Return to flip book view

Rubix April 2021 Issue 21 Inside this issue Construction progress BOC Handler WH Table Milestones Manufacturing Procurement Project timeline Health Safety Wellbeing

Contents Project timeline 2 Project Update 3 BOC Handler 4 Construction 6 Milestones 10 Manufacturing 13 Procurement 20 Quality 22 Security 23 Transformation 24 Wellbeing 25 Health Safety 26 Project timeline Where we are and where we are going A simplified graphic of project progress 2

Project update At the beginning of 2021 the project set itself targets to deliver over the next 12 months 15 key milestones including 2 for Engineering These have been shared with the project and our key stakeholders and everyone working on the Project has a vital role in delivering them The first 3 have now been achieved either on or ahead of time including most recently the installation of the BOC Handler 2 months ahead of schedule These have been excellent achievements delivered through the hard work and effort of everyone on the BEP Project and across our Supply Chain In addition to demonstrating our commitment to delivering the Project to the earliest practical date they help us build up a workbank for Construction to facilitate the transition of the Project to a more Construction focussed delivery All of the remaining milestones with the exception of the 2 Engineering milestones involve equipment installation The focus for this year is clearly on getting equipment out of our supply chain and onto site The photos of the equipment at our supply chain clearly demonstrate this intent To deliver on all of the above and to complete the Project to the earliest achievable date the key challenge for this year will be getting people back safely on site at Sellafield and to exceed the pre Covid 19 workforce numbers We are already gradually increasing numbers in April with plans for further increases in June The ultimate aim is to have to have a substantial increase in the team as and when the Covid 19 working constraints are relaxed Whilst we have a clear focus on delivery our overarching priority remains keeping all of our staff and those we come into contact with safe and well With Covid 19 this last year has been very challenging for everyone involved Impacting upon both our physical and mental wellbeing We have all had to adapt whether it is working on site in the office factory or at home As a project we have performed exceptionally coming up with procedures and arrangements which have been adhered to by all and have kept everyone safe from Covid 19 and enabled us to continue to deliver throughout To date we have not had a single case of work related transmission Hopefully with the vaccination role out we can now look forward to a new normal Covid has obviously absorbed a lot of our attention but as equally important has been our focus on conventional safety Throughout the pandemic we have continued working with Dekra our behavioural consultants at the Sellafield Site looking at how we can change behaviours and our culture to deliver improved safety performance as we look forward to achieving our 2 million project working hours landmark The current focus of this engagement is to raise the standards and expectations of management and supervision personnel which will then have a positive effect on the behaviours of the workforce through the application of a coaching methodology This work will continue for the next 12 months In June 2020 the Project commenced a process of transformation to improve the performance of the Project through collaborative working The Project initially identified eight initiatives for improvement to be progressed and as the process developed we identified a further seven initiatives You can read more about these in the later section on Transformation Work on all fifteen of these has progressed and whilst some of these are long term initiatives benefits are already being realised in particular relation to Construction delivery This work will continue throughout 2021 to building upon the achievements we have already made Bill Holmes JV Project Delivery Director 3

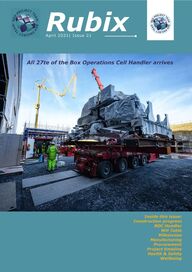

BOC Handler Delivery and installation 16 17th March A significant milestone has been achieved on the BEP Project with the safe delivery and installation of the Box Operations Cell Handler The achievement of this milestone is a result of some excellent team work The careful planning and the enabling works completed prior to delivery has helped to ensure that the installation was safely executed The combined and collaborative efforts of SL BEP JV Mammoet and Wellman Booth was a great example of one team working towards the same goal Due to the tight space within the facility the Handler was loaded onto a Self Propelled Modular Transporter SPMT driven into position jacked up on temporary rails to then tirfor into position on the permanent rails Well done to all for safely delivering and installing this major plant item into the facility ahead of the milestone date Shaun Birkett JV Delivery Manager 4

BOC Handler Delivery and installation 16 17th March 5

Construction progress inside View west over Box Operations Cell and Waste Treatment Cell View west over the Box Operations Cell BOC 6 Inside the Box Operations Cell

