Return to flip book view

Super Sucker has the largest and most advanced fleet it has ever deployed, with a selection best suited to serve your ongoing construction projects. Accurate job assessments are utilized to assign the right equipment to get the work done safely and eciently, and we can also facilitate multiple pieces of equipment for deeper cost savings opportunities.Super Sucker Coring technology is a significant cost savings alternative to common repair methods which often require large “open” excavations. Our coring techniques and equipment allow subsurface maintenance and other municipal works projects to be conducted through small, precise openings cut into the surface of roadways or sidewalks. Subsequent hole excavation is then quickly accomplished by Super Sucker’s extensive fleet of hydrovacs.With 10 years of coring experience we’ve performed over 10,000 core removals and reinstated all of them without failure. You can rest assured that our crews will get the job done right every time.THE RIGHT TOOLS.WE CUT COSTS, NOT CORNERS!

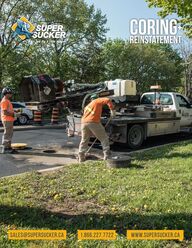

Overhead view of crew cutting cores.EXTRACTION: The core is then removed from the road or sidewalk and set aside to be reused during reinstatement.HYDROVAC EXCAVATION:Super Sucker hydrovacs are used to safely expose utilities for repairs, inspections or additional work.• Less trac disruption.• Standard road cuts take much longer to repair.• Drivable surface in as little as 30 minutes• Save over 50% in additional site restoration costs.• Reduced pollution, environmentally friendly.• Less excavation waste.• No open pit liability issues.• All repair work is easily accessed.• No loos of surface integrity (single wheel load: 50,000 lbs.)FASTER CLEANER SAFERCORING: The coring truck sets up to cut a 12”, 18”, or 24” diameter hole up to 22” deep. This equipment easily manages precision cuts through concrete or asphalt.STEP ONE: STEP TWO: STEP THREE:

RE-INSTATEMENT: When the task is completed, the hole is backfilled and the core is reinstated with a bonding compound that ensures a flush and level fit.SITE RE-OPENING: The coring area is fully restored to its original condition in as little 30 minutes.Coring area is kept clean during each step of the process.A backfilled double core anode pit ready for reinstatmentTop view of 18” coring bit.Coring crews working safely.STEP FOUR: STEP FIVE:

Fully trained and certified sta ensure superior service. We have many crews with full knowledge and understanding of the requirements specific to your industry – whether it’s construction, environmental, industrial, gas, hydro, or telecommunications.• Non - Destructive Vacuum Excavation Orientation • OHSA, WHMIS, AODA, First Aid • Trac Control Book 7 • Client-specific Policies + Procedures • Electrical Safety + Awareness • Fall Protection • Confined Space Awareness (Rescue) • Certificate of Insurance • WSIB Clearance Certificate • Employee Training Records • Super Sucker Corporate Policies• WHMIS Certificate(s) • Corporate Health + Safety StatementTHE RIGHT PEOPLE.DOCUMENTATIONTRAINING

You demand it and employees depend on it.At Super Sucker it’s always our top priority.Super Sucker provides significant value on projects that require a variety of dierent services. From subsurface utility engineering (SUE) projects, to major infrastructure upgrades and maintenance, our diverse fleet options allow us to assign the equipment needed to generate low budgetary requirements without compromising on safety or eciency. THE RIGHT CALL.LOcations across ontarioserious about safety.to serve you better.www.supersucker.ca905.297.4695hamiltonflamboroughmississauganewmarketlondonNIAGARAcambridge