Return to flip book view

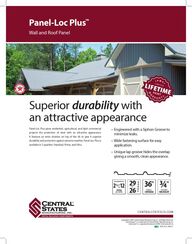

Panel-Loc Plus™Wall and Roof PanelCENTRALSTATESCO.COMFLYR_PLP_240412• Engineered with a Siphon Groove to minimize leaks.• Wide fastening surface for easy application.• Unique lap groove hides the overlap giving a smooth, clean appearance.Panel-Loc Plus gives residential, agricultural, and light commercial projects the protection of steel with an attractive appearance. It features an extra striation on top of the rib to give it superior durability and protection against extreme weather. Panel-Loc Plus is available in 3 qualities: Standard, Prime, and Ultra.Superior durability withan attractive appearance2926GAUGE36"OVERALLCOVERAGE¾"MAXIMUMRIB HEIGHT2 ½ : 12PITCHAND ABOVERECOMMENDEDECORCopyright © 2024, Central States Manufacturing, Inc., All Rights Reserved.CentralGuard® is a trademark of Central States® Manufacturing, Inc.Galvalume® is a registered trademark of BIEC International, Inc. Message

Find more information atcentralstatesco.comGAUGE Ultra 26 ga. | Prime 29 ga.STEEL THICKNESS Ultra 0.0185" | Prime 0.0150"PAINT THICKNESS Top coat paint: .70 mil Top coat primer: .30 mil Bottom coat backer: .35 mil Bottom coat primer: .35 milTOTAL THICKNESS Ultra 0.0202" | Prime 0.0167"RUST PROTECTANT SUBSTRATE Galvalume® AZ50STEEL STRENGTH 80,000 PSI minPAINT SYSTEM SMPWARRANTY Lifetime limited paint adhesion 30-yr. chalk and fade 50-yr. Galvalume perforationTESTING TAS 100-95 Wind Driven Rain Test TAS 125-03 Uplift Resistance Test, 29 ga. Prime only ASTM-E455 Diaphragm Shear Standard Test, 26 ga. ASTM-E455 Diaphragm Shear Standard Test, 29 ga.APPROVALS UL2218 UL Approval, Impact Resistance, Class 4 UL580 UL Approval, Uplift Resistance, Class 90 UL790 UL Approval, Fire Resistance, Class A RC-325 Texas Windstorm Approval, 29 ga. Over Wood Purlins RC-326 Texas Windstorm Approval, 29 ga. Over Decking FL14026 Florida Approval, Roof Panel Over ⁄" Plywood (HVHZ, Miami-Dade Approved) FL14026 Florida Approval, Roof Panel Over ⁄" Plywood (NON-HVHZ) FL14026 Florida Approval, Panel Over 2x4’s (NON-HVHZ))MINIMUMSPECIFICATIONSFOR ULTRA AND PRIMEPAINTED PANELSTESTING & APPROVALSChoose CentralGuard®for the best protection anda lifetime warranty.CentralGuard is our specic combination of everything that goes into making the highest-quality metal panels. Available on our Prime and Ultra panels, the CentralGuard name is a guarantee that you have the best protection and a lifetime paint warranty.Choose CentralGuard for the perfect balance of fade protection, rust blocking, and dent resistance. STANDARDPRIME ULTR ACentralGuard CentralGuardFADE PROTECTIONPaint Warranty 40-YEARLIFETIME LIFETIMEPaint Thickness THICK .90 milTHICKER 1.0 mil THICKER 1.0 milFade Warranty 30-YEAR30-YEAR 30-YEARFade ProtectionP PP PPRUST BLOCKINGAdvanced Rust Blocking –P PPerforation Warranty –50-YEAR 50-YEARSubstrate Thickness 1.12 mil1.60 mil 1.60 milDENT RESISTANCEAdvanced Dent Resistance –P PPSteel Thickness THINTHICK THICKESTSteel Gauge 29 ga.29 ga. 26 ga.OUR BEST SELLER!Panel-Loc Plus features UL2218 approval for impact resistance and may qualify for a homeowners insurance discount. See your local insurance agent for qualications.Siphon GroovePanel-Loc Plus has two vertical edges, the overlap and the sidelap. The sidelap edge has a specic bend in the last major rib, called a siphon groove. When the overlap edge is installed on top of the sidelap edge, it creates an air gap that prevents water from wicking under the panel. Panels should be installed with the overlap facing away from the prevailing wind. SIDELAPOVERLAPPREVAILING WINDSOVERLAPSiphon GrooveSIDELAP

GUID_PROD_PLP-CL_240415D CPanel-Loc Plus™Product GuideHELPFUL INFORMATION ON PANELS, TRIMS, GUTTERS AND ACCESSORIES36" COVERAGE9"¾"This guide includesdetails for 5V.

CENTRAL STATES MANUFACTURING, INC.Effective 05/2022 • Information subject to change 3Information in this catalog may vary by plant location.Please call your salesperson to verify product availability.NOTICE: The application and detail drawings in this manual are strictly for illustration purposes and may not be applicable to all building designs or product installations. Projects should conform to local building codes. Central States Manufacturing is not responsible for the performance of the material if it is not installed correctly.Information contained in this booklet was in eect at the time of publication and is subject to change without notice.Panel-Loc Plus Panel Codes, Fastener Spacing, Section Properties 4-55V Panel Codes, Fastener Spacing 6Care and Handling, Siphon Groove 7-8Converting Pitch to Degree 9Square Conversions 10Gauge and Color Codes 11Roof Trims 12-13Wall Trims 13-14Sot/Fascia 15Accessories 16-17Sliding Doors 18-20WARRANTIESWarranties are available in paper format and downloadable from our website. After the job is complete, ll out a warranty with your contractor/installer details and the Central States order number. Give the warranty to the building owner to keep for their records. Optional warranty registration is available online.Learn more at centralstatesco.com/warrantiesINDEX

CENTRAL STATES MANUFACTURING, INC.Effective 05/2022 • Information subject to change 4PANEL-LOC PLUSPANEL PROFILE TYPE CODEPanel-Loc Plus™ Ultra SMP PP6(color)Panel-Loc Plus™ Prime SMP/FEVE* PP9(color)Panel-Loc Plus™ Prime SMP G90 PP9(color)G90Panel-Loc Plus™ Standard PP9(color)STPanel-Loc Plus™ Thrifty SMP* PP6(color)THPanel-Loc Plus is available in Ultra 26 gauge, Prime 29 gauge, and Standard 29 gauge; in painted or bare Galvalume®. Ultra and Prime panels feature CentralGuard® protection and a lifetime paint warranty. Standard panels feature a 40-year paint warranty. CentralGuard is our specic combination of everything that goes into making the highest-quality metal panels. Choose CentralGuard for the perfect balance of fade protection, rust blocking, and dent resistance. Bare (unpainted) Galvalume® and galvanized panels from Central States have an acrylic coating which eliminates using oils during manufacturing and eliminates ngerprinting and foot marking during installation.The minimum roof slope for the ¾" Panel-Loc Plus™ is 2 ½:12. If slopes less than 3:12 are needed, International Building Code (IBC) allows a sealant tape to be used on the laps of the panel.FASTENER SPACING9"9"Fastener pattern at panel termination (Eave, endlap, valley, ridge, high eave)Fastener pattern at interior of panel9"9"Follow the suggested fastener patterns below for interior or panel termination. Screws may be placed in either the at or the rib. In the overlap condition, avoid using fasteners in the major rib as this may damage the siphon groove.PANEL CODES* Longer lead times may apply. *FEVE- Flourinated Polymer Paint System