Construction progress inside Top of Waste Treatment Cell view east View north of System 133 Bogie rail studs for the Internal Transit Flask rails and shield doors Top of Waste Treatment Cell view north Detail inside the Box Operations Cell left East side of the Waste Treatment Cell view north 7

Construction progress outside View west of the east side of the building Compressor House in scaffold and Grout Plant behind the crane with the steel frame of the Receipt Area to its right View east of west side steel frame in front of the Grout Plant behind the Receipt Area to the left of the photograph New staircase and gantry to the main facade 8

Waste Handling Table Installed 5 months early Following the delivery of the Waste Handling Table one week ahead of the milestone date both the table and backslope were successfully installed into the facility building by the Site Team led by Jason Adair The complex and large plant items were loaded into cell via a Temporary Construction Access Opening TCAO To achieve this several in depth reviews with Construction and Engineering were undertaken The revised Engineering Order and lifting plans approved in record time Once within the Waste Treatment Cell the table was temporarily located into position to confirm fit with the pre installed table legs No issues were encountered The Waste Handling Table and Backslope are safely stored in cell in readiness for installation some five months ahead of the original planned installed date This is a great example of a successful collaborative effort from all involved Gary Hope Area Project Manager 9

2021 Milestones Our major goals for the year are set out below 15 in total Including Major Engineering Milestones 28th MAY 2021 Design Freeze of major documents 30th SEPTEMBER 2021 JV Detail Design complete DATE MILESTONE TYPE ACTIVITY ID APM LEAD 08 02 2021 Delivery of Air Compressors EWG PR36 1QA4 PW KS 16 03 2021 In cell Stands Fabrications Waste Handling Table Supply Pkge 07 EWG PR07 30631 GH KS 24 5 2021 EWG CBCM0331510xx GH SB 29 07 2021 Locate System 121 Bogie on to Rails NDA CWCM0217510c GH BoM SB 06 08 2021 Install System 131 Bogie Rails EWG C1311691430 VF SB 06 08 2021 Waste Treatment Cell Install Maintenance EWG CWCEquipment Grid Line11 9 M0214600yx 520 Hatch SS Cladding local Kit 06 08 2021 System 131 Rails completed NDA C1311691430 BoM GH SB VF SB 06 08 2021 Waste Treatment Cell Works to allow Long Wheel Base Handler move to be completed 12 8 2021 Waste Handling Robots ready to deliver Pkge 10 NDA CWCM0214600y GH BoM SB EWG PR10 90061 GH KS 22 09 2021 Active Effluent Cell Temporary Construction Area Opening TACO 21 Phase 1 Closure 07 10 2021 System 133 Rails completed NDA CZZTCAO69370 BoM JD SB NDA C1331182720 BoM NDA Not currently a milestone SL bonus with the NDA BoM CWCM0212341 VF SB JD SB GH SB Box Operations Cell Maintenance Install BOC Handler onto the rails 22 11 2021 Installation of electrical and instrumentation primary containment in the whole BEP building at 85 c 9 775 linear metres 14 01 2022 Vertical Cell Door Raise Door on Recovery System and move Long Wheel Base Legend BoM Basket of Measures EWG Executive Working Group APM PW Paul Williams GH Gary Hope VF Vince Fleming JD Jeff Dutton Lead Team KS Kevin Smith SB Shaun Birkett R2 15 3 23 BoM revision number removal 10

