starling pays relentless attention to the six or seven birds closest to it, giving and receiving signals that ne-tune individual behavior while simultaneously adapting to the larger group behavior. Obviously, such coordination requires all the members to understand the signals and the responses. It’s kind of a group “neural network.” And when a ock is networked like that, it’s capable of amazing feats.A MANSON LEARNING NETWORKFor all of its rich history, Manson has been a company that learns, adapts, and achieves in the face of challenge and change. How else could the company have thrived for so long? But, if this year, 2020, has taught us anything, it’s that Manson needs to be even smarter and more adaptable than ever to keep pace with the velocity of change, expected and unexpected. It’s a credit to Manson leadership that they foresaw this need and this year began creating the Manson Learning Network. Though it will take some time to get all the components in place, ultimately the MLN will serve as that “neural network” to establish the knowledge and skill pathways that promote a Manson … murmuration.I joined Manson in March this year to lead development of the MLN. For more years than I’m willing to admit, I’ve been helping organizations learn, perform, and excel. I’ve enjoyed devising solutions to a wide-range of organizational learning problems in several business sectors including defense, construction, environmental, and education. Now I’m eager to apply those experiences to the learning programs here at Manson. But the real strength on the MLN team will come from some familiar and talented long-time Manson employees. Dwight Henson has been developing training and teaching rigging at Manson for nine years, and now will focus his skills in instructional technology development. Complementing the technology side, after 14 years, Carey Shannon has moved from her role as safety specialist and EHS trainer into a broader role as MLN curriculum developer and trainer. Together this team has already begun to impact our collective corporate knowledge with their creation of the Safety Management System (SMS) Orientation Training for our hopper dredge crews, the COVID-19 Return to Work Training, and rolling out soon will be Cybersecurity Training and revitalized Manson University mini-modules.EMPOWERING PEOPLE TO PEAK PERFORMANCEThe MLN is guided by four essential values ensuring that it lives up to its mission statement: empowering people to peak performance. The essence of these values drive us to achieve three goals. First, Manson’s people are the focal point, and our future system will serve their professional development while inspiring their personal growth. Second, all of the MLN’s learning programs will strive for connection to the jobs we do; creating immediate relevance and consistent reinforcement for a successful learning process. And third, recognizing and capitalizing on the fact that learning can happen in innite ways, the MLN will constantly seek new and practical means to learn as individuals and groups to create a Manson learning network.COMING SOONThis year has forced a lot of change on our Company. But if you’ve noticed, change these days seems to be the rule rather than the exception. As a company, one of our critical learning objectives is how to be great at adapting to change. In 2021, the MLN will bring change to the ways we learn at Manson. We will shift to learning from “mini-modules” versus bulky classes, we will focus on performance improvement not just knowing stu, and we will leverage an array of learning technologies in a way that does not create barriers, but enhances learning.Please check in with us regularly as we get established and as we grow. You can nd many resources now on our SharePoint site, and many more to come in the future. We’d also like to hear from you: what are your needs, your ideas, your past experiences with great learning? Let’s talk, and let’s work together to drive peak performance.CROWD-BASED LEARNING: LESSONS FROM THE FLOCKTwo heads are better than one, they say. And, as the starlings’ murmuration show, thousands of heads working together can do stunning things. In a way, that’s our mission at the Manson Learning Network: bringing all of our heads together to do stunning things. We invite you to participate in Manson learning events, and even to help create them. Every one of us has something to oer to the learning enterprise, like the starling ocks, so please share your ideas. We’re looking forward to ying alongside you.THE MANSON LEARNING NETWORKWRITTEN BY | THOMAS BARRETT, Ph.D.—LEARNING & DEVELOPMENT DIRECTORSCAN FOR A COOL VIDEO.21 Fall 2020 | Manson Navigator

SUBMITTED BY | DANIEL NIELSEN—PILE DRIVING FOREMANThe VASA driving pile at the Blount Island Marine Terminal project in Jacksonville, FL.22Manson Navigator | Fall 2020

Our stories, told here.SOUTHERN CALIFORNIA340 Golden Shore, Suite 310Long Beach, California 90802p: 562.983.2340EAST COAST REGION5985 Richard Street, Suite 1Jacksonville, Florida 32216p: 904.821.0211 NORTHERN CALIFORNIA1401 Marina Way South, Suite 330Richmond, California 94804p: 510.232.6319GULF REGION392 Old Bayou Dularge RoadHouma, Louisiana 70363p: 985.580.1900 PACIFIC NORTHWEST (HQ) 5209 E. Marginal Way SouthSeattle, Washington 98134p: 206.762.0850 Join the conversation at linkedin.com/company/manson-construction-co.™