CENTRAL STATES MANUFACTURING, INC.Effective 05/2022 • Information subject to change 5SECTION PROPERTIES - PANEL-LOC PLUS36" WIDE, PANELLOC PLUS™ PANELSection properties and allowables are calculated in accordance with 1996 AISI Specications and 1999 AISI Supplement No. 1. I +/- is for deection determination. S +/- is for bending determination. Ma is allowable bending moment. All values are for one foot of panel width. These loads are for panel strength. Frames, purlins, fasteners and all supports must be designed to resist all loads imposed on the panel. Allowable outward loads based on stress have been increased by 33.33% for wind uplift. Allowable loads for deection are based on deection limitation of span/180 or span/240. For roof panels, self weight of the panel has to be deducted from the allowable inward load to arrive at the actual "live load" carrying capacity of the panel. Minimum bearing length must be checked. Minimum deliverable bare steel thickness should not be less than 0.95 of design thickness.Theoretical allowable loads are based on uniform span lengths. LL (S) is allowable live load based on stress limitation. LL (D) is allowable live load based on deection limitation of L/180 or L/240. WL is allowable wind load and has been increased by 33.33%.SINGLE SPAN CONDITIONTHEORETICAL ALLOWABLE LIVE & WIND LOADSTWO SPAN CONDITIONTHREE OR MORE SPAN CONDITIONSpan (feet)22.533.544.556WL(psf)127.781.756.741.731.925.220.414.2LL (S)(psf)108.269.348.135.327.121.417.312.0LL (D) L/180(psf)108.261.535.622.415.010.67.74.5LL (D) L/240(psf)90.146.226.716.811.37.95.83.329 Gauge & 80 ksi 26 Gauge & 80 ksiWL(psf)157.9101.170.251.639.531.225.317.5LL (S)(psf)131.984.458.643.133.026.121.114.7LL (D) L/180(psf)131.974.643.227.218.212.89.35.4LL (D) L/240(psf)109.355.932.420.413.79.67.04.0Span (feet)22.533.544.556WL(psf)121.077.553.839.530.323.919.413.4LL (S)(psf)96.061.442.731.324.019.015.410.7LL (D) L/180(psf)96.061.442.729.219.613.710.05.8LL (D) L/240(psf)96.060.134.821.914.710.37.54.329 Gauge & 80 ksi 26 Gauge & 80 ksiWL(psf)175.4112.378.057.343.934.628.119.5LL (S)(psf)118.776.052.838.829.723.519.013.2LL (D) L/180(psf)118.776.052.835.423.716.712.17.0LL (D) L/240(psf)118.772.842.226.517.812.59.15.3Span (feet)22.533.544.556WL(psf)168.1107.674.754.942.033.226.918.7LL (S)(psf)112.171.849.836.628.022.217.912.5LL (D) L/180(psf)112.171.849.836.628.019.914.58.4LL (D) L/240(psf)112.171.849.831.721.314.910.96.329 Gauge & 80 ksi 26 Gauge & 80 ksiWL(psf)204.9131.191.166.951.240.532.822.8LL (S)(psf)138.788.861.645.334.727.422.215.4LL (D) L/180(psf)138.788.861.645.334.424.117.610.2LL (D) L/240(psf)138.788.861.138.525.818.113.27.6Ixxin4/ft0.00930.0073Sxxin3/ft0.01980.0160Main.kips/ft0.71230.5760Ixxin4/ft0.01330.0110Sxxin3/ft0.02200.0181Main.kips/ft0.79130.6493Gauge26 ULTRA29 PRIMEThickness(inches)0.01850.0150Weight(psf)0.8660.704Yield Stress(ksi)80.080.0Top in Compression(Positive Bending)Bottom in Compression(Negative Bending)

CENTRAL STATES MANUFACTURING, INC.Effective 05/2022 • Information subject to change 65V™PANEL PROFILE TYPE CODE5V™ 26 Ga. Galvalume® 5V6GL5V™ 29 Ga. Galvalume® 5V9GL5V™ 29 Ga. Galvanized G90 5V9ZNG905V is available in 26 ga. and 29 ga bare Galvalume, or 29 ga. bare galvanized G90. Bare (unpainted) Galvalume® and galvanized panels from Central States have an acrylic coating which eliminates using oils during manufacturing and eliminates ngerprinting and foot marking during installation.Galvalume® features a 25-year AZ55 substrate warranty, but is not warranted for uniformity in appearance, whether it be color, sheen, or spangle. If the project requires a uniform appearance, please choose a painted product of a dierent prole.The minimum roof slope for 5V is 3:12. No load table available. Install 5V over solid decking with 30 lb. felt paper or equivalent.FASTENER SPACINGFastener pattern at panel termination (Eave, endlap, valley, ridge)Fastener pattern at interior of panelFollow the suggested fastener patterns below for interior or panel termination. PANEL CODESGalvalume® is a registered trademark of BIEC International, Inc..

CENTRAL STATES MANUFACTURING, INC.Effective 05/2022 • Information subject to change 7Deliveries will be made using a 65' tractor/trailer weighing approximately 80,000 lbs. It is imperative that all delivery locations be accessible by a vehicle of this size. Our drivers have the authority to refuse delivery to any location they see as unsafe or inaccessible. The customer is responsible for any charges incurred if truck is detained for any reason. The customer is responsible for unloading all trucks. Any damage that occurs at this point is the customer’s responsibility. There must be equipment available to unload the truck. Moett deliveries require at least one person to assist with unloading.STAGEGalvalume® steel panels have a good service life when exposed to normal weather conditions; however, to protect the appearance of panels and trims from damage, there are a few simple precautions that can be taken. The steel panels are subject to stain when water sits upon, or becomes trapped between the sheets. If the Galvalume® panels are to be stored for any period of time, they should be stored only in a dry place, preferably under a roof. Stand panels on end and fan them out at the bottom to provide air circulation and moisture run o. If space does not allow this, the panels should be separated, blocked o of the oor at least 12 inches to allow air ow, and stored at an incline to encourage drainage. The panels should then be covered, yet still have good air ow through the sheets to prevent condensation. Do not use a plastic cover, as this may cause the panels to sweat or condensation to occur.STORAGEFailure to follow these steps may result in wet storage stains and premature rusting. The manufacturers warranty will be void at this time, and the manufacturer will not be responsible.HANDLINGWhen unloading panels, extreme caution must be employed. Care needs to be used when unloading panels with a forklift. Panel edges and underside paint may become damaged if the forklift driver does not use caution. Once at the job site, care must be taken in order to protect the painted surface. When unbundling the panels, never drag them across the surface of one another. This may cause scratches across the underneath panels. It is recommended that the panels be “rolled” o the top of the bundle to prevent scratching. Never lift panels by the ends, instead lift the panels longitudinally and carry vertically.Panel edges are very sharp, therefore, safety equipment should be worn by all workers handling the material.DELIVERYCARE AND HANDLINGStrippable lm on Textured panels and trim must be removed within 30 days of manufacture date. Strippable that is left on for more than 30 days may be hard to peel o and is not a reason for a refund or replacement from the manufacturer.CAUTION