2021 Milestones 1 Delivery of Air Compressors In March 2019 Atlas Copco were appointed to design and supply Compressed Air Equipment to BEP During the vendor design stage it was identified that there was potential air quality issues with the initial equipment selected and a change in the necessary operating range of the compressors became apparent This meant reworking the design and the introduction of additional hardware which initially proved difficult to configure but a solution was found and the equipment was successfully accepted for installation During the Factory Acceptance Test of this equipment 17 20 November 2020 the compressor sequencing panel did not control the compressors as anticipated This resulted in configuration changes being needed and retesting on the 16th December 2020 Issues were identified regarding air flow rates and pressures which instigated a minor design change and final testing to prove the equipment operated as required was undertaken on the 13th January 2021 This amount of design change and additional testing challenged the site delivery date further in addition to the high quality requirements of the equipment and the added complication of necessary restrictive pandemic working practices None the less by working collaboratively as a team the above issues were resolved quickly and pragmatically and avoided major increase in hardware cost and schedule delays The Compressed Air Equipment was successfully delivered to site on the 8th February From Atlas Copco and CPE in line with the declared milestone The first of fifteen milestones planned for the year Special thanks go out to Marcus Eves Senior Project Engineer Josh McGarry Process Lead Engineer Chris Clarke Package Lead Engineer Glyn Oxley Control Electrical Instrumentation Engineer Stuart Brady Quality Control Engineer Graham Drewery Client Process RE Ged Pitts Expediter and Gurinder Mangat Atlas Copco Project Manager who without their commitment professionalism and delivery mind set has meant successful completion of this milestone Job Well done Paul Williams Area Project Manager February 2021 11

2021 Milestones No 2 Waste Handling Table delivered 5 days early The Waste Handling Table forms the centrepiece of the Waste Handling Area which enables BEP to conduct various waste sorting and disruption operations whilst capturing any emitted effluents and losses The WHT design has been developed in collaboration with North West Projects Ltd BEPDT and Sellafield and was informed by Learning From Experience from the System 221 Trials at NNL Workington using a carbon steel replica Subject Matter Experts SMEs from Sellafield Inspection Certification Group were also heavily engaged during the design process with regards to material selection and applicable standards The self delivered Build to Print design of the WHT was issued to WEC Group for manufacture on 15 03 2019 and throughout the design and tender stage it was acknowledged that the table would be difficult to manufacture The table is a large fabrication 4 5m x 2m constructed with a Duplex deck a material that is notoriously difficult to work with whilst maintain dimensional stability The table also has a challenging flatness requirement to prevent pooling of liquors on its surface and the whole fabrication was subject to quite onerous engineering standards to ensure a prolonged service life within an active Cell From the outset of the manufacture contract these challenges were recognised by the project team who subsequently committed to the production of a 1 3rd size test piece to develop the complex manufacturing techniques that would be required to minimise and control the level of distortion within the main table slab The table incorporates an extensive welded lattice structure on its underside to provide its required strength with the design allowing for final machining of the top face to compensate for any distortion during this welding process However the learning from the test piece when applied to the final fabrication minimised and controlled distortion so effectively that the final machining of the table top face was not required The table was predominantly manufactured during COVID 19 restrictions but an excellent working relationship with the project team and WEC was maintained throughout the contract The combination of a truly collaborative team focused on effective delivery and the all round capabilities of WEC Group has resulted in the success of this challenging project Thanks to everyone involved Paul Blood Delivery Engineering Manager Gary Hope APM Kevin Smith Delivery Manager Adrian Radcliffe WEC Operations Manager Jason Carter Package Manager Alan Christopherson Package Lead Engineer Justin Cranston ICG Inspection Mike Silver SL IC Martin Banton SL Quality Assurance Subject Matter Experts Brendon McGarry Dan Corby Dave Campbell Paul Whiteside Kristian Stephens and Chris Hogan 12 Key collaborators Ian Pickup Matt Peckford Bill Jones Trevor Joy Paul Evans and Chris Embleton

Manufacturing Shield Door fabrications door plinths Month on month this year the large engineering components are taking shape Here you can see the designs from the BIM model turned into the reality Shield Door fabrications door linkages Lead screw installation frame and unpainted lifting beam 13

Manufacturing cont Waste Handling Table back slope assembly Swab Containment Box

Manufacturing cont Liner Import Hatches and Plugs from model to installation Skip Adapter Frame 15

Manufacturing cont Grout Bogie System Outcell Drive Assembly Handler Scheilf rings

Manufacturing cont Box Export Hatch and Drive System 221 Factory Acceptance Testing FAT Rig 17

