Return to flip book view

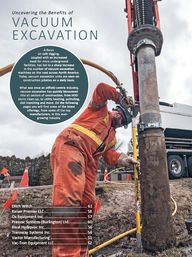

Uncovering the Benefits of VACUUM EXCAVATIONA focus on safe digging, coupled with an increased need for more underground facilities, has led to a sharp increase in the number of vacuum excavation machines on the road across North America. Today, vacuum excavation units are seen on construction jobsites on a daily basis.What was once an oilfield-centric industry, vacuum excavation has quickly blossomed into all sectors of construction, from HDD slurry clean-up, to utility locating, potholing, slot trenching and more. On the following pages you will find some of the latest offerings, from some of the top manufacturers, in this ever-growing industry.Ditch Witch ................................................. 61Kaiser Premier LLC ...................................... 58Ox Equipment Inc. ...................................... 57Presvac Systems (Burlington) Ltd. ............... 60Rival Hydrovac Inc....................................... 56Transway Systems Inc. ................................ 54Vactor Manufacturing ................................. 51Vac-Tron Equipment LLC.............................. 52

WWW.TRENCHLESSTECHNOLOGY.COM 57Currently the industry standard for safe excavation technologies throughout Europe and the United Kingdom, and now available across North America, dry suction excavation powerfully excavates without the use of water, eliminating issues related to slurry disposal as well as overweight loads. Ox Equipment Inc. is the exclusive distributor for industry leading MTS GmbH Dry Suction Vacuum Excavators, and contractors and clients are quickly realizing the benefits of digging dry. Recently, a California-based contractor was selected to safely excavate 350 cubic yards of dry soil within an isolated and secure valve yard, an excavation that ranged up to seventeen feet below ground surface. Due to safety concerns, the client did not permit mechanical excavation equipment anywhere on site. While a traditional hydro vac is capable of safe digging, this was not the client’s preferred choice due to the required travel distance and time for ongoing slurry disposal and water refilling. =Utilizing their innovative MTS Dino Series dry suction excavation unit, the contractor was able to achieve production rates of 40-70 yds2 of soil per day, with the dry soil being unloaded at the project site for future reuse. Digging dry and staying on site, the contractor completed the entire project safely and well ahead of schedule, all at a considerable savings to the client.The Dino Series Suction Excavator utilizes a proprietary twin fan system which generates over 24,000 CFM of suction power. The large 10” diameter suction hose, which is precisely manipulated via a fully mechanical Power Arm, deploys off the rear of the unit for increased versatility. Functional side-tipping allows for fast, efficient and easy dumping from the 10.5 cubic yard spoils container, either directly on-site or into roll-off bills, allowing the unit to stay on site all day effectively doubling productivity. Contact Ox Equipment Inc. for more information or to arrange an on-site demonstration. 1-888-290-4044 www.ox-equipment.comSPECIAL VACUUM EXCAVATION FOCUSMTS Dino Series Suction Equipment Sets the Standard for Vacuum Productivity By Colin DonoahueADVERTORIAL