CENTRAL STATES MANUFACTURING, INC.Effective 05/2022 • Information subject to change 8CARE AND HANDLINGCUTTINGA portable eld shear is the ideal method for cutting panels. Nibblers or a power shear may also be used. Although we do not recommend it, if you decide to cut with a saw, it is very important that the panels be turned upside down during cutting so that hot shavings do not come in contact with the painted surface. Make sure all adjacent panels are covered so that shavings are not imbedded in these panels. If metal shavings become imbedded in the paint surface, they will quickly rust. To avoid this, panels should be thoroughly wiped of all lings on both sides of the panel. Failure to comply with the recommended cutting procedures releases the manufacturer of any responsibility.DRILLINGPanels should not be drilled while stacked. This will cause shavings that will become imbedded in the paint surface.Shavings created by saw cutting or drillingmay cause the panel to rust and will void warranties in aected areas.CAUTIONPREVAILINGWINDSSIDELAPOVERLAPOVERLAPSIPHON GROOVESIDELAPDo not damage the siphon groove by using a stitch screw on top of the major rib or clog it with butyl tape.Panel-Loc Plus has two vertical edges, the overlap and the sidelap. The sidelap edge has a specic bend in the last major rib, called a siphon groove. When the overlap edge is installed on top of the sidelap edge, it creates an air gap that prevents water from wicking under the panel. Panels should be installed with the overlap facing away from the prevailing wind. SIPHON GROOVE

CENTRAL STATES MANUFACTURING, INC.Effective 05/2022 • Information subject to change 9CONVERTING PITCH TO DEGREE135°1:12PITCH2:12PITCH3:12PITCH4:12PITCH5:12PITCH6:12PITCH7:12PITCH8:12PITCH9:12PITCH10:12PITCH11:12PITCH12:12PITCH13:12PITCH14:12PITCH15:12PITCH16:12PITCH17:12PITCH18:12PITCH1:12PITCH175° 171° 166° 162° 158° 155° 151° 148° 145° 142° 140° 137° 135° 133° 132° 130° 128°2:12PITCH175° 175° 171° 167° 163° 159° 156° 153° 150° 147° 144° 142° 140° 138° 136° 135° 133°3:12PITCH171° 175° 176° 171° 167° 164° 160° 157° 154° 152° 149° 147° 145° 143° 141° 139° 138°4:12PITCH166° 171° 176° 176° 172° 168° 165° 162° 159° 156° 153° 151° 149° 147° 145° 144° 142°5:12PITCH162° 167° 171° 176° 176° 172° 169° 166° 163° 160° 158° 155° 153° 151° 149° 148° 146°6:12PITCH158° 163° 167° 172° 176° 176° 173° 170° 167° 164° 162° 159° 157° 155° 153° 152° 150°7:12PITCH155° 159° 164° 168° 172° 176° 177° 173° 170° 168° 165° 163° 161° 159° 157° 155° 154°8:12PITCH151° 156° 160° 165° 169° 173° 177° 177° 174° 171° 169° 166° 164° 162° 161° 159° 157°9:12PITCH148° 153° 157° 162° 166° 170° 173° 177° 177° 174° 172° 170° 167° 166° 164° 162° 161°10:12PITCH145° 150° 154° 159° 163° 167° 170° 174° 177° 177° 175° 173° 170° 168° 167° 165° 163°11:12PITCH142° 147° 152° 156° 160° 164° 168° 171° 174° 177° 178° 175° 173° 171° 169° 168° 166°12:12PITCH140° 144° 149° 153° 158° 162° 165° 169° 172° 175° 178° 178° 176° 174° 172° 170° 169°LOWER ROOF PITCH INCHES OF RISE OVER 12" OF RUNUPPER ROOF PITCH INCHES OF RISE OVER 12" OF RUNTRANSITION TRIM180°170°160°150°140°130°120°110°100°90°80°70°60°50°40°30°20°10°0°Use these charts to calculate degrees when designing custom trim.Please specify pitch when ordering. 90°Upper Transition Trim3:1210:12154°Lower Transition Trim10:123:12154°Painted sidePainted sideFind the box that intersects your lower and upper roof pitches.If the intersection landsin the gray area, select aLower Transition trim.30°1:12PITCH2:12PITCH3:12PITCH4:12PITCH5:12PITCH6:12PITCH7:12PITCH8:12PITCH9:12PITCH10:12PITCH11:12PITCH12:12PITCH94° 99° 104° 108° 112° 116° 120° 123° 126° 129° 132° 135°173° 167° 160° 154° 148° 143° 138° 134° 130° 126° 123° 120°170° 161° 152° 143° 135° 127° 120° 113° 106° 100° 95° 90°SINGLE SLOPE PITCHES Fascia, Eave, Endwall, Tie-In, GutterDOUBLE SLOPE PITCHES Hip, ValleyRIDGE CAP