Manufacturing cont Door Recovery Systems

Manufacturing cont Waste Handling Robots Primary Tool Stands 19

Procurement BEPJV Supplier Relationship Management The SRM programme is focused on behaviours and attitudes towards collaboration and relationships delivered through the engagement of key individuals across the project Mike Preston of The Herne Group who have been brought in to assist in the matter said We use a mix of questionnaires interviews and candid discussions with vendors and BEP package team members to gain a 360 view of relationships as well as workshops meetings and training to develop collaborative behaviours We have identified areas to address as well as uncovering some very strong relationships and positive examples of collaborative working In some cases suppliers and the JV have completed the training together which is great for accelerating team development The simulation training specifically is intense time pressured and reveals true behaviours under pressure allowing for reflection of individuals collaborative behaviours and relationship management skills Progress to date Vendors and JV team members have expressed their support for SRM and appreciate the chance to discuss these matters Data collected so far has led to a wider understanding of each other s challenges and encouraged collaborative approaches to overcome them with a one team mindset focussed on delivery and mutual benefit Some examples of findings identified Identified the problems were more structural systemic than socio political almost all vendors feel the BEPJV operational teams are committed hard working well meaning and supportive Regular changes in BEPJV personnel can disrupt relationships and put things back Early engagement to set the collaborative scene and conduct a thorough technical review is essential CRAFT model Relationship Cycle 20

Procurement cont There are also plenty of examples of good work and strong collaborative relationships Working with the BEP project team works well and collaborating with them is a breath of fresh air BEP Supplier In 20 years I cannot think of a more collaborative supplier they are fully committed and move heaven and earth to support us BEPJV Package Manager Moving forward THG is now working with BEP to set up work streams to address collaborative barriers in each package Also workshops meetings to develop collaborative objectives behavioural charters and package collaboration checklists to support new and existing packages Successful implementation of the desired behavioural shift takes persistence consistency and time THG and BEP aim to continue to train individuals in collaborative behaviours share good practice across the project and exploit success recognising good relationship management and collaborative Programme Objectives Focus Collaboration predictability of outcome benefit for all Areas of interest Collaboration Relationships and Trust Encouraging people to go first and engage in healthy conflict to es tablish clarity and accountability Commitment to delivering measurable results Wanted Programme Outcomes Create value for both parties that go beyond what is contracted Managed engagement at an executive level Development of joint strategic objectives for the relationships Work in a way that recognises and promotes mutuality Adopt more collaborative behaviours and ways of working 21

Quality HVAC System Delivery Despite a number of challenges faced by the subcontractor MC Air contracted in by Hargreaves they have successfully completed the manufacture of 16 dampers and 38 HEPA filter units for some of the specialised environments which the BEP facility contains A collaborative team effort to overcome specification challenges welding purge issues COVID 19 restrictions and other workload pressures With over 600 inspection activities in eight Inspection and Test Plans ITPs have all been signed concurrently with manufacture and all units together with the associated Long Term Records are complete and awaiting final shipment for installation to site Special thanks go to B Haslam CamFil Works Manager D Clark MCA H Wilson Quality Control Inspector and Paul Thomas Hargreaves Quality Assurance Manager for going the extra mile to ensure a successful outcome and reach solutions for some difficult challenges Extract Secondary HEPA Filter Housings outlet and inlet being prepared for delivery above C5 Extract Primary Remote HEPA Filter Housings packed ready for dispatch left Within Engineering the teamwork and increased visibility is also reaping rewards as the number of packages issued by the Joint Venture for Sellafield Ltd approval has increased over the last five months and the response times for package approvals Project Managers Acceptance Contract Design PMACD and Contractors Acceptance Suppliers Design CASD continue to reduce enabling the commencement of manufacture and placement of contract awards in line with procurement Shaun Lees JV Quality Manager IFR IFA Inspection For Review Inspection For Acceptance 22