CENTRAL STATES MANUFACTURING, INC.Effective 05/2022 • Information subject to change 10COMMON RAFTER LENGTHS PEAK TO SIDEWALLRunning Feet12345678910111213141516171819202122232425262728293031323334351:12 Pitch1' 0"2' 1/8"3' 1/8"4' 1/8"5' 1/4"6' 1/4"7' 1/4"8' 3/8"9' 3/8"10' 3/8"11' 1/2"12' 1/2"13' 1/2"14' 5/8"15' 5/8"16' 5/8"17' 5/8"18' 3/4"19' 3/4"20' 7/8"21' 7/8"22' 7/8"23' 1"24' 1"25' 1"26' 1-1/8"27' 1-1/8"28' 1-1/8"29' 1-1/4"30' 1-1/4"31' 1-3/8"32' 1-3/8"33' 1-1/2"34' 1-1/2"35' 1-1/2"2:12 Pitch1' 1/8"2' 3/8"3' 1/2"4' 5/8"5' 7/8"6' 1"7' 1-1/8"8' 1-3/8"9' 1-1/2"10' 1-5/8"11' 1-7/8"12' 2"13' 2-1/8"14' 2-3/8"15' 2-1/2"16' 2-5/8"17' 2-7/8"18' 3"19' 3-1/8"20' 3-3/8"21' 3-1/2"22' 3-5/8"23' 3-3/4"24' 4"25' 4-1/8"26' 4-1/4"27' 4-1/2"28' 4-3/4"29' 4-7/8"30' 5"31' 5-1/8"32' 5-1/4"33' 5-1/2"34' 5-3/4"35' 5-7/8"3:12 Pitch1' 3/8"2' 3/4"3' 1-1/8"4' 1-1/2"5' 1-7/8"6' 2-1/4"7' 2-5/8"8'3"9' 3-3/8"10' 3-3/4"11' 4-1/8"12' 4-3/8"13' 4-3/4"14' 8-1/8"15' 5-1/2"16' 5-7/8"17' 6-1/4"18' 6-5/8"19' 7"20' 7-3/8"21' 7-3/4"22' 8-1/8"23' 8-1/2"24' 8-7/8"25' 9-1/4"26' 9-1/2"27' 9-7/8"28' 10-1/4"29' 10-5/8"30'11"31' 11-3/8"32' 11-3/4"34' 1/8"35' 1/2"36' 7/8"4:12 Pitch1' 5/8"2' 1-1/4"3' 2"4' 2-5/8"5' 3-1/4"6' 3-7/8"7' 4-1/2"8' 5-1/4"9' 5-7/8"10' 6-1/2"11' 7-1/8"12' 7-3/4"13' 8-1/2"14' 9-1/8"15' 9-3/4"16' 10-3/8"17' 11"18' 11-5/8"20' 3/8"21' 1"22' 1-5/8"23' 2-1/4"24' 3"25' 3-5/8"26' 4-1/4"27' 5"28' 5-5/8"29' 6-1/4"30' 6-7/8"31' 7-1/2"32' 8-1/8"33' 8-3/4"34' 9-3/8"35' 10"36' 10-5/8"5:12 Pitch1'1"2'2"3'3"4'4"5'5"6'6"7'7"8'8"9'9"10'10"11'11"13'0"14'1"15'2"16'3"17'4"18'5"19'6"20'7"21'8"22'9"23'10"24'11"26'0"27'1"28'2"29'3"30'4"31'5"32'6"33'7"34'8"35'9"36'10"37'11"6:12 Pitch1' 1-3/8"2' 2-7/8"3' 4-1/4"4' 5/8"5' 7-1/8"6' 8-1/2"7' 9-7/8"8' 11-3/8"10' 3/4"11' 2-1/8"12' 3-5/8"13' 5"14' 6-3/8"15' 7-7/8"16' 9-1/4"17' 10-5/8"19' 1/8"20' 1-1/2"21' 2-7/8"22' 4-3/8"23' 5-3/4"24' 7-1/8"25' 8-5/8"26' 10"27' 11-3/8"29' 3/4"30' 2-1/4"31' 3-3/4"32' 5-1/8"33' 6-1/2"34' 7-7/8"35' 9-1/436' 10-3/4"38' 1/4"39' 1-5/8"For 26 ga. and 29 ga. low rib panels there are 2 formulas; one for panels measured in inches and one for panels measured in feet. While the actual panel width is 38", there will only be 36" of coverage per panel. Squares are gured based on actual width. One square is equal to a panel 31.579 feet long. One square of metal will give you approximately 94.5 square feet of coverage. One square is equal to 14,400 square inches.38 (or width in inches) multiplied by length in inches multiplied by # of pieces divided by 14,40038" x 144" x 12 equals 4.56 squares of metal14,400Number of panels = 12Panel width = 38"Panel length = 144"Square inches = 14,400EXAMPLE USING INCHES:length in feet multiplied by # of piecesdivided by 31.579*12 x 12 31.579Number of panels = 12Panel width = 38"Panel length = 12'EXAMPLE USING FEET:equals 4.56 squares of metal*For 26ga. Thrifty Panel-Loc Plus or Panel-Loc, use 31.373 in place of 31.579.SQUARE CONVERSIONS

CENTRAL STATES MANUFACTURING, INC.Effective 05/2022 • Information subject to change 11HOW TO ORDER TRIM* Longer lead times may apply. ** Copper Metallic is Fluropon®. Galvalume® is a registered trademark of BIEC International, Inc..RCP 6 RR TRIM GAUGE COLOR CODE CODE CODE TRIM CODEEXAMPLE: Ridge Cap, 26 gauge, RusticRIDGE CAPRCP - Girth 13.75" 15⁄8"4"6 ¼"½" hempitch¾"PAINTSTEP 1:In CentralLink™, start by entering the Item ID. Item ID is made of the TRIM CODE, a GAUGE CODE, and a COLOR CODE. The TRIM CODE can be found with each drawing next to the trim's name. The GAUGE CODE and COLOR CODES are found below.STEP 2:Then type the number of pieces you needalong with the length in feet and inches.COLOR CODESGAUGE CODE26 629 9GAUGE CODES PANEL TRIMSMP GAUGE GAUGE CODEAlamo 29/26 29 AWBlack 29/26 29/26 BKBrilliant 29/26 29/26 BIBrown 29/26 29/26 BRBurgundy 29/26 29/26 BGBurnished Slate 29/26 29/26 BSCharcoal 29/26 29/26 CHColony 29 26 CGCopper Metallic** 29 29 CMCrimson 29/26 29/26 CRDesert 29 26 DSForest 29/26 29/26 DGGallery 29/26 29/26 GBGalvalume® 29/26 29/26 GLGalvanized 29 29 ZNGray 29/26 29/26 GAHawaiian 26 HBHunter 29/26 29/26 GRIvory 29 29 IVLight Stone 29/26 29/26 LSOcean 29/26 29 OBPewter 29 29 PGPolar 26 PWRustic 29/26 29/26 RRTan 29/26 29/26 TNTaupe 29/26 29/26 TA PANEL TRIMFLUROPON® GAUGE GAUGE CODEAntique Ivory 29 26 AIAsh 29 26 ASAutumn 29 26 AUBeige 29 26 BEBrandywine 29 26 BWBrite 29 26 BTBronze 29 26 BZClay 29 26 CLEvergreen 29 26 EVHartford Green 29 26 HGMatte Black 29 26 MBRoman 29 26 RBSand 29 26 SASmoke 29 26 SMTerratone 29 26 TETudor 29 26 TUTEXTURE PANEL TRIMSMP GAUGE GAUGE CODEBasil* 29 26 BAMineral* 29 26 MIOnyx* 29 26 OXRoma* 29 26 RMSienna* 29 26 SISumatra* 29 26 SULookupRCP6RREnter Item IDPieces10Feet12Inches2Description: 26, Rustic, Ridge Cap CentralLink order screen

CENTRAL STATES MANUFACTURING, INC.Effective 05/2022 • Information subject to change 12ROOF TRIMSRESIDENTIAL RAKERRT - Girth 10.75" RAKE, GABLE, EAVERAKE & CORNERCOR - Girth 13" MINI RESIDENTIAL RAKERRTM - Girth 8" 2121221212PAINT PAINT PAINTGUTTER APRONGA - Girth 5.5" Specify pitch.RESIDENTIAL DRIP EDGERDC - Girth 9.5" 90° pitch if not specied. FASCIAFT - Girth 9" Specify pitch.pitchpitch2"3"½"pitchPAINTPAINT PAINTVALLEYVT1 - Girth 19.75" VALLEYVT2 - Girth 20.75" pitchPAINTpitchPAINTVALLEYUnless otherwise noted, trims come in 29 or 26 gauge, and all angles are 90° or 45°. See page 11 for gauge and color codes.RIDGE CAPRCP - Girth 13.75" RIDGE CAP - Specify pitch.Recommended for 6:12 or less.RIDGE CAPRC2 - Girth 20.75" Recommended for all pitches.RESIDENTIAL RIDGE CAPRRCP - Girth 17" pitch8"8"PAINT½" hempitch¾"4 5⁄8"4 ½"9 ¾"PAINT15⁄8"4"6 ¼"½" hempitch¾"PAINTPEAK PLATEPEAKP12"½"1"PAINTPEAK BOXLRPBOXF - 13"Standard 4:12.PAINTpitchHIP CAPHIP - Girth 9"PAINTPEAK PLATE REVERSEDPEAKPREV12"½"1"PAINTGABLEGT6 - Girth 16.5"PAINTRESIDENTIAL EAVERET - Girth 6.5" Specify pitch.pitchPAINT61º open hem PAINTFORMED RIDGE CAPPPFRCP - Length 3' 36"18"29 gauge only. Maximum pitch 4:12.Longer lead times may apply.

CENTRAL STATES MANUFACTURING, INC.Effective 05/2022 • Information subject to change 13ROOF TRIMSGAMBREL TRIM UPPERGTU - Girth 10.25" TRANSITION TRIMS - Specify pitch.GAMBREL TRIM LOWERGTL - Girth 10.25" GAMBREL TRIM LOWERGTL2 - Girth 14.5" PAINTPAINTpitchPAINTUNIVERSAL SIDEWALLSF1 - Girth 9.25"PAINTUNIVERSAL ENDWALLEF - Girth 12.5" pitchPAINTpitchENDWALL FLASHINGEFF - Girth 12"PAINTINSIDE CORNERIC1 - Girth 13" J-TRIMJT - Girth 4.8125" WINDOW DRIP CAPWC - Girth 3.75" FLAT SHEETFS9 - 29 gauge. Girth 43"FS6 - 26 gauge. Girth 41.5625"10 sheets or fewer will be packaged in a roll.Additional pallet charge on orders of 10 or more.PAINT PAINT PAINTUnless otherwise noted, trims come in 29 or 26 gauge, and all angles are 90° or 45°. See page 11 for gauge and color codes.Unless otherwise noted, trims come in 29 or 26 gauge, and all angles are 90° or 45°. See page 11 for gauge and color codes.WALL TRIMSRG1RGSQUARE BASESBA - Girth 5" RAT GUARDRG - Girth 4.75"RG1 - Girth 5.5625"PAINT PAINTRAKE & CORNERCOR - Girth 13" MINI CORNERMCRN - Girth 9.5" PAINT PAINT

CENTRAL STATES MANUFACTURING, INC.Effective 05/2022 • Information subject to change 14WALL TRIMSOVERHEAD DOOR JAMB 7 ⁄OHDJ7 - Girth 12.5" FRAMED OPENING TRIMSOVERHEAD DOOR JAMB 7 ⁄OHDJWD7 - Girth 12" With drip edge.OVERHEAD DOOR JAMB 9 ¼OHDJ9 - Girth 14.25" OVERHEAD DOOR JAMB 9 ⁄OHDJWD9 - Girth 14" With drip edge.PAINTDOOR POST TRIMDJ8 - Girth 12.5" DOOR POST TRIMDJ9 - Girth 13.5" 7 ¼"1 ⁄"1 ⁄"1 ½"PAINTPAINT PAINTPAINTPAINT67⁄8NTC NT2TRACK DOOR JAMBTDJT - Girth 14.375" SLIDING DOOR TRIMSSQUARE TRACK COVER NATLNTC - Girth 12.1875" NT2 - Girth 9.125" ROUND TRACK COVERCTC - Girth 13" DC1 - Girth 17.625" PAINT PAINT PAINTCTC DC1POST TRIMSA312 - Girth 5.5" SA512 - Girth 7.5"SA7 - Girth 9"SA712 - Girth 9.5"ANGLE For hem on other leg, refer to Residential Fascia Trim.PAINTINSIDE ANGLEIA112 - Girth 4" IA2X2 - Girth 5"IA3X3 - Girth 7"SINGLE ANGLESA112 - Girth 4" SA2X2 - Girth 5"SA3X3 - Girth 7"DOUBLE ANGLEDA1 - Girth 3.5" DA112 - Girth 5.5" Use with wainscot.PAINTPAINTUnless otherwise noted, trims come in 29 or 26 gauge, and all angles are 90° or 45°. See page 11 for gauge and color codes.DOOR EDGEDJ10 - Girth 11.25" PAINT9"1 ⁄"1 ⁄"1 ½"2 ½"1 ½"1"PAINTDA112DA1

CENTRAL STATES MANUFACTURING, INC.Effective 05/2022 • Information subject to change 15SOFFIT/FASCIAJ-TRIMJT - Girth 4.8125" Use to make F&J Assembly.SOFFIT JTRIMFASCIASOFFIT PANELROOF PANELDRIP EDGEBEADED FASCIAJTRIMSOLID ALUMINUM SOFFITWALL PANELSOFFIT F ADAPTORRESIDENTIAL FASCIA TRIMRFT312 - Girth 5.5" RFT512 - Girth 7.5"RFT712 - Girth 9.25"GABLE BASE SOFFITGB1 - Girth 20.25" SOFFIT F ADAPTORSFA - Girth 4.75" Random color. Use to make F&J Assembly.10.875” coveragePAINTPAINTPAINTPAINTF&J ASSEMBLY - (SFA & JT)Unless otherwise noted, trims come in 29 or 26 gauge, and all angles are 90° or 45°. See page 11 for gauge and color codes.ALUMINUM SOFFITVS(color) - VentedSS(color) - SolidPAINT½" hem15⁄8"15⁄8"15⁄8"15⁄8"15⁄8"15⁄8"1¼"1"1½"12"Painted side½" hem1⁄"1⁄"1⁄"1⁄"1¼"1½"8"½" hem1½"15⁄8"15⁄8"1¼"1½"6"½" hem1⁄"1¼"1⁄"1½"4"½" hem15⁄8"15⁄8"15⁄8"15⁄8"15⁄8"1¼"5⁄8"1½"10"BEADED FASCIA TRIMBFTW4 - Girth 6" BFTW6 - Girth 8" BFTW8 - Girth 10" BFTW10 - Girth 12" BFTW12 - Girth 14" 29 ga. only.29 gauge only. Length 12'.½" HEM1⁄"1"2"⁄"2⁄"FC12 FC382 ⁄"2 ⁄"⁄"1"⁄"2 ¼"½" HEMSOFFIT J-TRIMSJT - Girth 3.625" SOFFIT F&JSFJ - Girth 9.375" PANEL-LOC PLUS F&JPFJ - Girth 9.125" F CHANNELFC12 - Girth 7.5"FC38 - Girth 7.375"2"¾"⁄"½" HEMPAINTPAINT PAINT PAINT