Security Audit The Office for Nuclear Regulation ONR recently conducted an audit of the BEP Delivery Teams security arrangements at Washington House as part of their civil nuclear supply chain audit programme for locations where Sensitive Nuclear Information SNI is held Due to Covid 19 the first part of the audit was conducted remotely via MS Teams with a follow up visit to the office conducted a few days later During the audit the ONR conducted a detailed review of the BEP Delivery Teams physical personnel information security controls and our security governance arrangements The outcome of ONR audits are rated in accordance with a traffic light system of Red Amber Green The BEP Delivery Team were rated Green meaning that no significant shortfalls were identified in the delivery of the security function and there are no mandatory follow up actions to address This is a great result and thank you to Shaun Lees and Jamie Harnett for their assistance and participation in the audit Justin Gillies BEP Security Manager SC DC Clearance and Social media We have some 20 000 people including ASWs CSWs and contractors who are either SC or DV cleared Our security regulator ONR CNSS has asked us to remind people that we should not disclose our level of security clearance on line or on social media profiles in particular on recruitment apps such as Linked In This requirement is outlined in the letter sent by ONR CNSS on the issue of your clearance The letter also explains that you have been vetted because your role requires you to have access to sensitive information or assets or places you in a position of trust Therefore our security regulator wants us all to review our social media profiles and remove any reference to our security clearance status Failure to conform with this requirement could ultimately lead to your loss of clearance so please check out what you ve posted on line Management of Contractors Department Notifications Sellafield Ltd 23

Transformation The core of all of the transformation effort has been clarity of outcomes at individual team and project levels to focus energy on the priority areas These have been key to achieving a number of successes over the last few months and BEP continues to strive for ever improving performance through the ongoing efforts across the project with the support of Transformation 5 Executive oversight and support A monthly Executive Working Group has been established between Sellafield CEO Martin Chown Balfour Beatty MD Stephen Tarr and Jacobs SVP Clive White which is providing oversight and support to the senior management teams 6 Meetings and reporting The key monthly and weekly meetings have been refocussed and continue to develop to meet the project needs a focus on outcomes being the priority and the introduction of time for looking forwards 7 Supply Chain engagement We ve engaged with our supply chain and taken the learning to help drive the strategy for the placement of our remaining orders The priority areas have all seen significant progress and impact 1 Project Management led model An improved focus on the EPCC Engineering Procurement Construction and Commissioning schedule through a realignment of the schedule under 4 Area Project Managers and the introduction of a line of sight process focussed by area This continues to evolve and embed and we expect further improvements as we progress 8 Opportunity management We re reinvigorating our pursuit of opportunities and providing adequate time and effort to realise the benefits they can bring 9 Collaborative working We have continued to focus on the relationships across the project supporting the development of performance driven collaboration on the live challenges leading to successful delivery of a number of key initiatives 2 Physical Area Co ordination With all appointments made a series of workshops held to review the lookahead schedule and the line of sight process led by the PACs Project Area Coordinators in conjunction with the construction teams we are ensuring alignment of everyone to the schedule and as a result we are seeing improved schedule adherence and milestones achievement We will undoubtedly encounter many challenges as we progress on our journey to safely deliver the BEP project at the earliest practicable date but our success will be dependent on how we collaborate and work together solve the issues and maximise the opportunities in front of us This means we all have a part to play focusing on our activities and interactions to achieve the best possible outcomes 3 Integrated Project Controls The project controls team are working in an integrated and collaborative way with significant improvements made in the availability and use of the information that is available including a revised EPCC monthly report We look forwards to continuing with you as we build on the progress made 4 Sellafield Ltd Client Model Delivery Clarity on the SL Client Model continues but we are already seeing a strong focus on shared outcomes by the JV and SL teams 24 The Transformation Team Terry Meighan JV Bill Holmes JV Jeff Gaines SL

Wellbeing What is self care Self care is any activity that we do deliberately in order to take care of our mental emotional and physical health Although it is a very simple concept in theory it is something we very often overlook Self care includes all the things you do to take care of your well being in four key dimensions your emotional physical psychological and spiritual health You cannot pour from an empty cup Self Care What It Really Is Susannah Winters https youtu be dBn0ETS6XDk https www ted com talks susannah_winters_self_care_what_it_really_is Don t forget our Mental Health First Aider team are spread right across the project Contact details are available on the IMS in the Covid 19 folder Or contact our Wellbeing Coordinator catherine melvin bepdt com Tel 01946 55 6282 Mob 07882465610 Whatever you talk about it is in confidence Alternatively Employee Assistance Services are available though your employer or independant bodies such as 25

26 Contact Email comms bepdt com Tel 01946 556263 Mob 07860 833 188