CENTRAL STATES MANUFACTURING, INC.Effective 05/2022 • Information subject to change 16BUTYL TAPEInstall between fastener and exposed edge.Rolls per box may vary by location and vendor. Check with your sales person for details.Recommended for Panel-Loc Plus.TOUCH UP PAINTTP(color) - SMP, 0.6 oz. bottle w/brush.12PURSP - Purlin paint, 12 oz. spray.PART # LENGTH WIDTH THICKNESS ROLLS PER BOXBT3/8 45' 3/8" 3/32" 40BTR 40' 7/8" 3/16" 10BTL 45' 3/4" 3/32" 24SEALANTPART # SIZE COLORMRS10(color) 10.3 oz. tube call for colorsMRS10CLEAR 10.3 oz. tube clearDOOR SET - With steel jamb.3068DR - 38" x 81 ⁄"KNOBDoor knobs sold separately.TYPE PART # LENGTH DIAMETER HEAD COLOR #BAGMETAL/WOOD 1(color)MW 1" #10 1/4" Hex all 250METAL/WOOD 112(color)MW 1 1/2" #10 1/4" Hex all 250METAL/WOOD 2(color)MW 2" #10 1/4" Hex all 250METAL/WOOD 212(color)MW 2 1/2" #10 1/4" Hex all 250METAL/WOOD 3(color)MW 3" #10 1/4" Hex all 250METAL/WOOD STITCH 34(color)ST 3/4" #12 1/4" Hex all 250METAL/METAL 34(color)MM 3/4" #12 5/16" Hex all 250METAL/METAL 114(color)MM 1 1/4" #12 5/16" Hex all 250METAL/METAL 2ZMM 2" #12 5/16" Hex galvanized 250METAL/METAL LAP 78(color)LAP 7/8" #14 5/16" Hex all 250LOW PROFILE WAFER HEAD 1WFAST 1" #10 #2 Square drive galvanized 250POP RIVET POPcolor) 1/8" ALL 100Fastener color availability may vary by location, contact your sales consultant for details. Order fasteners in increments of 250 pieces.FASTENERSACCESSORIESPROFILE RIDGE VENTPPVENT - Net free area 23.3sq.in/ftLength 100'. Width 3". Thickness 1". Ridge CapPPVENT

CENTRAL STATES MANUFACTURING, INC.Effective 05/2022 • Information subject to change 17ACCESSORIESSquare - Max temperature 250°.MPF - Pipe size .25" to 5" MPF2 - Pipe size .25" to 3"MPF4 - Pipe size 3" to 7"MPF6 - Pipe size 4.75" to 10"MPF7 - Pipe size 6" to 12"MPF8 - Pipe size 6.75" to 14"MPF9 - Pipe size 9.5" to 20.5" MASTER PIPE FLASHING - Install in a diamond shape and not parallel to the rib.Silicone - Gray. High temp max 500°.4GSMPF - Pipe size 3" to 6.25"6GSMPF - Pipe size 5" to 9"8GSMPF - Pipe size 7" to 13"Square with zipper - Max temperature 250°.MPF1ZIP - Pipe size .5" - 4"MPF2ZIP - Pipe size 4" - 9.25"CLOSURES - Sold separately or by the box. Panel-Loc Plus outside closure shown.Closure is 1 3/8" tall and may require longer screws for installation.Item may vary from sample shown.INSIDE CLOSURE - Length - 3'. 100 per box.PPCLIN Panel-Loc Plus PPCLINGLUE Panel-Loc Plus - with adhesive 5VCLIN 5V - Length - 2' PPCLOUT Panel-Loc Plus PPCLOUTGLUE Panel-Loc Plus - with adhesive 5VCLOUT 5V - Length - 2' OUTSIDE CLOSURE - Length - 3'. 100 per box.CLOSURE VENT - Length - 3'. 25 rolls per box.PPCLV Panel-Loc Plus Panel-Loc Plus inside closure shown.Panel-Loc Plus closure vent shown.RETRO-EASERETROEASELength 300'.UNIVERSAL POLYFOAMPOLYG - With glue. 10-rolls per box.Length 25'. Width 1 1/2". Thickness 1 1/2". FLEXOVENTFLEXOVENT - (2) 10' rolls per box.Length 10'. Width 3". Thickness 1 1/2". GRAYFLEXGRAYFLEX-6 - 24-rolls per box.Length 20'. Width 1". Thickness 1". For use with hips and valleys. Skylight Washer - White.118WASHER - 100 per bag. ⁄" outside diameter, ¼" inside diameterDo not overtighten to allow for expansion of material.COVERAGE 36"Panel-Loc Plus - Clear PolycarbonatePPSKYPCC8 - Length 8'.PPSKYPCC10 - Length 10'.PPSKYPCC12 - Length 12'.Panel-Loc Plus - White PolycarbonatePPSKYPCW8 - Length 8'.PPSKYPCW10 - Length 10'.PPSKYPCW12 - Length 12'.SKYLIGHTS - For best results, use approved sealant (MRS10SKY) and washer (118WASHER). Skylights should be predrilled.Panel-Loc Plus skylight shown.Skylight Ridge Cap - UniversalRCPCC10 - Clear PolycarbonateRCPCW10 - White PolycarbonateLength 10'6"'. Width 25". Longer lead times may apply. Skylight Sealant - Clear.MRS10SKY 10.3 oz. tubeApproved for skylight use.6 1⁄8"¾"¾"3 ½"2 1⁄8"

CENTRAL STATES MANUFACTURING, INC.Effective 05/2022 • Information subject to change 18SLIDING DOOR1. Slotted Track2. End Cap3. Track Mount Bracket for Track & Cover4. Trolley5. Splice Clip6. Door Pull7. Stay Roller8. Door Stop9. Vertical Rail5342168479• 10STRK – 4• SPLCLP – 3• ENDCAP – 2• TRLYWRB – 2• SMB/CS – 21• DRPUL – 2• LTCH – 2• CTRCHLK – 1• 14VRTRL – 3• 14VRTRWH – 1• 10BRL – 2• 6BGRL – 2• CGWHD - 1• DRSTPVWC – 2• CTC – 4EXAMPLEThese are the parts needed for a 20’ wide door opening, with double doors, 14’ tall with track cover, using side mount brackets.To gure a sliding door you will need to know:1. What is the door opening width?2. What is the door height?3. Is it a single or double door?4. Do they want track cover?5. Do they want to attach the door using a side mount or top mount hanger?MINIMUM COMPONENTS NEEDEDDoor Track – You need twice the footage for the door opening. A 10’ door will need 20’ of track.Splice Collars – You need these to connect the track sections together.Trolleys – 1 Pair per door is usually enough.Track Hangers – Either side mount or top mount (with or without cover supports). Divide the total track footage in half and add one.EXTRA COMPONENTSEnd caps – One pair per each door opening. Vertical Rails – If it is a single door, two male vertical rails are needed. Length is determined by the door height. If it is a double door, three male rails and one female vertical rail are needed.Latches – Used to snug the door tight to the jambs when closed.Center Bar or Chain Latch – Use either one on a double door to close the door together at the center.Door Pulls – One needed per door.Door Stops – Used to stop the door from sliding too far.Bottom guide rail system – Either use the aluminum bottom rail for guide along with the bottom guide rail, or use the aluminum bottom rail for stayroller along with a stayroller. To gure amount of guide needed, take the length closest to 60% of the door width.Track Cover – Used to cover the sliding door track. Round track cover is used with a round track system. National track cover is used with a square track system. You need to make sure to use the track hangers with cover supports if track cover is used.

CENTRAL STATES MANUFACTURING, INC.Effective 05/2022 • Information subject to change 19SPLICE CLIPSPLCLPTRACK END CAPSENDCAPS - Sold in pairs.TOP MOUNT BRACKETTMBTMB/CS- with cover support.VRTRL100 - 10' AV MaleVRTRL120 - 12' AV MaleVRTRL140 - 14' AV MaleVRTRL160 - 16' AV MaleVRTWH100 - 10' HV FemaleVRTWH120 - 12' HV FemaleVRTWH140 - 14' HV FemaleVRTWH160 - 16' HV FemaleTMB/CSTMBSIDE MOUNT BRACKETSMBSMB/CS - with cover support.SMB/CSSMBDOUBLE SIDE MOUNT BRACKETDTBDTB/CS - with cover support.DTB/CSDTBCENTER DOOR GUIDECGWHD BOTTOM RAIL - FOR CENTER DOOR GUIDEBRL80 - Length 8'BRL100 - Length 10'BRL120 - Length 12'BRL140 - Length 14'BRL160 - Length 16'BOTTOM RAIL GUIDEBGRL60 - Length 6'BGRL80 - Length 8'BGRL100 - Length 10'STRK80 - Length 8'.STRK100 - Length 10'.STRK120 - Length 12'.STRK140 - Length 14'.SLOTTED TRACKTRACK MOUNTING BRACKETSDOOR GUIDE SYSTEM These three components are designed to go together as a guide system. Be sure to also order a Heavy Duty Stay Roller.VERTICAL ALUMINUM RAILSSLIDING DOOR

CENTRAL STATES MANUFACTURING, INC.Effective 05/2022 • Information subject to change 20SLIDING DOORThese two components are designed to go together as a guide system.HEAVY DUTY STAY ROLLERIncludes endcaps.TROLLYS - 2 per bagSLIDING DOOR ACCESSORIESDOOR PULLDRPUL - Available in white only.INSIDE DOOR STOPIDS HEAVY DUTY DOOR STOPDRSTPJAMB LATCH (cam latch)LTCHCENTER CHAIN LOCKCTRCHLKCENTER BAR LOCKCTRBARADJUSTABLE DOOR STOPDRSTPWVCPLATE TROLLYDSRLLRWRB - With roller bearing9.5" BOLT TROLLYTRLYWRB - With roller bearingAluminum bottom rail for stay roller.STYRLLR ABRL12 - Length 12'.

CENTRAL STATES MANUFACTURING, INC.Effective 05/2022 • Information subject to change 21NOTESWINDOW DRIP CAPJTRIMRAT GUARD/BASE TRIMINSIDE CORNERCORNEROVERHEAD DOOR JAMBANGLE TRIM1.5 X 1.52 X 23X3POST TRIM1.5 X 3.51.5 X 5.51.5 X 7.5TRACK COVERRIDGE CAPSOFFIT TRIMSIDEWALL FLASHRIDGE CAPFASCIA EAVE TRIM GUTTERRAKE GABLE TRIMENDWALLFLASHFASCIA EAVE TRIM GUTTER

CENTRAL STATES MANUFACTURING, INC.Effective 05/2021 • Information subject to change 22NOTES

HunterRusticGalvalume®‡BlackCharcoalBrilliantGrayPanel-Loc Plus™ - 29 gaugeClassic Color Selection ToolPanel-Loc Plus™40LIMITEDPAINTWARRANTYYEARCHRT_CLASSIC_240222EColors on this chart are close representations of actual metal color, limited by digital color reproductive capabilities and viewing conditions.‡ Weathering and appearance variation, including color, sheen, and spangle, is common in non-painted materials and is not a cause for rejection. For consistent appearance, choose a paint-nished product. Copyright © 2023, Central States Manufacturing, Inc., All Rights Reserved. centralstatesco.com

Commodity Color Selection ToolHunter RusticBurgundyOceanIvoryLight StoneTanBrownAlamo BrilliantCharcoal GrayBlack Forest CHRT_CMDTYL_240222ENon-warranty productCopyright © 2022, Central States Manufacturing, Inc., All Rights Reserved. Colors on this chart are close representations of actual metal color, limited by printing and viewing conditions. Color matching is optimized for outdoor viewing. Panel-Loc Plus™ centralstatesco.com

Panel-Loc Plus™ Color Selection ToolClear acrylic coatingGalvalume®‡ STANDARD | PRIME | ULTRAHunter STANDARD | PRIME | ULTRADesert PRIMETrim in 26 ga. only. Taupe STANDARD | PRIME | ULTRALight Stone STANDARD | PRIME | ULTRAColony PRIMETrim gauge variesby locationCrimson PRIME | ULTRARustic STANDARD | PRIME | ULTRABurgundy STANDARD | PRIME | ULTRAGallery PRIME | ULTRAOcean PRIME | ULTRATrim in 29 ga. only. Ivory PRIMETrim in 29 ga. only. Alamo STANDARD | PRIME | ULTRATrim in 29 ga. only.Pewter PRIME Trim in 29 ga. only.Brilliant STANDARD | PRIME | ULTRACharcoal STANDARD | PRIME | ULTRAGray STANDARD | PRIME | ULTRATan STANDARD | PRIME | ULTRABlack STANDARD | PRIME | ULTRAULTRA may not beavailable in all locations.Forest STANDARD | PRIME | ULTRABrown STANDARD | PRIME | ULTRABurnishedSlate STANDARD | PRIME | ULTRACHRT_PLPL_240508ECopper Metallic*† PRIMEChoose CentralGuard for the best protection and a lifetime warranty.*Contact your salesperson for accurate pricing. † Color variation between orders is normal and not cause for rejection. ‡ Weathering and appearance variation, including color, sheen, and spangle, is common in non-painted materials and is not a cause for rejection. For consistent appearance, choose a paint-nished product. Colors on this chart are close representations of actual metal color, limited by printing and viewing conditions. Color matching optimized for outdoor viewing. Clear acrylic coatingGalvanized‡ STANDARD | PRIME | ULTRACopper Metallic† PRIMEFluropon® 70% PVDFcentralstatesco.com

Choose CentralGuard®for the best protection anda lifetime warranty.Copyright © 2024, Central States Manufacturing, Inc., All Rights Reserved.CentralGuard® is a trademark of Central States® Manufacturing, Inc.Galvalume® is a registered trademark of BIEC International, Inc.CentralGuard is our specic combination of everything that goes into making the highest-quality metal panels. Available on ourPrime and Ultra panels, the CentralGuard name guarantees that you have the best protectionand a lifetime paint warranty.Choose CentralGuard for the perfect balance of fade protection, rust blocking, and dent resistance. Get started quickly with our preloaded photos, or upload your own photo. When you nd the perfect combination of panel and color, you’ll receive a summary of your project and have the option to connect with a local expertin your area to help you with your purchase and installation. visualizer.centralstatesmfg.comExplore our visualizer.Panel-Loc Plus™ 171⁄2 ”171⁄2 ”STANDARDPRIME ULTRACentralGuard CentralGuardFADE PROTECTIONPaint Warranty 40-YEARLIFETIME LIFETIMEPaint Thickness THICK .90 milTHICKER 1.0 mil THICKER 1.0 milFade Warranty 30-YEAR30-YEAR 30-YEARFade ProtectionP P PRUST BLOCKINGAdvanced Rust Blocking –P PPerforation Warranty –50-YEAR 50-YEARSubstrate Thickness 1.12 mil1.60 mil 1.60 milSubstrate Coating AZ35** Galvalume GalvalumeDENT RESISTANCEAdvanced Dent Resistance –P PPSteel Thickness THINTHICK THICKESTSteel Gauge 29 ga.29 ga. 26 ga.OUR BEST SELLER!Panel-Loc Plus features UL2218 approval for impact resistance and may qualify for a homeowners insurance discount. See your local insurance agent for qualications.** Check with your local permitting oce for restrictions and qualications.

RusticPRIME G90BurgundyPRIME G90GalleryPRIME G90Light StonePRIME G90TaupePRIME G90BrownPRIME G90Burnished SlatePRIME G90AlamoPRIME G90GrayPRIME G90BrilliantPRIME G90CharcoalPRIME G90HunterPRIME G90‡GalvanizedSTANDARD G90Clear Acrylic coatingChoose CentralGuard for the best protection and a lifetime warranty.Panel-Loc Plus™ Galvanized Color Selection ToolAVAILABLE IN 29 GAUGEPAINTED G90‡ Weathering and appearance variation, including color, sheen, and spangle, is common in non-painted materials and is not a cause for rejection. For consistent appearance, choose a paint-nished product.Colors on this chart are close representations of actual metal color, limited by printing and viewing conditions. Color matching optimized for outdoor viewing.CHRT_PLPLG90_MCCL_240222EPanel-Loc Plus™ centralstatesco.com

GalvanizedG40.40 oz (0.68 mil*)GalvanizedG60.60 oz (1.02 mil*)GalvanizedG90.90 oz (1.53 mil*)Copyright © 2023, Central States Manufacturing, Inc., All Rights Reserved.CentralGuard® is a trademark of Central States® Manufacturing, Inc.Galvalume® is a registered trademark of BIEC International, Inc.Choose CentralGuard® with Galvanized G90 for advanced rust protection.CentralGuard is our specic combination of everything that goes into making the highest-quality metal panels. The CentralGuard name is a guarantee that you have the best protection and a lifetime paint warranty.Our Prime G90 panels have a galvanized substrate made of rust-inhibiting zinc metal. This zinc coating protects the steel core from corrosion at any exposure point. The thicker the layer of zinc, the better the protection. Our painted Prime G90 oers the highest level of protection with 1.53 mil of rust blocking coating.Choose CentralGuard for the perfect balance of fade protection, rust blocking, and dent resistance. ThickestRust BlockingLayerGet started quickly with our preloaded photos, or upload your own photo. When you nd the perfect combination of panel and color, you’ll receive a summary of your project and have the option to connect with a local expertin your area to help you with your purchase and installation. centralstatesco.comExplore our roong visualizer.

Texture Color Selection Tool Choose CentralGuard for the best protection and a lifetime warranty E CHRT_TEXTURE06L_240222 SMP WITH TEXTURE Horizon-Loc™ - PRIME 26 ga. Hidden fastener Panel snaps Panel-Loc Plus™ - PRIME 29 ga. Contact your sales person for accurate pricing. Longer lead times may apply. Texture panels must be installed in the same direction. See directional arrows or stickers provided on your panels. Color variation between orders is normal and not cause for rejection. Colors on this chart are close representations of actual metal color, limited by printing and viewing conditions. Color matching is optimized for outdoor viewing. Roma Sienna Sumatra Onyx Mineral centralstatesco.com Basil

Copyright © 2024, Central States Manufacturing, Inc., All Rights Reserved. CentralGuard® is a trademark of Central States® Manufacturing, Inc. Upgrade to Texture for a new depth of color and added durability. The granular finish of SMP with Texture combines a matte appearance with shimmering tones to provide a depth of color never before seen on traditional metal panels. Plus, our Texture finish features Central Guard®, our specific combination of everything that goes into making the highest-quality metal panels. It is a guarantee that you have the best protection and a lifetime paint warranty. Choose Texture for a look similar to traditional shingles with the benefits of a metal roof. SMP with Texture Mineral Traditional SMP Charcoal Notice how the light reflects off our traditional smooth finish creating a glare, but the Texture finish breaks up the light to give a deeper, richer color. • Mimics the texture of shingles. • Reduces glossiness and glare often associated with metal roofing. • More scratch resistant. • More slip resistant during installation. • 26 ga. matching trim.

HunterRusticGrayCharcoalLight StoneTanBrownPolarPanel-Loc Plus™ - 26 gaugeR-Loc™ - 26 gauge M-Loc™ - 26 gaugeThrifty Color Selection ToolPanel-Loc Plus™M-Loc™R-Loc™50LIMITEDPAINTWARRANTYYEARCHRT_THRL_240219EColors on this chart are close representations of actual metal color, limited by printing and viewing conditions. Color matching optimized for outdoor viewing.Copyright © 2024, Central States Manufacturing, Inc., All Rights Reserved. centralstatesco.com